Mechanical impact type fault diagnosis method based on variable space-scale frame

A variable space, fault diagnosis technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as unfavorable fault characteristics, difficult for technicians to understand, and poor practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

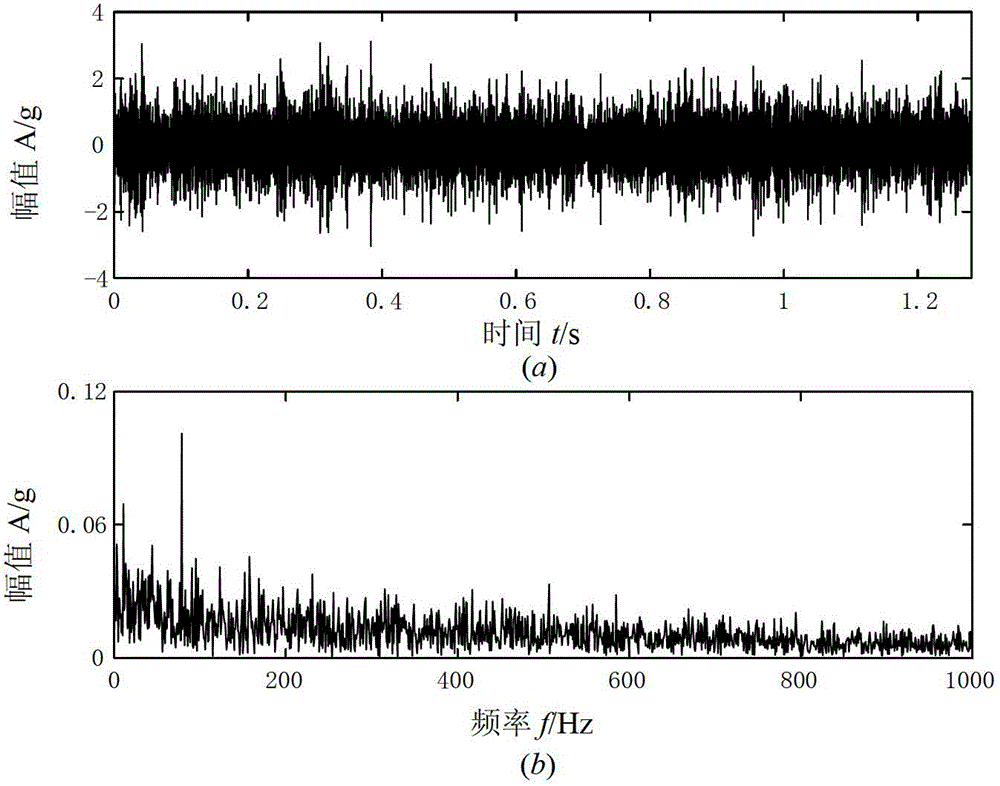

[0159] This embodiment mainly verifies the effectiveness and accuracy of the method of the present invention. The acceleration signal collected by the vibration acceleration sensor from the rolling bearing test bench of the locomotive running part, the rolling bearing model is 552732QT, and its structural parameters are shown in Table 1. The shaft speed is 653r / min, the sampling frequency is 12.8KHz, and the sampling length is 16384. According to the calculation formula of the characteristic frequency of the outer ring of the rolling bearing

[0160] f o =0.5n(1-d / D p cosθ)f r

[0161] The fault characteristic frequency of the outer ring of the tested bearing is 78.52 Hz.

[0162] Table 1 Test rolling bearing parameters

[0163]

[0164] figure 1 It is the vibration signal and frequency spectrum collected on the test bench. Let the control parameter γ be in space

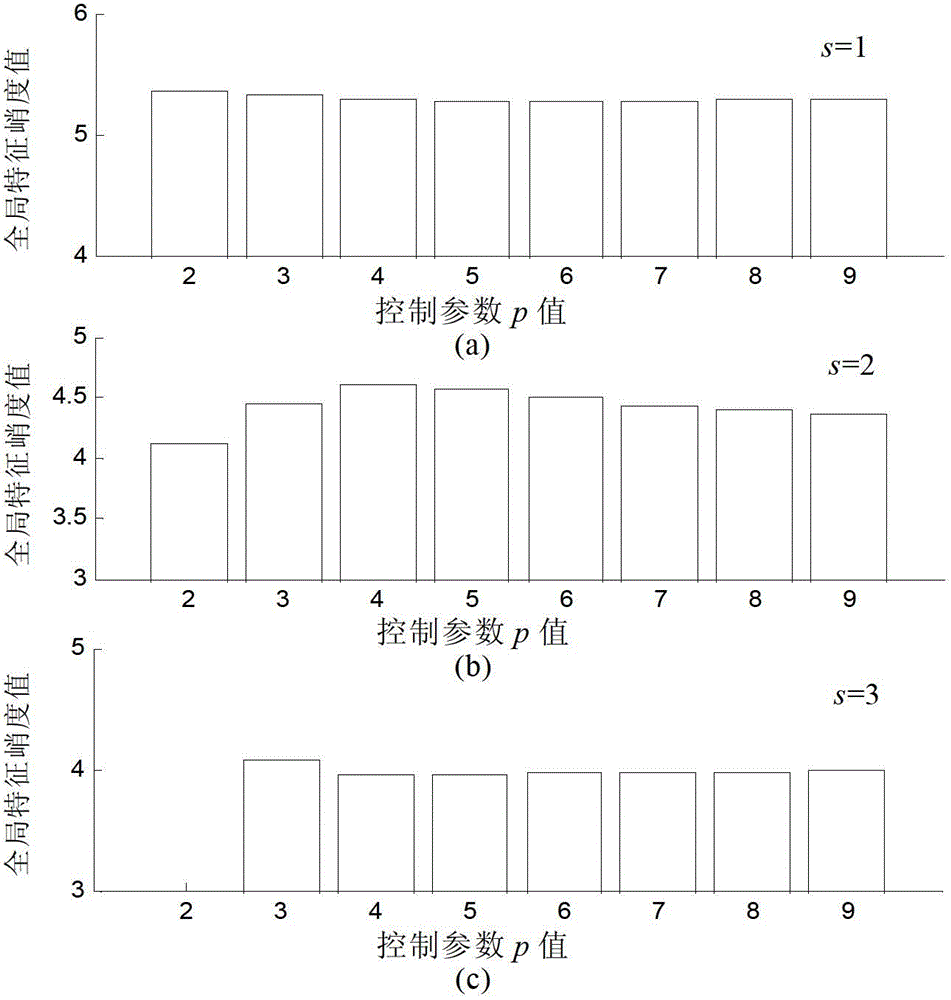

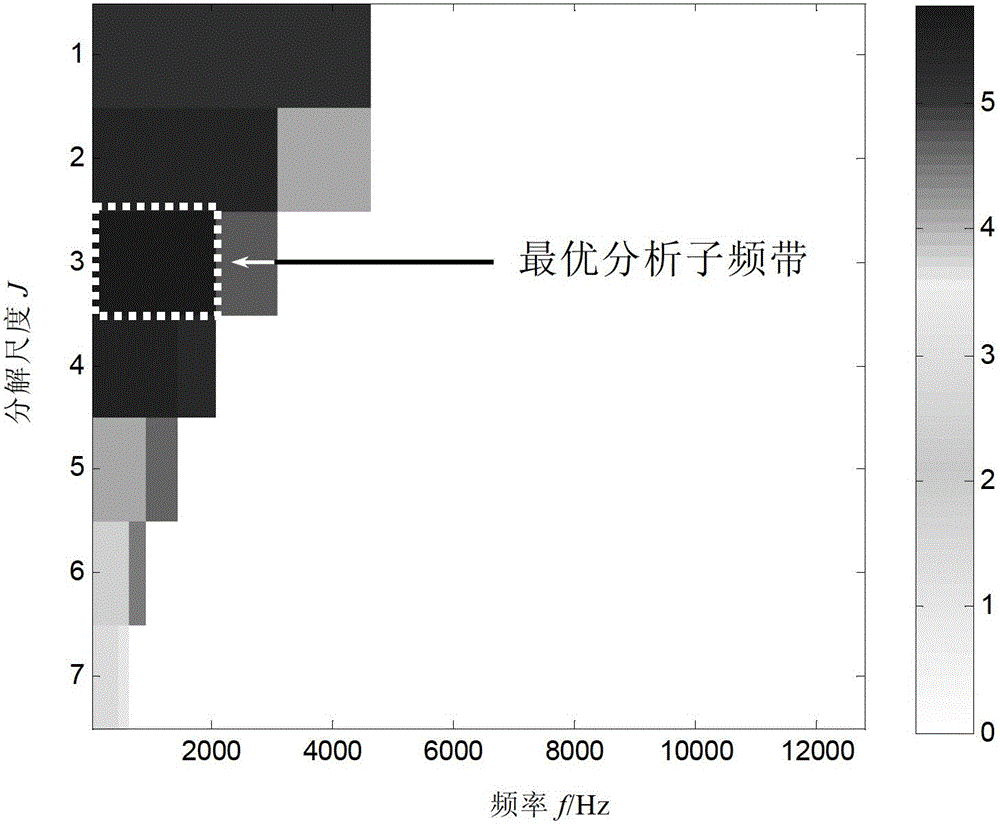

[0165] Γ={(p,q,s)|p,q,s∈Z + ,2≤p≤9,q=p+1,1≤s≤3}

[0166] Take the value in and calculate the global characteristic kur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com