Linear-motion electromagnetic loading device

A loading device and linear motion technology, which is applied in the testing of measuring devices, instruments, and mechanical components, etc., can solve the problems that mechanical equipment is difficult to simulate loading, etc., and achieve the effect of simple structure, fast response and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

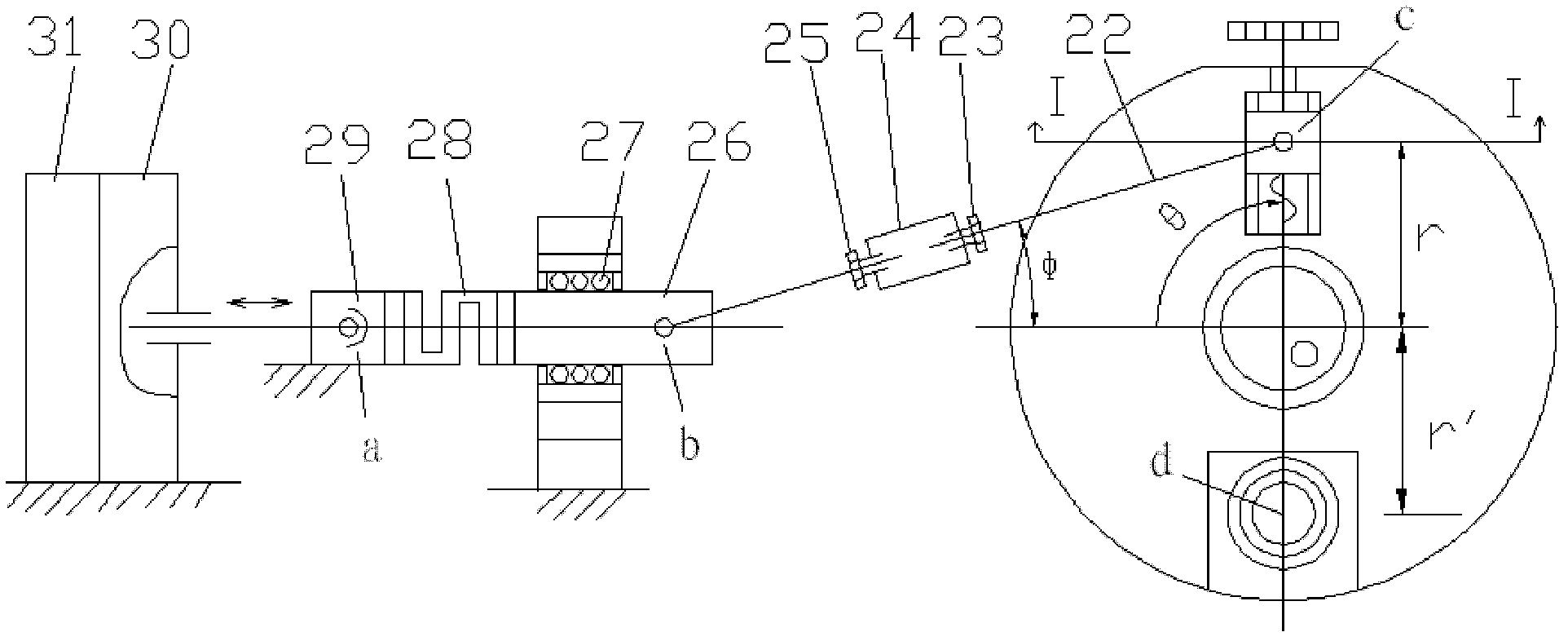

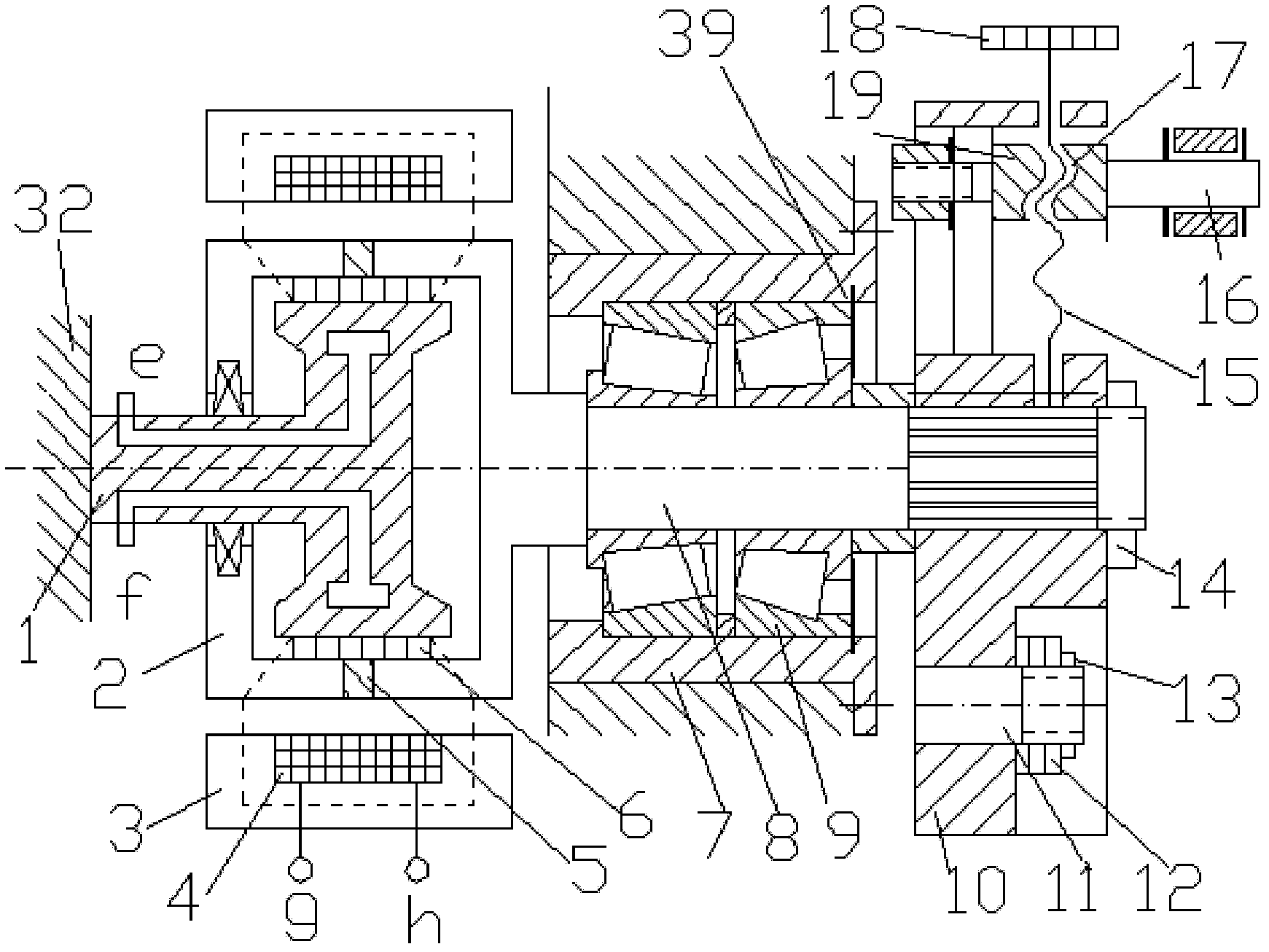

[0016] The structure of the device of the present invention is, comprises mechanical part and electrical control part, and mechanical part comprises link mechanism and magnetic powder loader part again, and the axle center of linear rolling guide bush 27 in the link mechanism and magnetic powder loader main shaft 8 is arranged on the working On the same height line as platform 32,

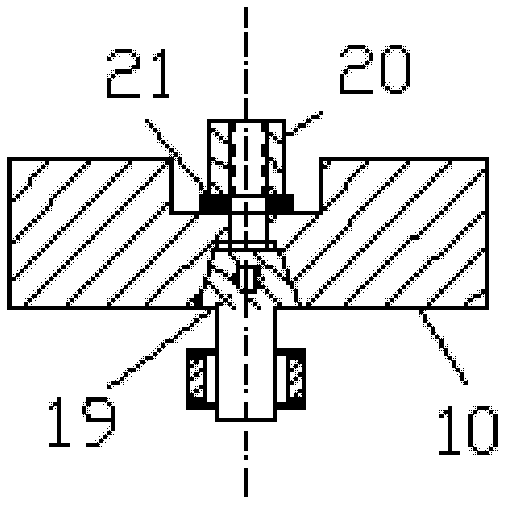

[0017] The structure of the link mechanism is to include a linear rolling guide bush 27, a loading head 26 is worn in the linear rolling guide bushing 27, and one end of the loading head 26 is sequentially connected with a one-way tension pressure sensor 28, a linear output member 29, and a loaded mechanism. 30. The prime mover 31; the other end of the loading head 26 is hinged with the left half connecting rod 38, the left half connecting rod 38 is threadedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com