Lithium-ion battery and its cathode plate

A lithium-ion battery, cathode sheet technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries and other directions, can solve the problems of inability to improve the cathode oxidation resistance, reduce the electrolyte contact interface, etc., to broaden the use range, The effect of improving high pressure cycling and high temperature storage performance and reducing the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

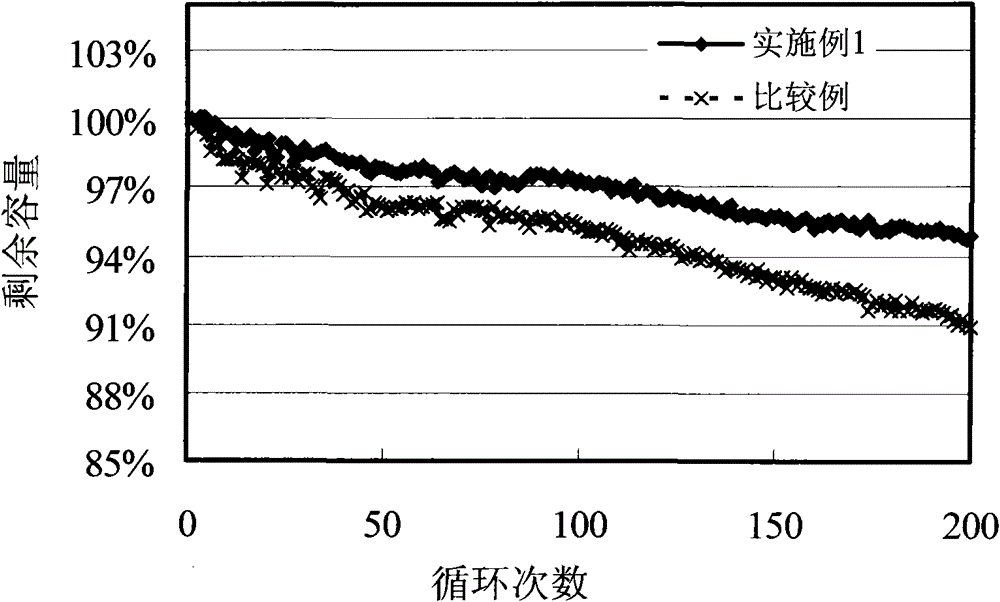

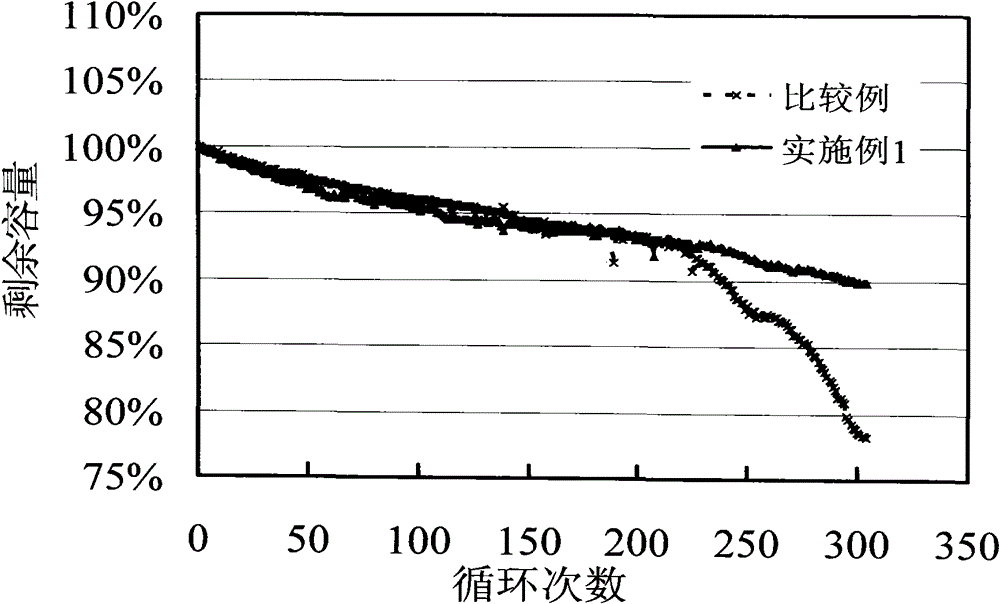

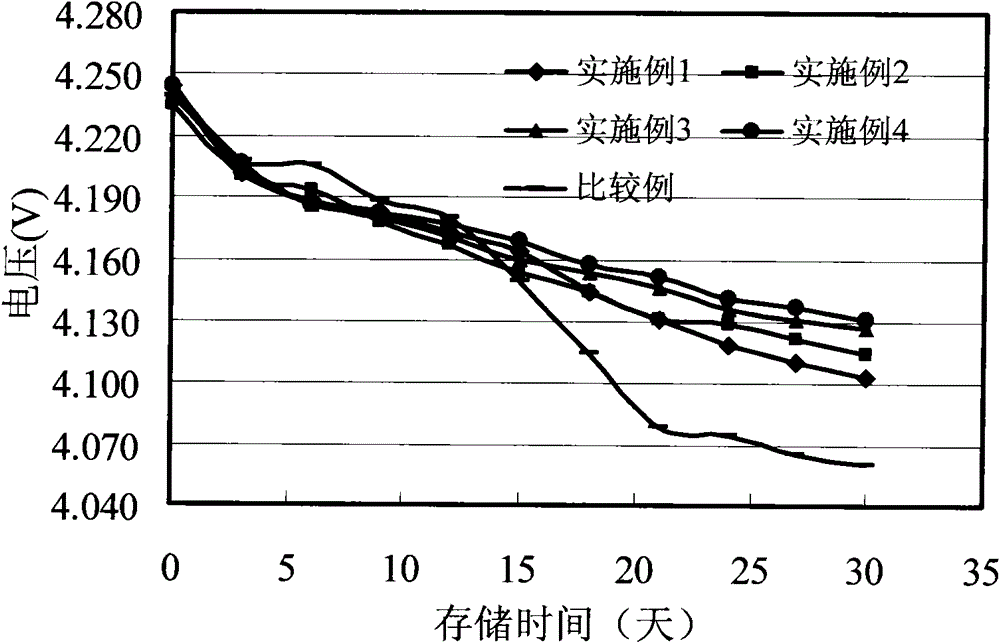

Embodiment 1

[0025] In this embodiment, polymethyl acrylate is used as the cathode polymer additive, and the added mass fraction is 0.1%.

[0026] Cathode electrode sheet preparation: LiCoO 2 (lithium cobaltate), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride), and polymethyl acrylate are added in N,N-dimethylformamide (NMP ) mixed and stirred evenly to obtain a slurry with a certain fluidity, coated on both sides of a 16 μm thick metal aluminum foil, and dried to form a positive electrode sheet with a certain degree of softness. Then, after cold pressing and slitting, the positive electrode lug made of 0.1mm thick aluminum sheet is welded on the aluminum foil to obtain the positive electrode sheet.

[0027] Anode sheet preparation: Graphite, Super-P (conductive carbon black), CMC (water-based binder, carboxymethyl cellulose), and SBR (StyreneButadieneRubber, a kind of rubber) are 95.5:1.5:1.5 according to the mass ratio: 1.5 Add water to mix and stir evenly to obtain a...

Embodiment 2

[0030] In this embodiment, polyethyl acrylate is used as the cathode polymer additive, and the added mass fraction is 0.4%.

[0031] Cathode electrode sheet preparation: LiCoO 2 (Lithium cobaltate), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride), and polyethyl acrylate are added in N,N-dimethylformamide (NMP ) mixed and stirred evenly to obtain a slurry with a certain fluidity, coated on both sides of a 16 μm thick metal aluminum foil, and dried to form a positive electrode sheet with a certain degree of softness. Then, after cold pressing and slitting, the positive electrode lug made of 0.1mm thick aluminum sheet is welded on the aluminum foil to obtain the positive electrode sheet.

[0032] The preparation method of the anode pole piece and the lithium ion battery are the same as in Example 1.

Embodiment 3

[0034] In this embodiment, polyethyl acrylate is used as the cathode polymer additive, and the added mass fraction is 0.6%.

[0035] Cathode electrode sheet preparation: LiCoO 2(Lithium cobalt oxide), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride), and polypropyl acrylate are added in N, N-dimethylformamide (NMP ) mixed and stirred evenly to obtain a slurry with a certain fluidity, coated on both sides of a 16 μm thick metal aluminum foil, and dried to form a positive electrode sheet with a certain degree of softness. Then, after cold pressing and slitting, the positive electrode lug made of 0.1mm thick aluminum sheet is welded on the aluminum foil to obtain the positive electrode sheet.

[0036] The preparation method of the anode pole piece and the lithium ion battery are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com