Pulsed jet fire-fighting lance

A pulse jet and water gun technology, applied in fire rescue and other directions, can solve problems such as unsatisfactory fire extinguishing effect and spray distance, and achieve the effects of improving water gun performance, improving jet quality and reducing recoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

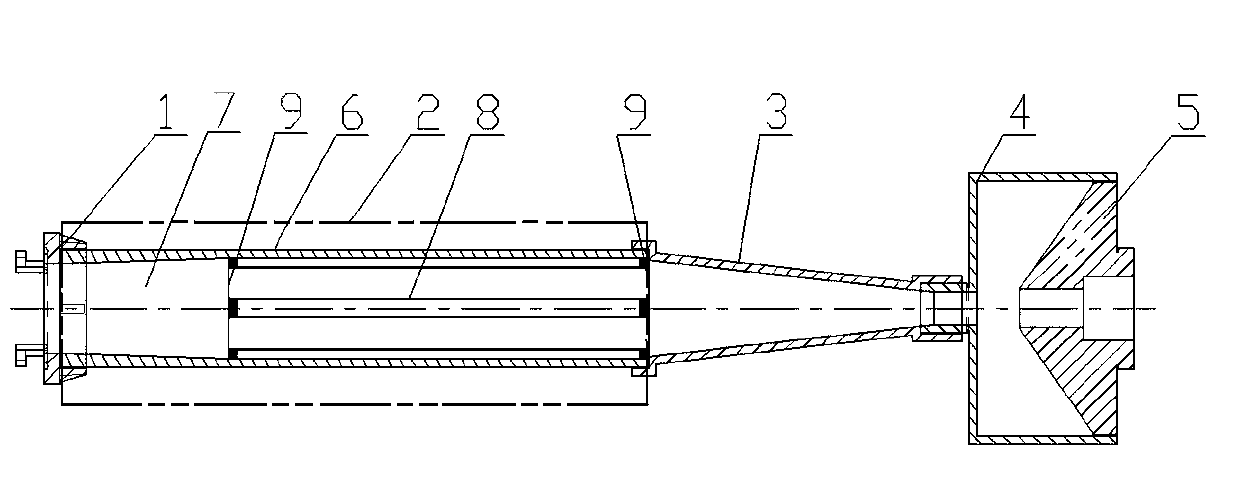

[0011] Such as figure 1 As shown, the connecting piece 1, the rectifying device 2, the conical nozzle 3, the oscillation chamber 4 and the lower nozzle body 5 are sequentially installed on the same center line. Connector 1 adopts the common interface of fire hose, and the size of the interface of connector 1 remains unchanged. The diameter of the through hole of connector 1 is 56 mm. The rectification device 2 includes a pipe body 6 with an inner diameter of 60 mm. The pipe body 6 is divided into a stabilizing section and a rectifier. Between the connecting piece 1 and the rectifier is a stabilizing section 7 whose length is 1.5 to 2.5 times the diameter of the main pipe; Cone connection is adopted between them (cone angle is 1.7°); the rectifier adopts honeycomb type rectifier, including 4 to 10 steel pipes with a diameter of 10 to 25mm, the wall thickness of the steel pipes is 0.4 to 1mm, and the two ends of the steel pipes 8 are welded with the fixed plate 9, It should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com