Mineral processing technology for producing high-quality iron concentrate from iron ore

A technology of iron concentrate and iron ore, which is applied in the field of beneficiation process for the production of high-quality iron concentrate, can solve the problems of high loss of iron concentrate, poor separation effect, and recovery rate of less than 80%, so as to save grinding cost, improving the degree of oxidation, and reducing the effect of grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

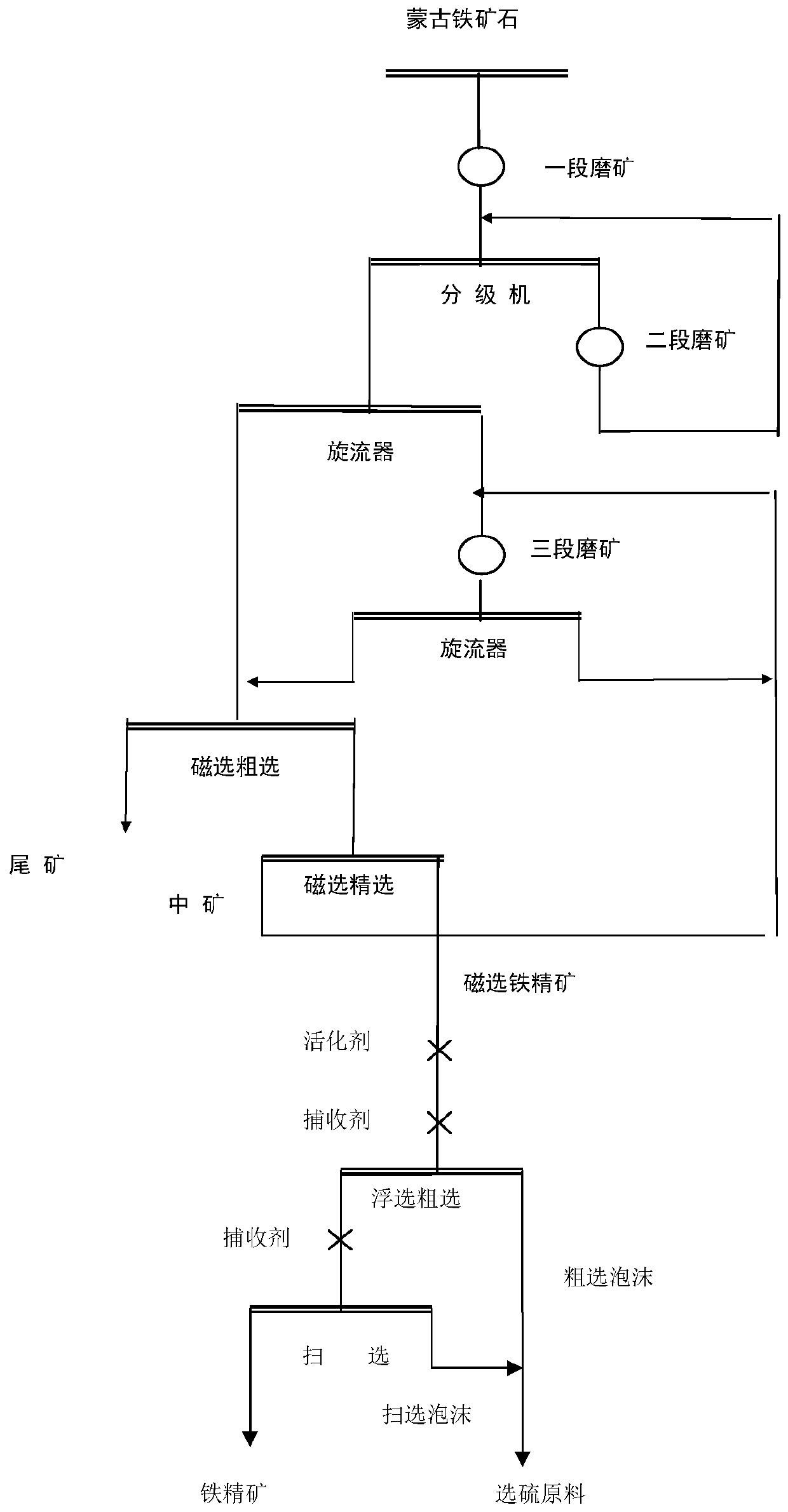

[0021] A beneficiation process for producing high-quality iron concentrate from Mongolian iron ore mainly includes the following parts:

[0022] 1. The Mongolian iron ore is firstly subjected to one-stage grinding (mill model Φ3.2×4.5m), and the first-stage grinding product enters the classifier for a classification operation to obtain a graded sand settling product and a graded overflow product;

[0023] 2. The primary graded grit products obtained by the above steps are subjected to secondary grinding (mill model Φ3.6×4.0m), and the secondary grinding products are returned to the primary classification for inspection and classification; primary grading overflow products enter the cyclone The secondary classification operation is carried out by the device, and the secondary classification grit product and the secondary classification overflow product are obtained;

[0024] 3. The secondary graded grit settling product obtained by the above steps is subjected to three-stage gr...

Embodiment 2

[0031] A beneficiation process for producing high-quality iron concentrate from Mongolian iron ore mainly includes the following parts:

[0032] 1. The Mongolian iron ore is firstly subjected to one-stage grinding (mill model Φ3.2×4.5m), and the first-stage grinding product enters the classifier for a classification operation to obtain a graded sand settling product and a graded overflow product;

[0033] 2. The primary graded grit products obtained by the above steps are subjected to secondary grinding (mill model Φ3.6×4.0m), and the secondary grinding products are returned to primary classification for inspection and classification; primary grading overflow products enter the cyclone The secondary classification operation is carried out by the device, and the secondary classification grit product and the secondary classification overflow product are obtained;

[0034]3. The secondary graded grit settling product obtained by the above steps is subjected to three-stage grindin...

Embodiment 3

[0041] A beneficiation process for producing high-quality iron concentrate from Mongolian iron ore mainly includes the following parts:

[0042] 1. The Mongolian iron ore is firstly subjected to one-stage grinding (mill model Φ3.2×4.5m), and the first-stage grinding product enters the classifier for a classification operation to obtain a graded sand settling product and a graded overflow product;

[0043] 2. The primary graded grit products obtained by the above steps are subjected to secondary grinding (mill model Φ3.6×4.0m), and the secondary grinding products are returned to primary classification for inspection and classification; primary grading overflow products enter the cyclone The secondary classification operation is carried out by the device, and the secondary classification grit product and the secondary classification overflow product are obtained;

[0044] 3. The secondary graded grit settling product obtained by the above steps is subjected to three-stage grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com