Patents

Literature

34results about How to "Improve jet quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

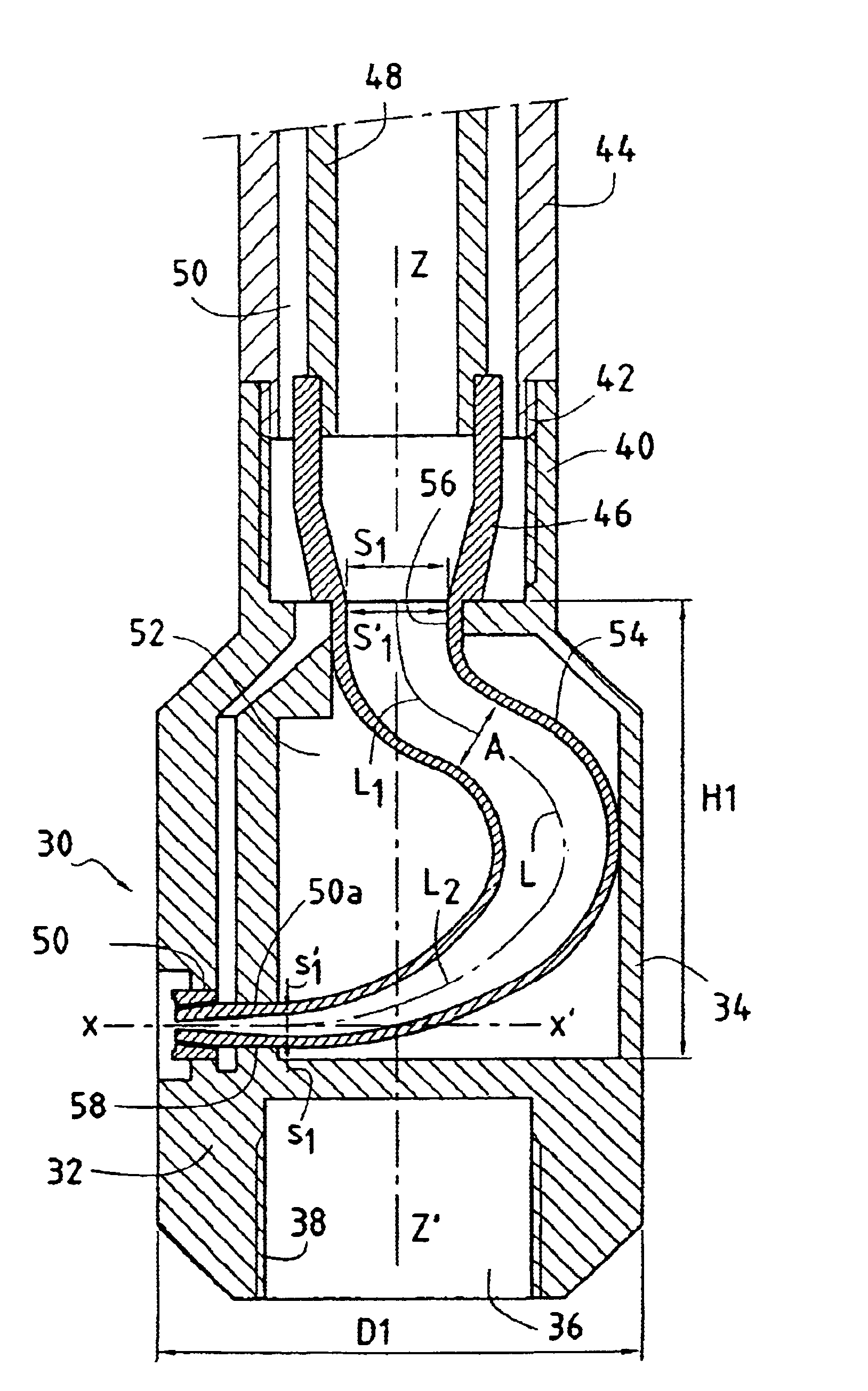

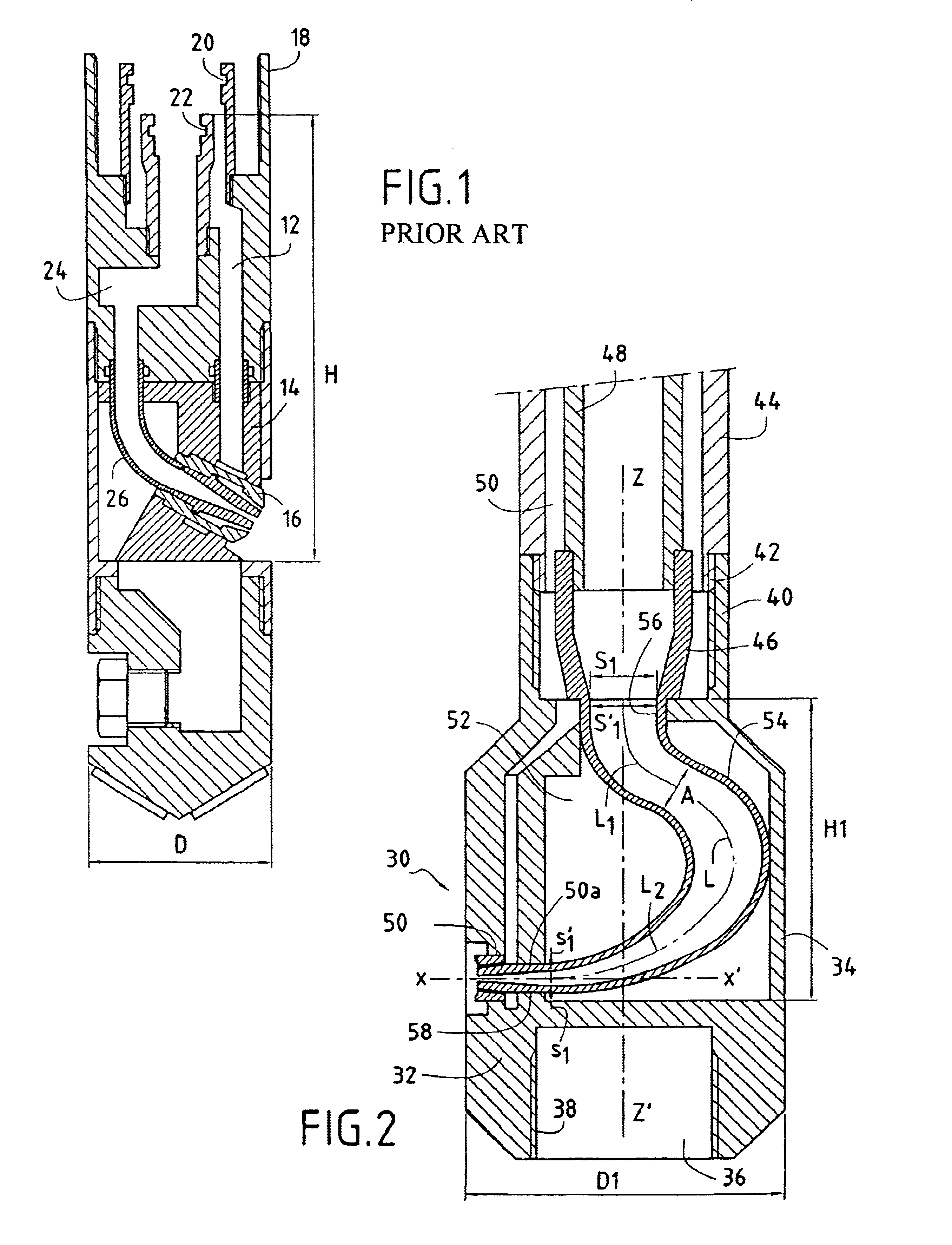

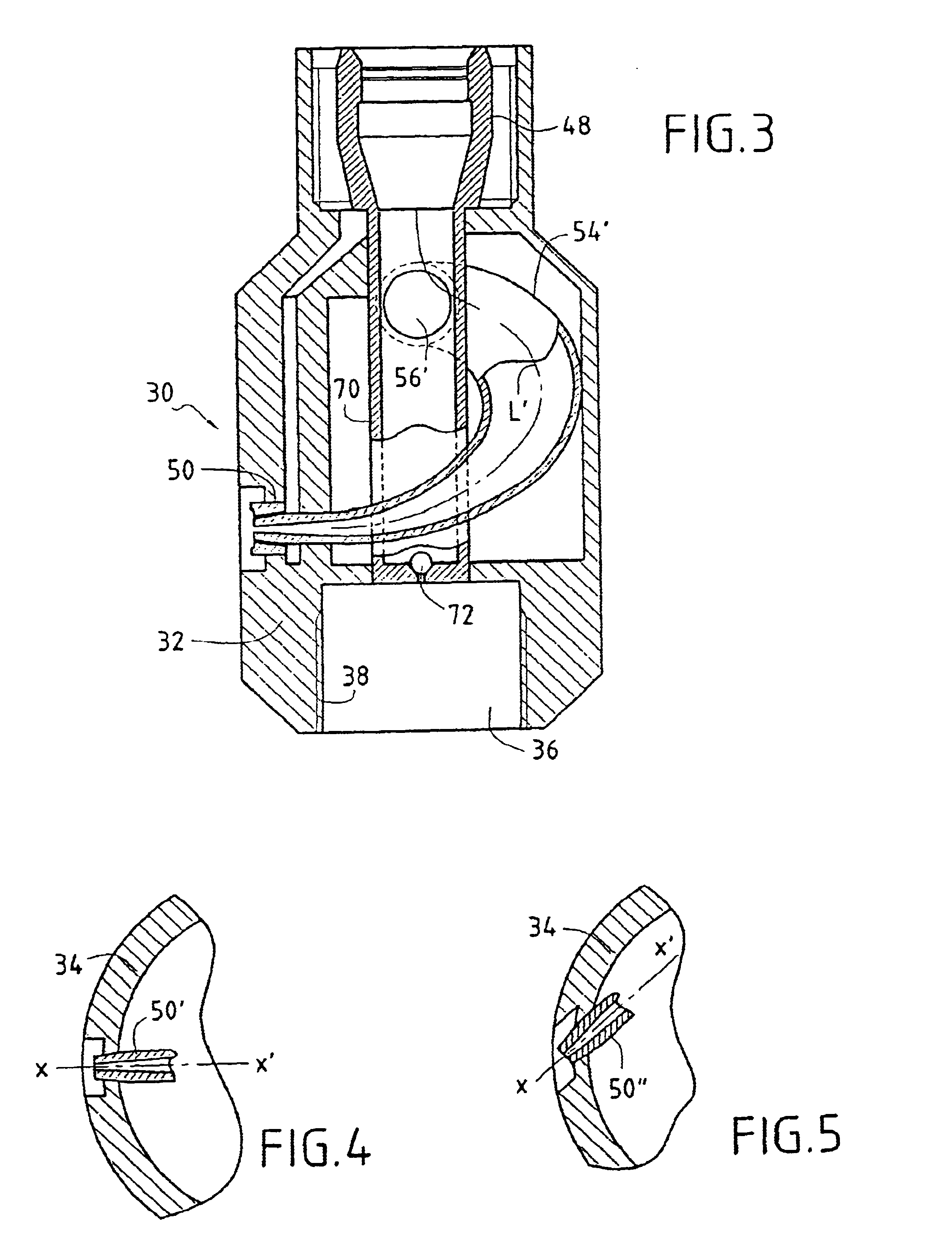

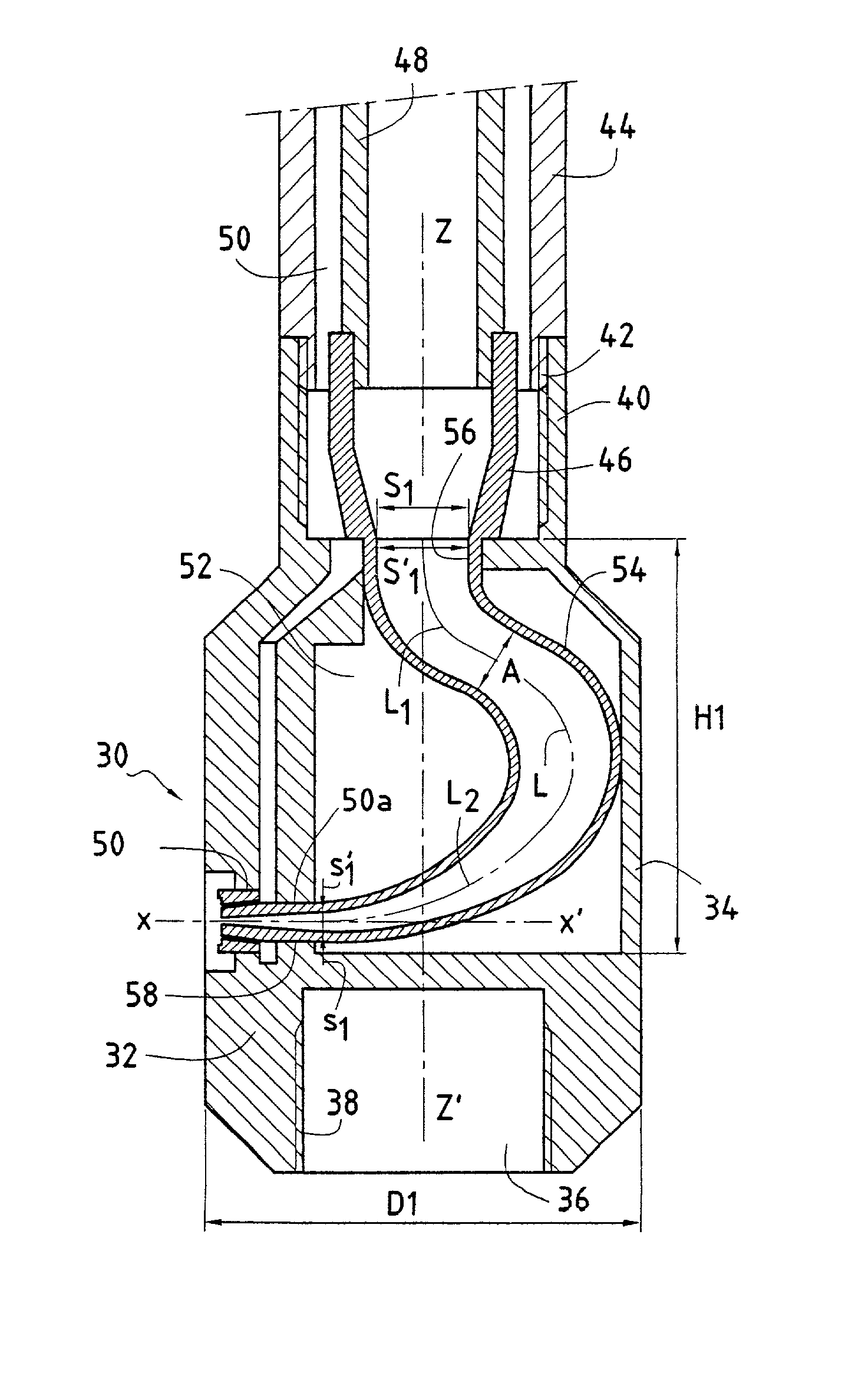

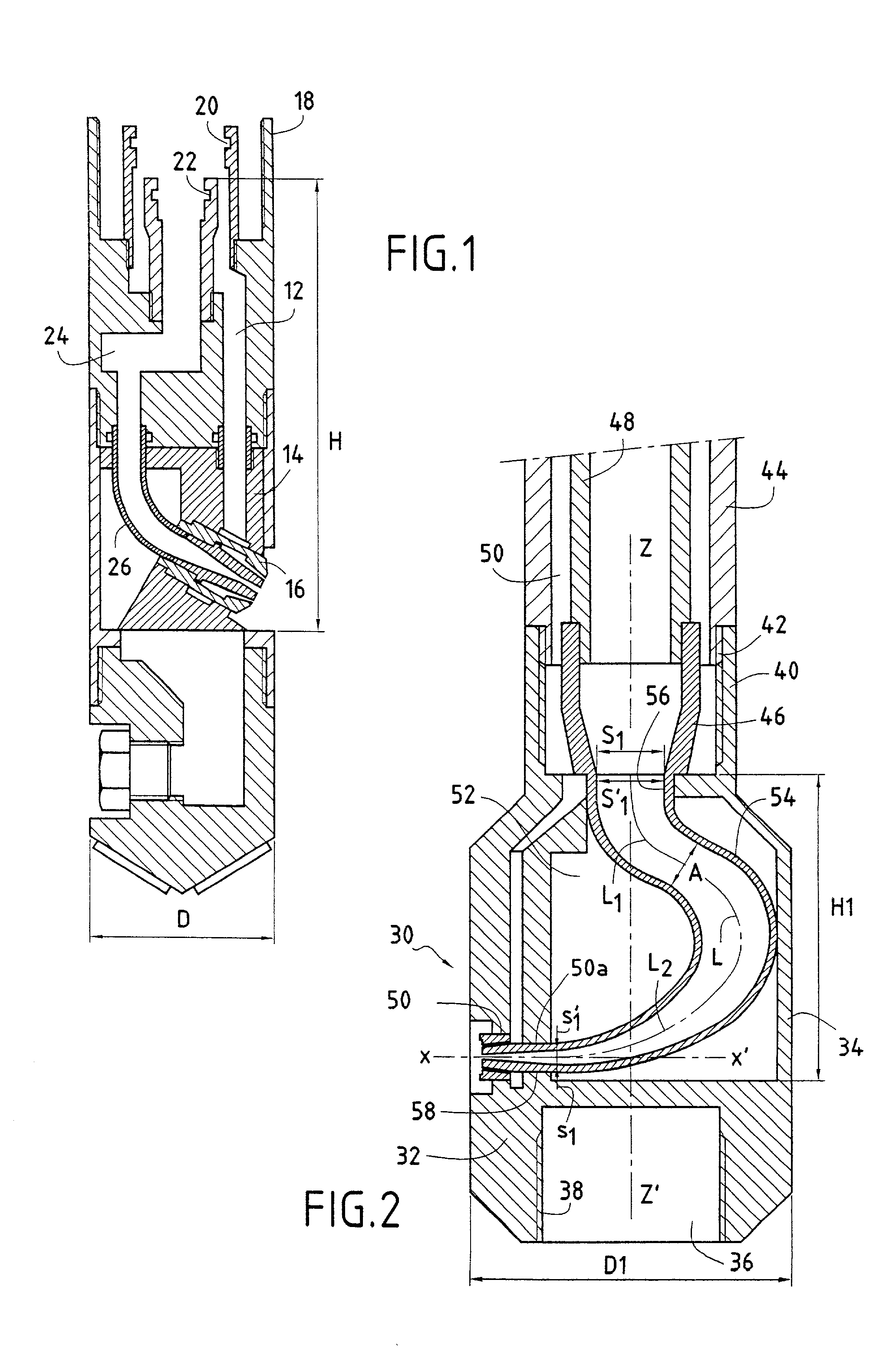

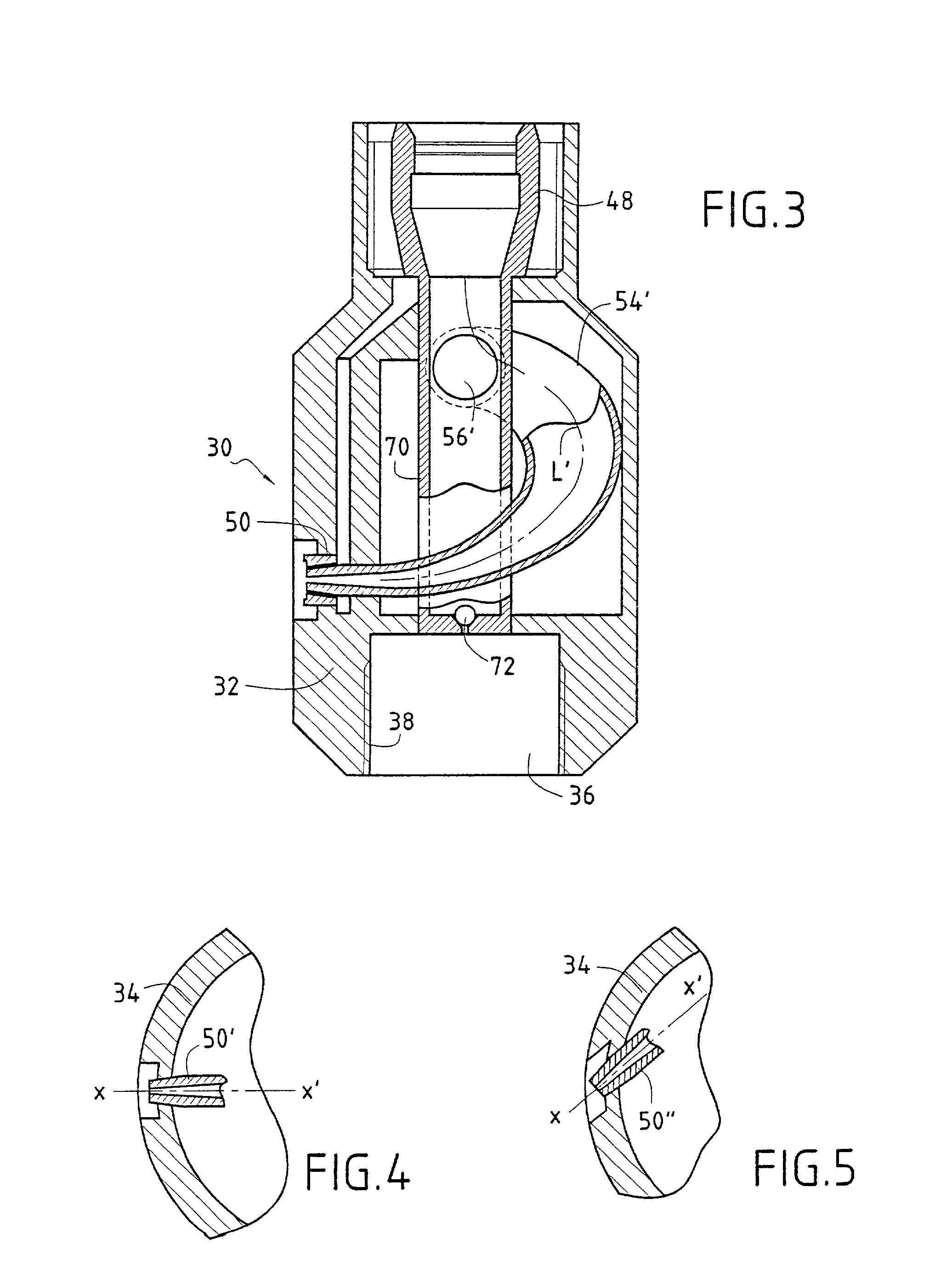

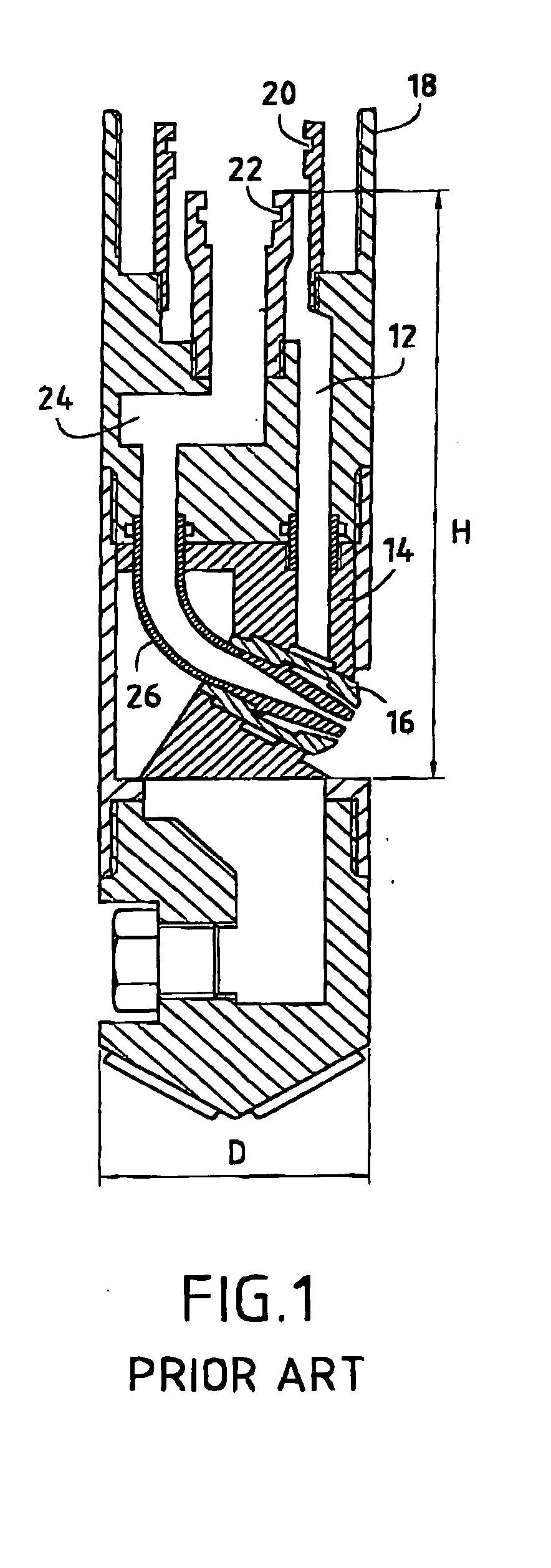

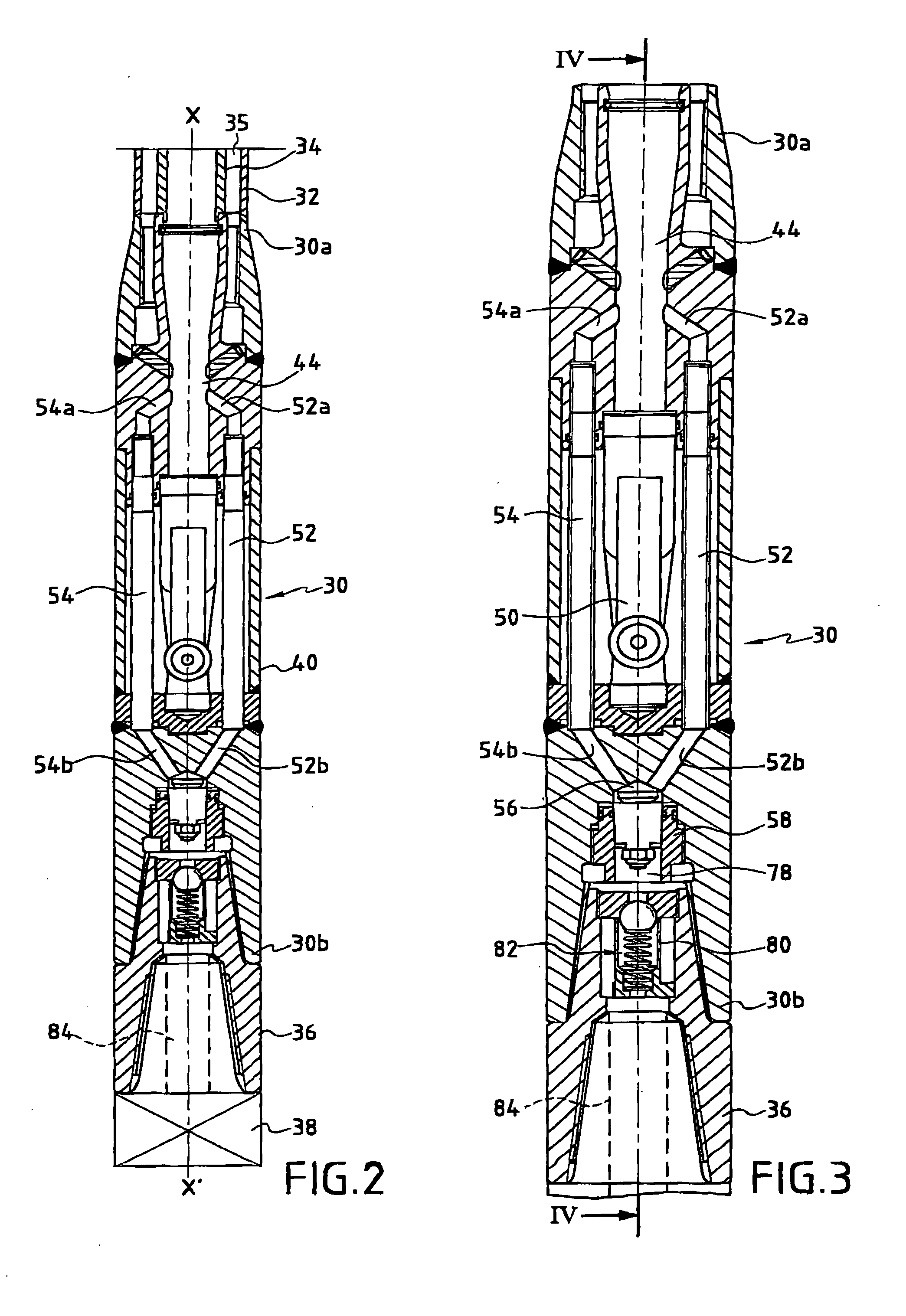

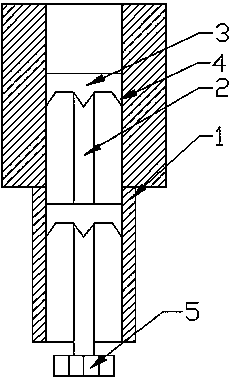

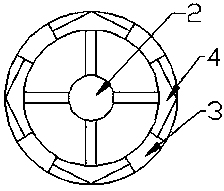

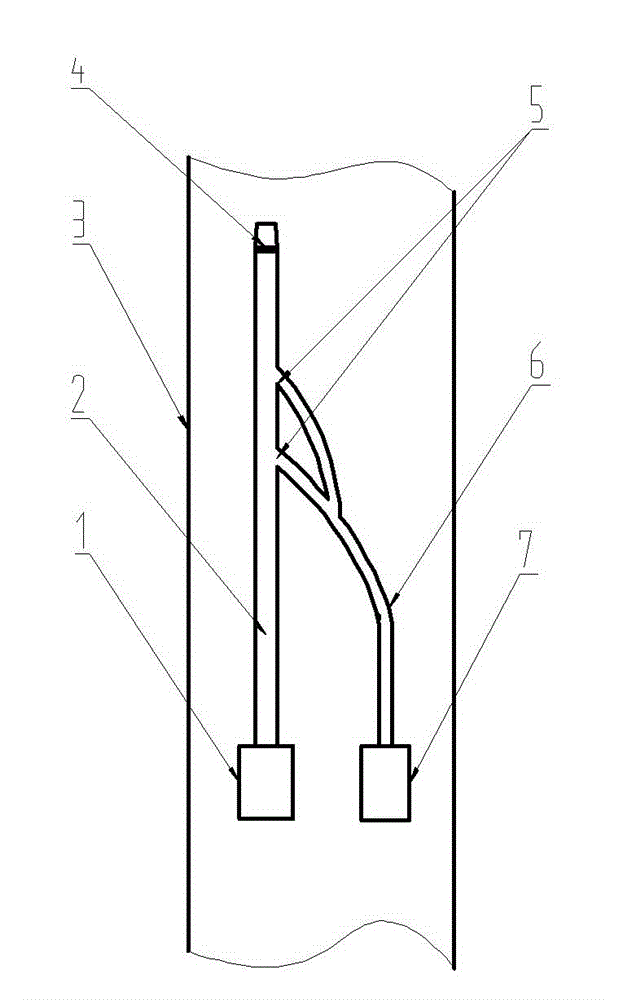

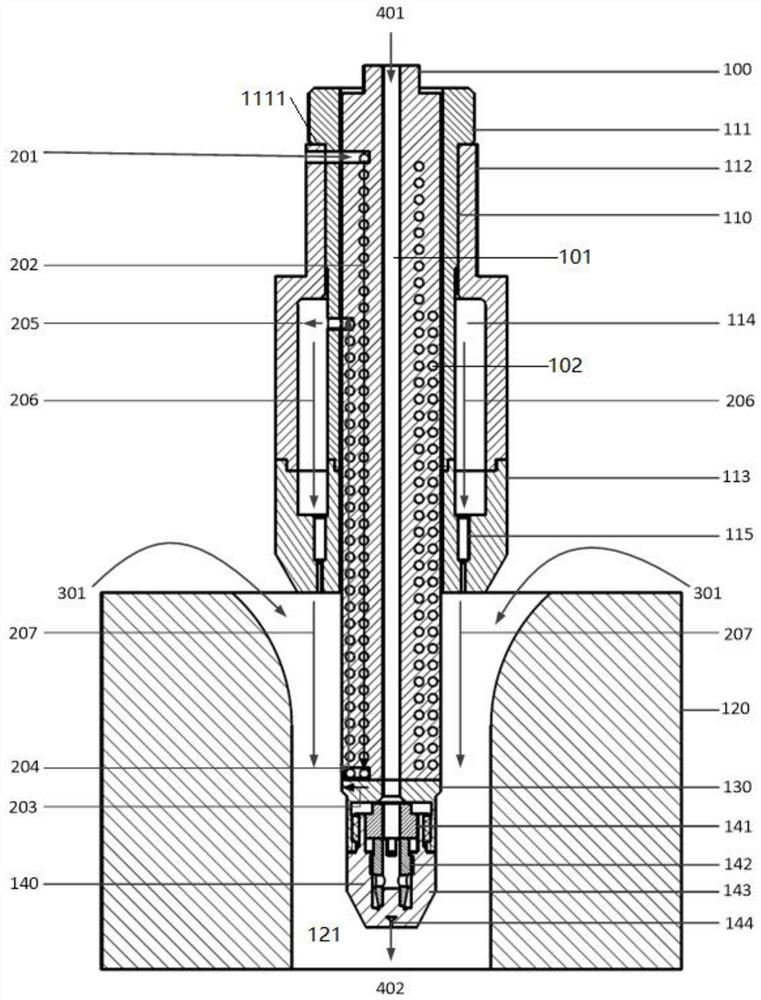

Head for injecting liquid under pressure to excavate the ground

InactiveUS6648084B2Improve jet qualityMinimize disturbanceLiquid/gas jet drillingFluid removalNozzleDrill string

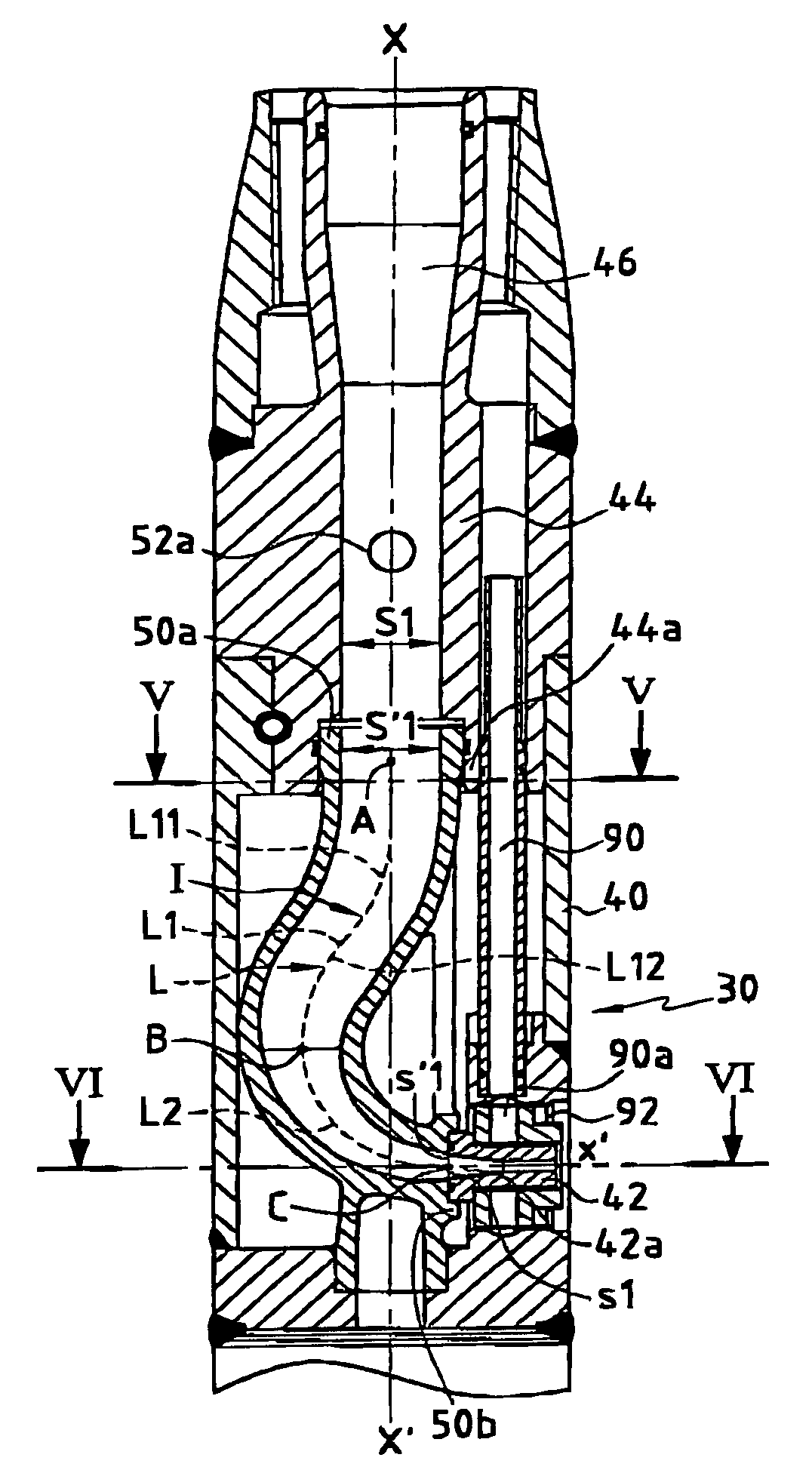

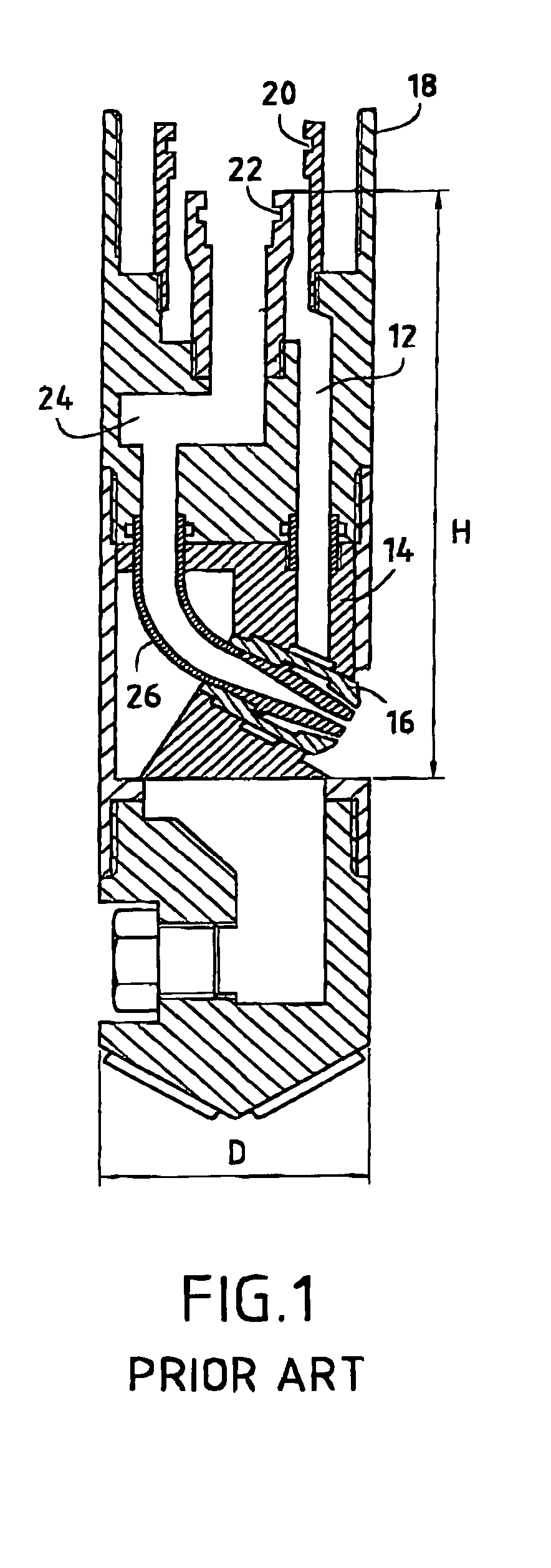

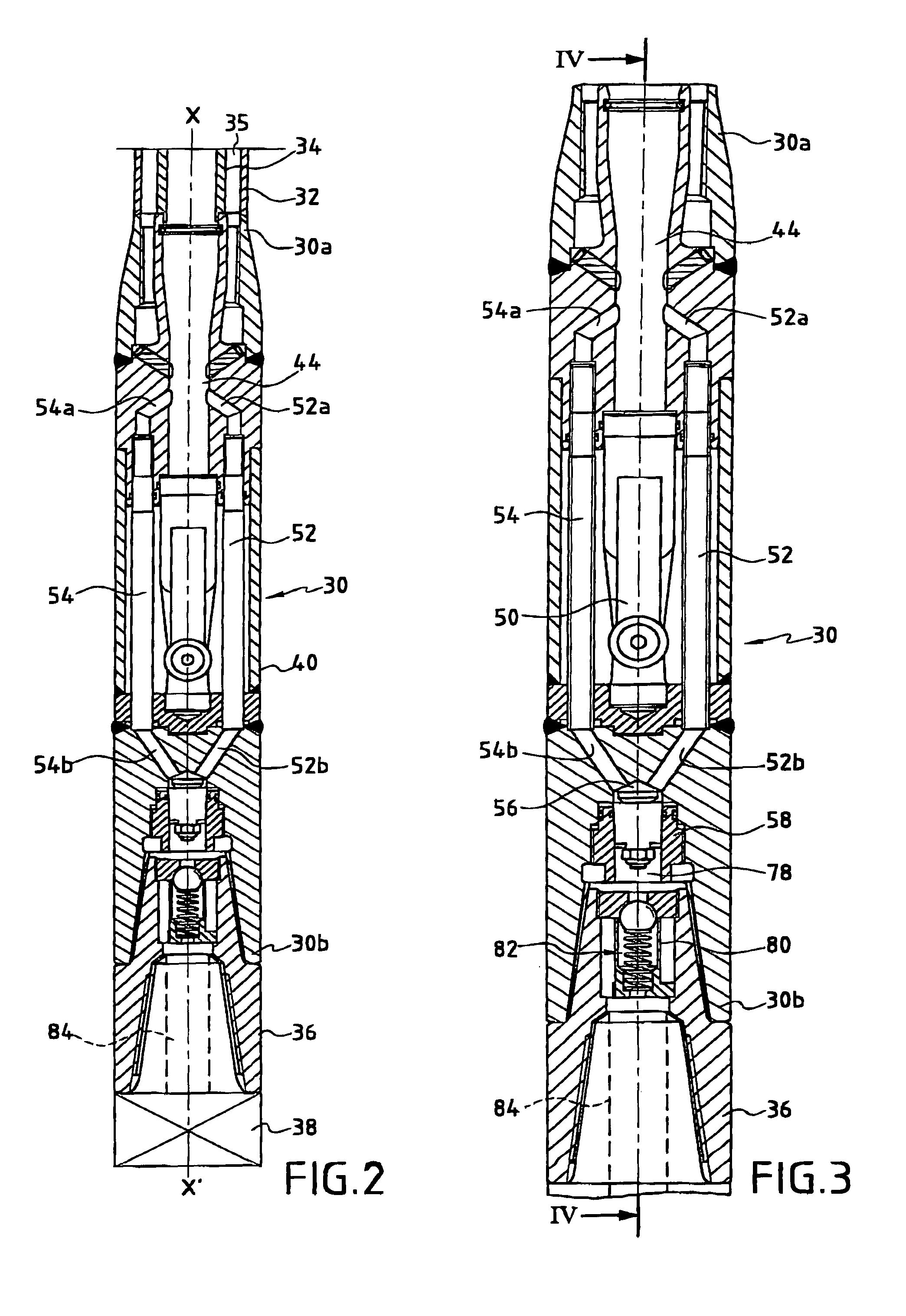

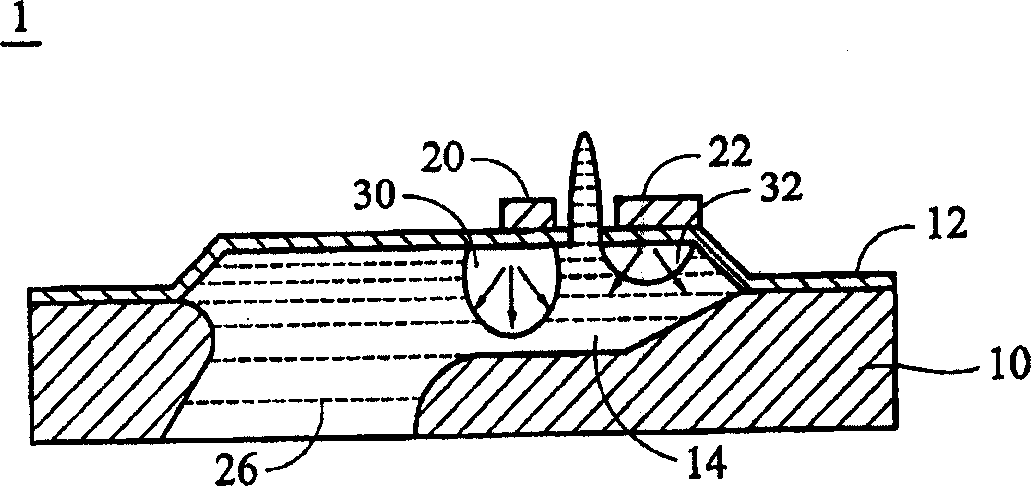

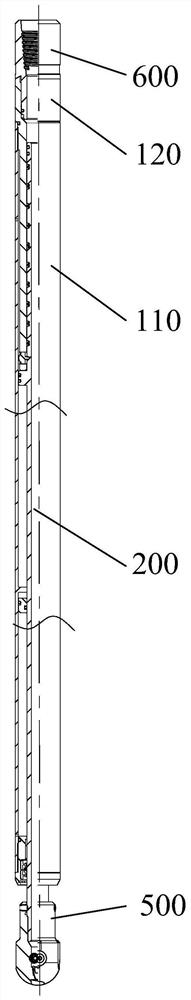

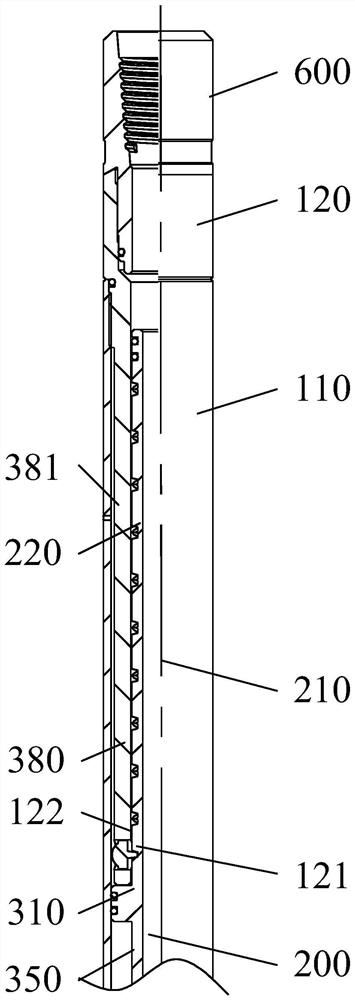

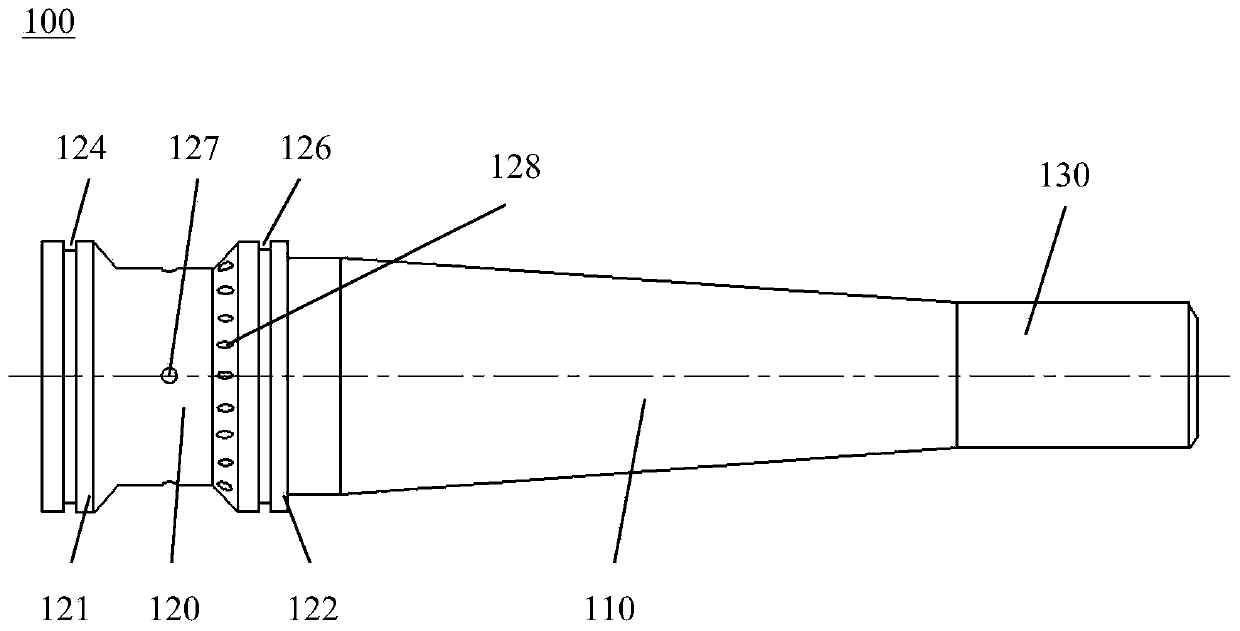

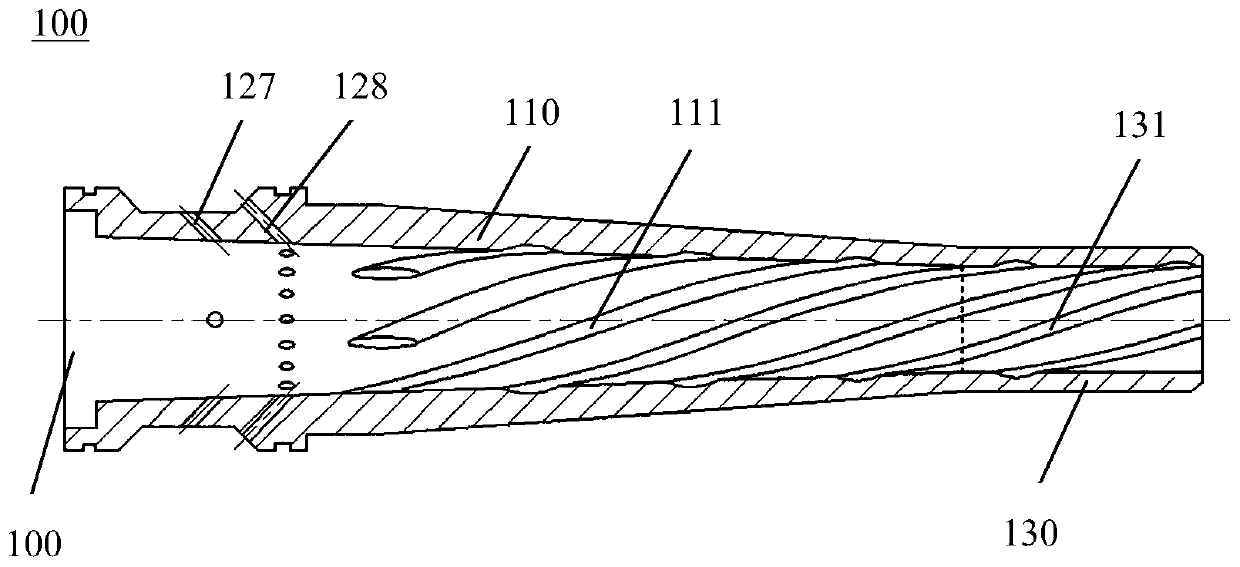

The invention provides a head for injecting a liquid under pressure from a borehole to break up the soil, said head being mounted at the end of a drill string including a liquid feed for feeding a liquid under pressure. The head comprises a body and an outside wall, the body having at least one injection nozzle mounted therein, the nozzle having an inlet diameter equal to d and presenting an axis (x-x'), the body also having a tube. The tube presents a mean line having a first end connected to the bottom end of the liquid feed and having a second end connected to the nozzle tangentially to the axis (x-x'). The mean line is defined by at least one curved portion presenting a radius of curvature that varies continuously. The right section of the tube decreases regularly over at least half of its length from its first end to its second end.

Owner:CIE DU SOL

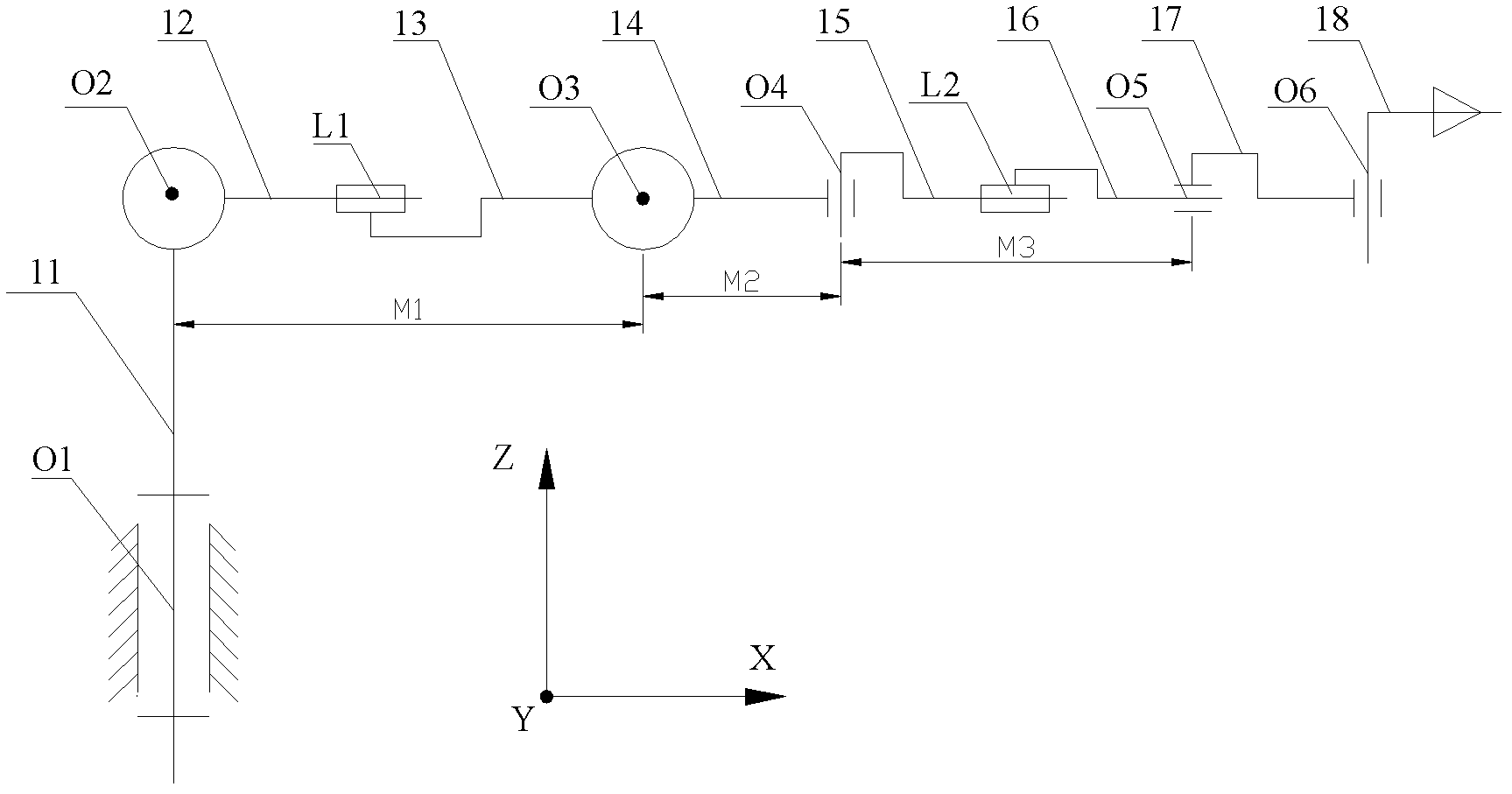

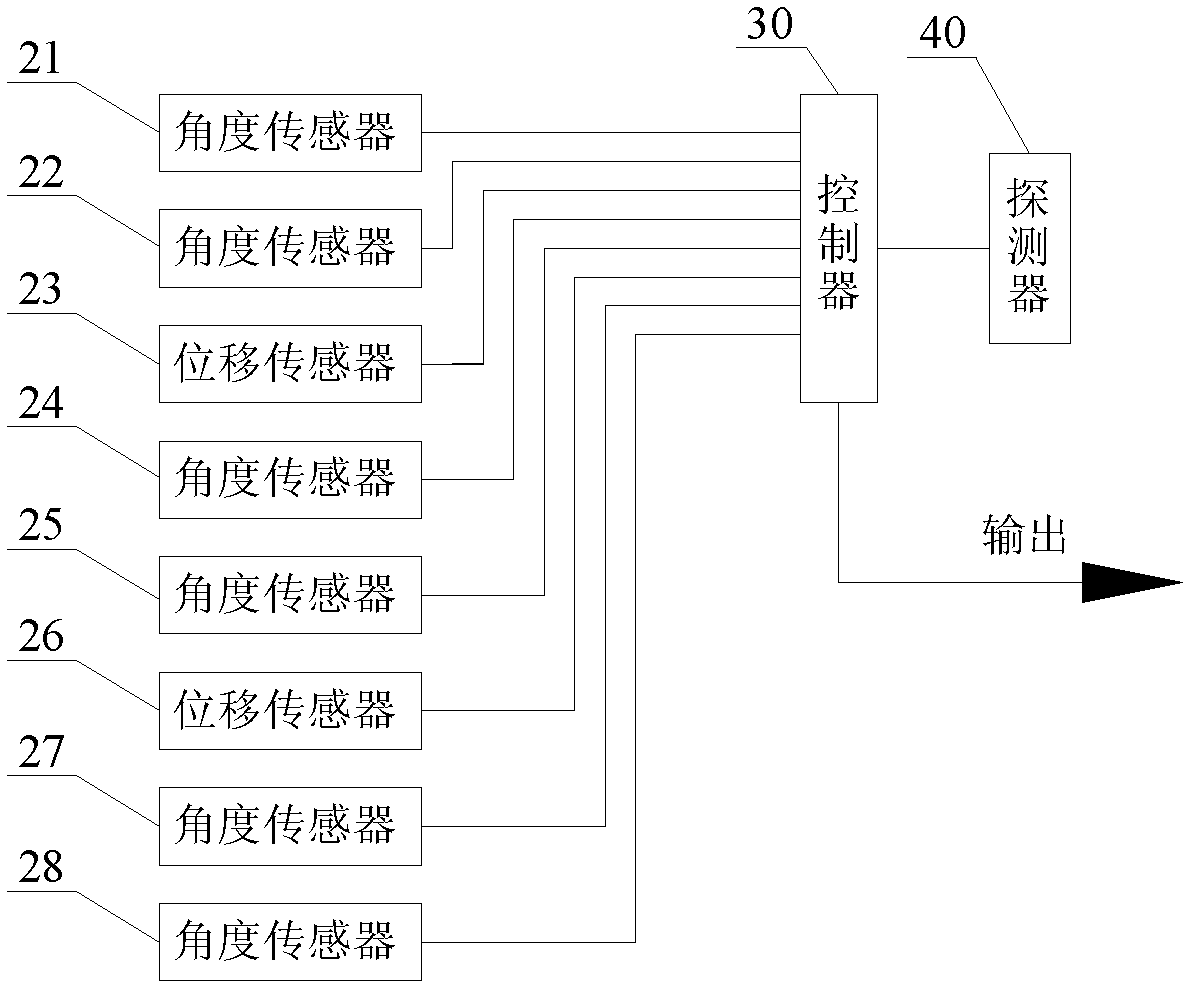

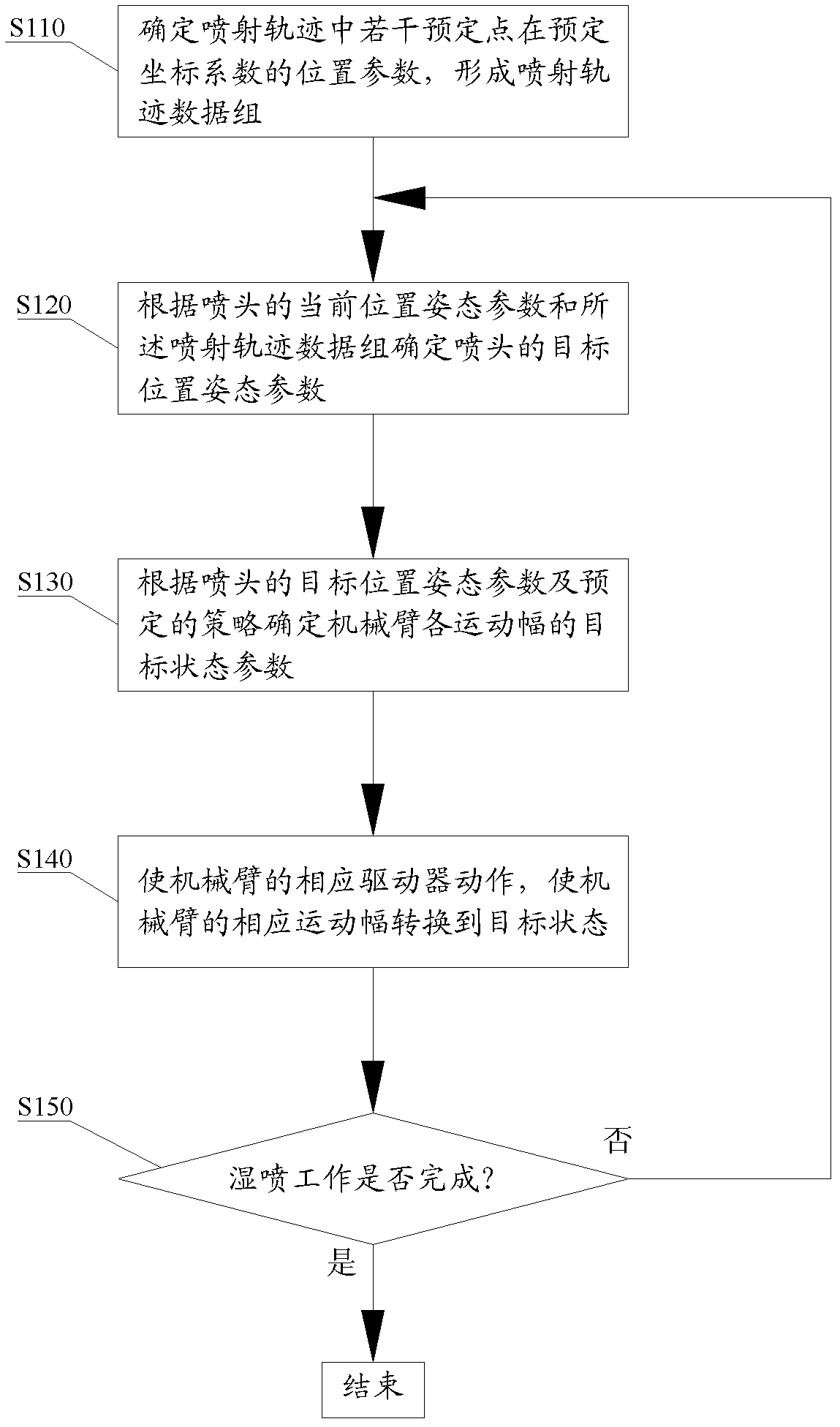

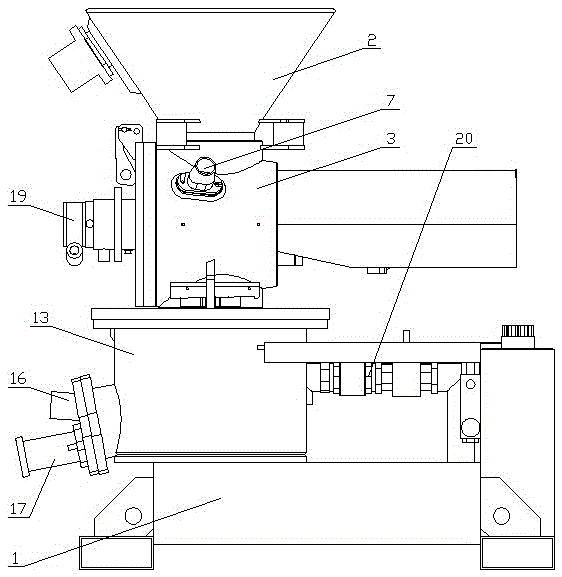

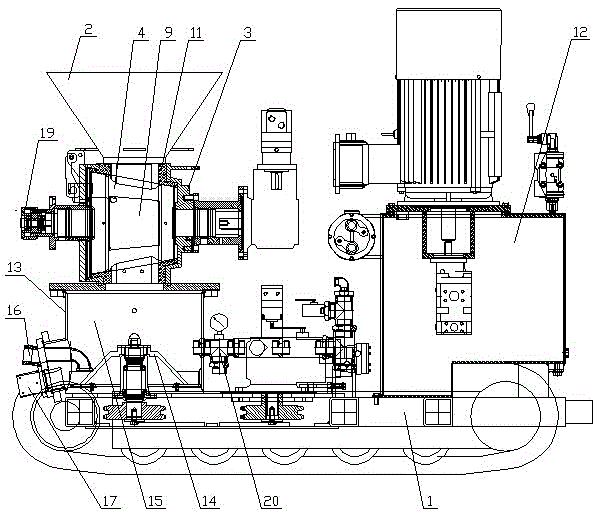

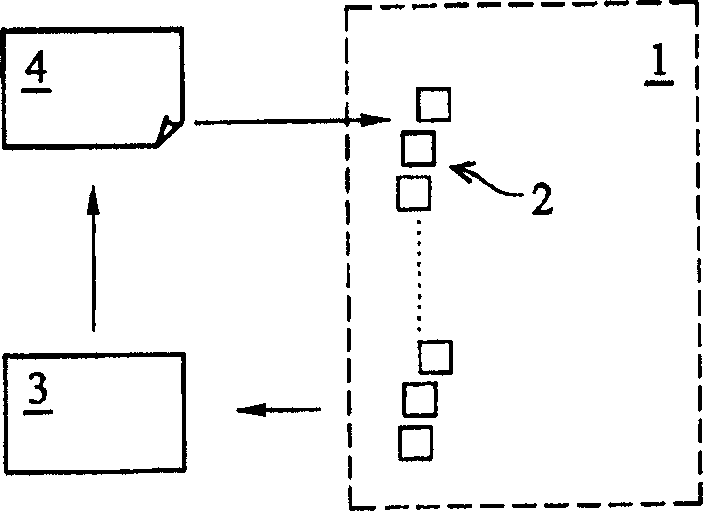

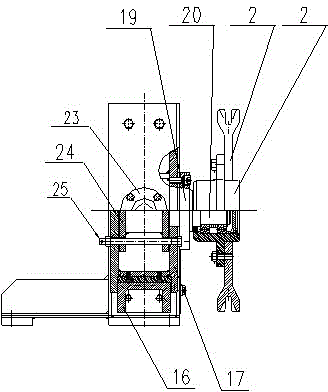

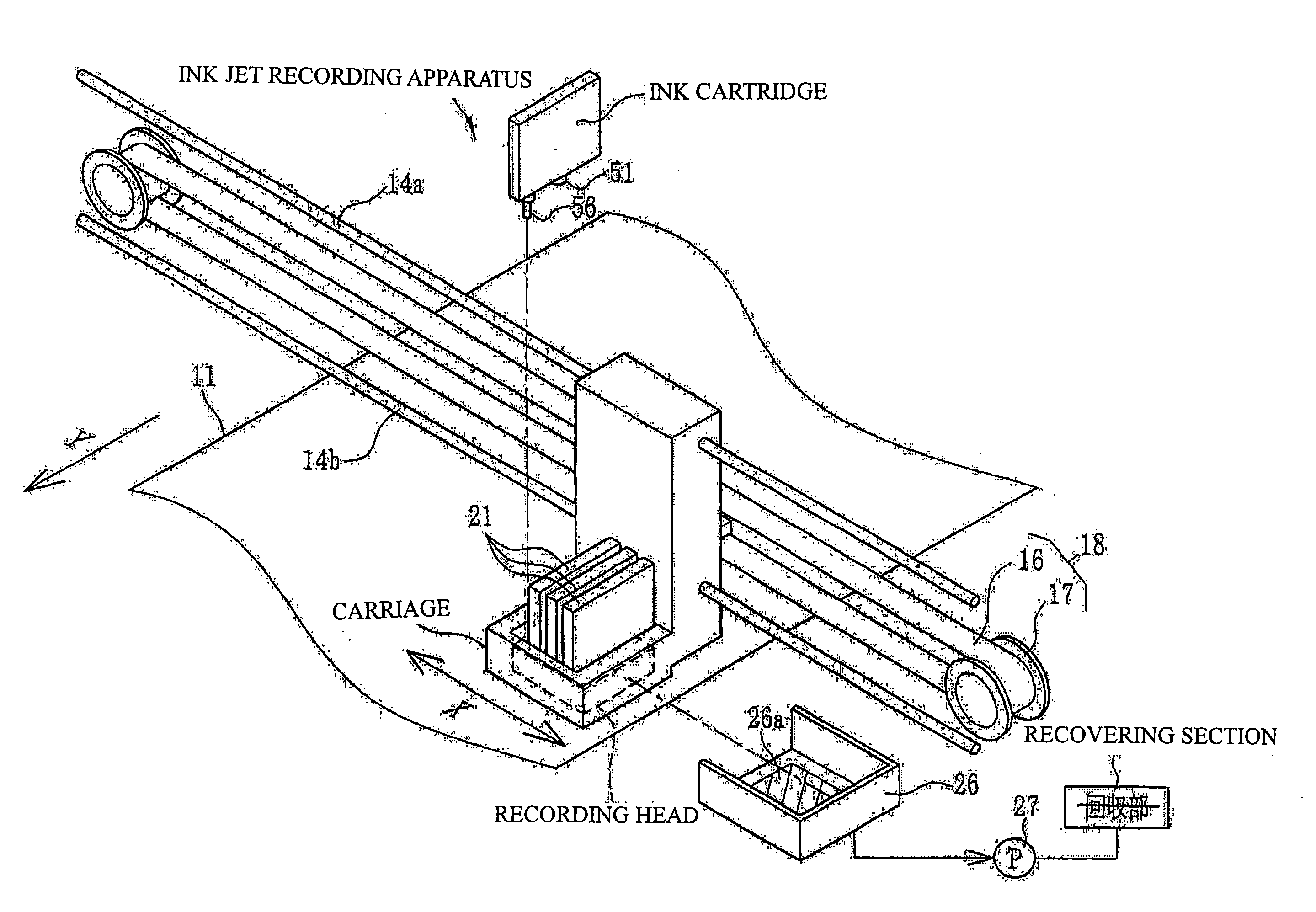

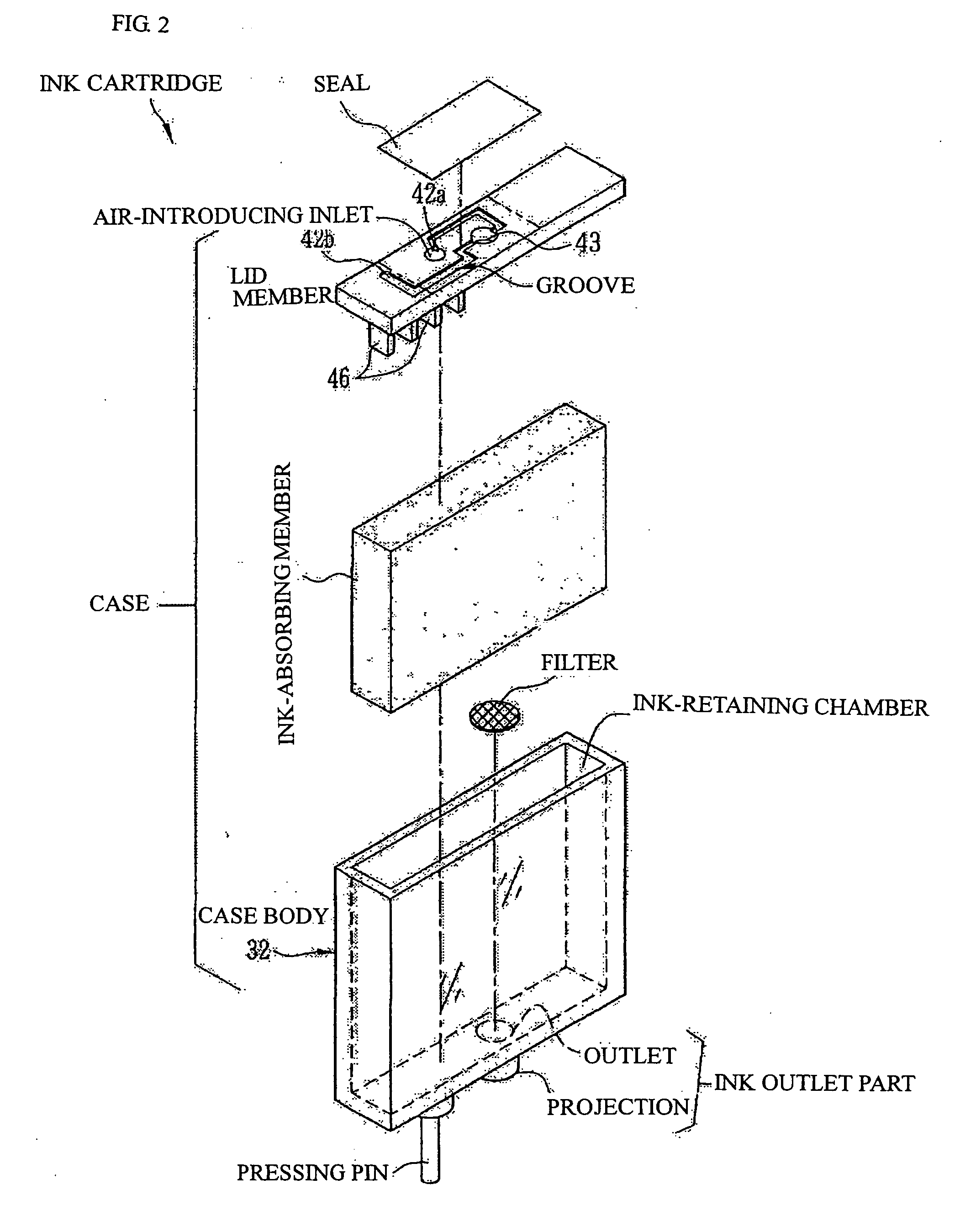

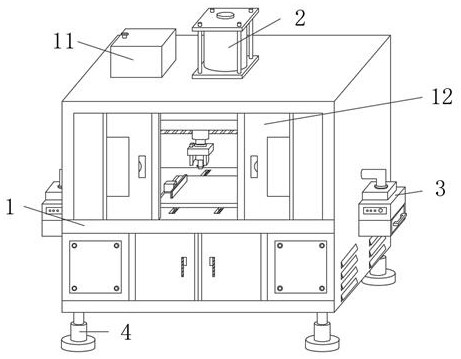

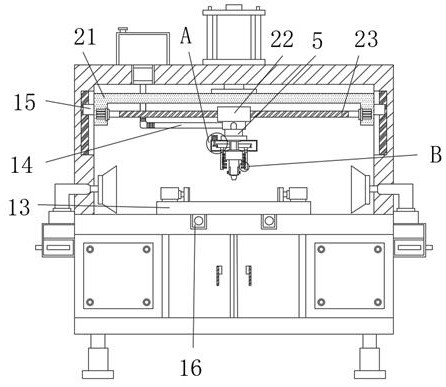

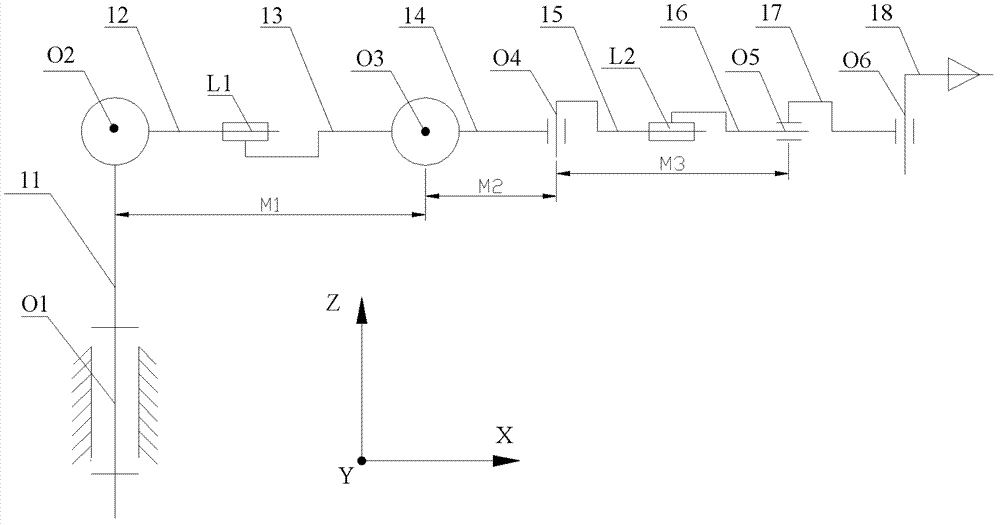

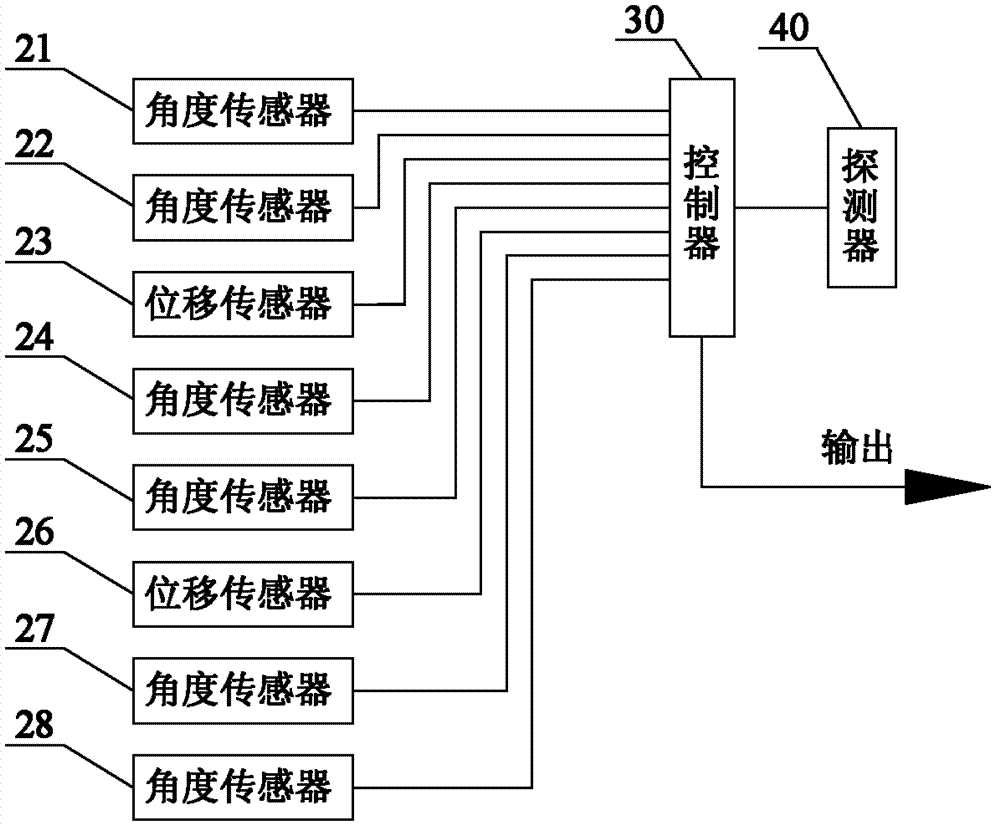

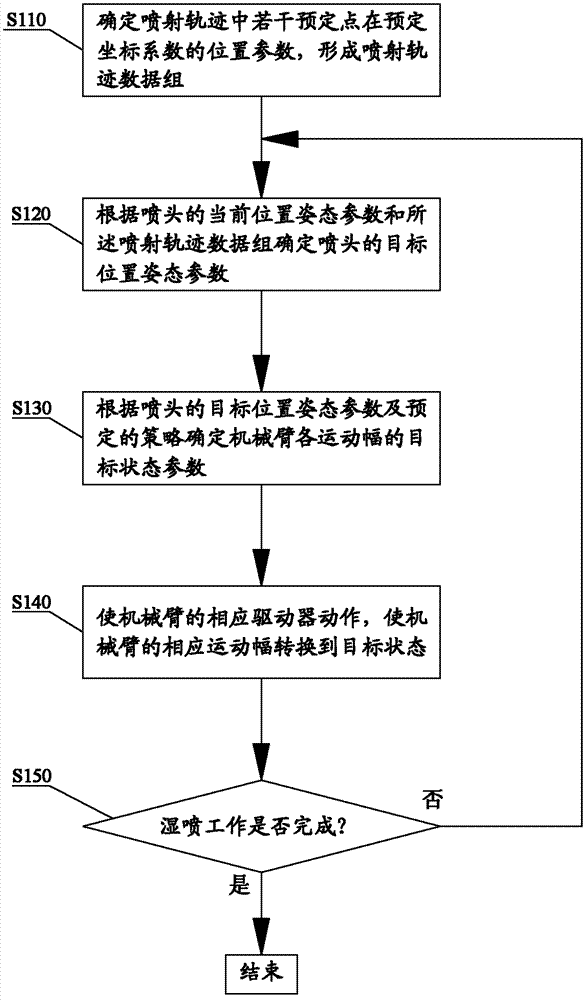

Injection machine and mechanical arm, injection control method and injection control device thereof

ActiveCN102505853AEasy to controlJet trajectory optimizationUnderground chambersBuilding material handlingControl signalState parameter

The invention discloses an injection machine and a mechanical arm, an injection control device and an injection control method thereof. In the injection control device of the injection machine, status sensors detect current status parameters of corresponding motion amplitudes of the mechanical arm, a controller determines current position and orientation parameters of nozzles according to the current status parameters of the motion amplitudes, and then the target position and orientation parameters of the nozzles are determined, the target status parameters of different motion amplitudes are determined, and preset control signals are formed according to the target status parameters of the motion amplitudes and the current status parameters of the motion amplitudes of the mechanical arm, and are sent to corresponding drivers of the mechanical arm finally. According to the target position and orientation parameters of the nozzles, the injection control device changes status parameters of the motion amplitudes of the mechanical arm, drives the nozzles to reach the preset target positions along the preset tracks so as to switch into the preset orientations, thereby realizing accurate control to injection angle and distance and reducing independence to personal factors of operators.

Owner:SANY AUTOMOBILE MFG CO LTD

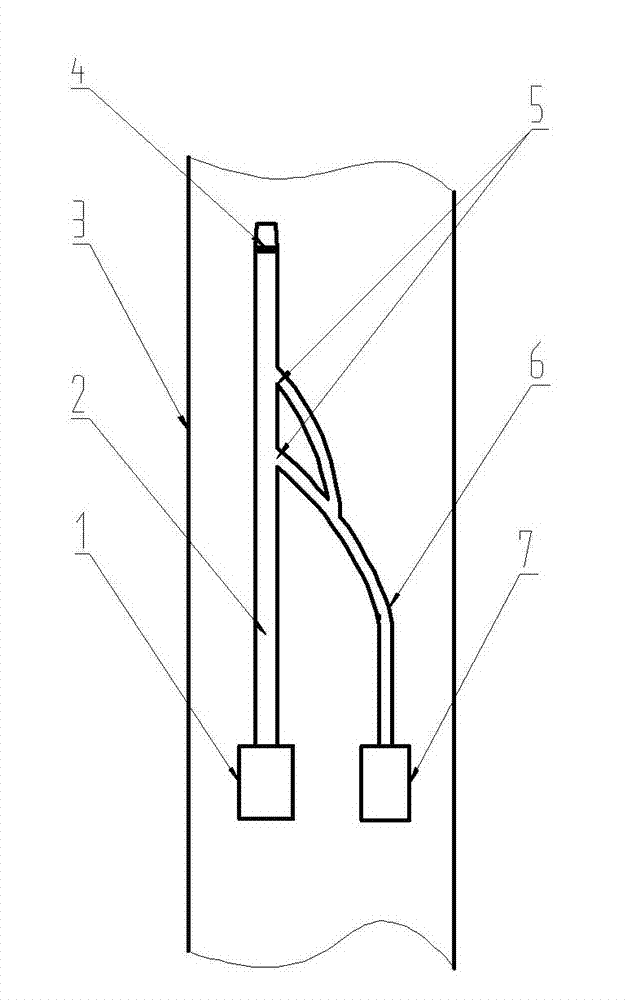

Mining method for jetting concrete in wet type

ActiveCN102733823AReduce cloggingAvoid restrictionsUnderground chambersTunnel liningShotcreteCement slurry

The invention relates to a mining method for jetting concrete in a wet type; a method comprises the following steps: preparing cement slurry; stirring gravel mixing material; starting air source to input high pressure air to a gravel mixing material transport pipeline in a jetting procedure; and inputting the cement slurry to a cement slurry transport pipeline through transport equipment; after jetting the cement slurry by a nozzle, adding the gravel mixing material to a jetting machine; under the action of the high pressure air, mixing and stirring the cement slurry and the gravel mixing material; finally, jetting the concrete from the nozzle. According to the invention, the method depends on current jetting equipment; a transport distance (larger than or equal to 60m) of jet concrete is can be increased greatly on a condition of ensuring invariable wet-type concrete jetting advantages; simultaneously, the method effectively avoids problems that large-scale stirring is used hardly and concrete transport equipment is limited under a coal well; production efficiency and jetting quality are improved greatly; in addition, powder dust concentration near the jetting machine is less than or equal to 10mg / m<3>.

Owner:河南省煤科院科明机电设备有限公司

Head for injecting liquid under pressure to excavate the ground

InactiveUS20020108752A1Improve jet qualityMinimize disturbanceCleaning apparatusLiquid/gas jet drillingNozzleDrill string

Owner:CIE DU SOL

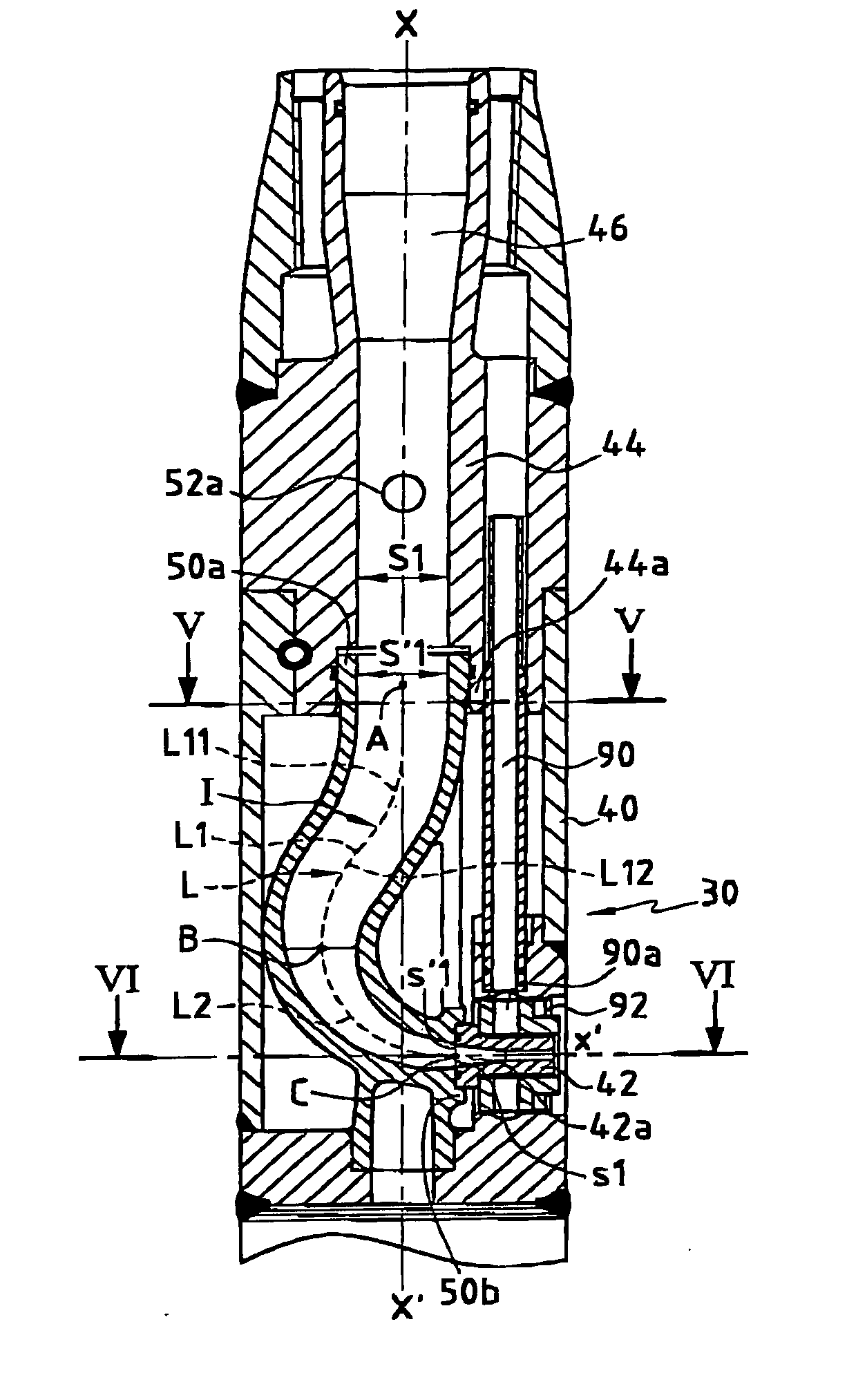

Head for injecting a fluid under pressure to break up ground from a borehole

InactiveUS20050077041A1Minimize disturbanceShorten the timeDrill bitsDrilling rodsEngineeringDrill bit

The present invention provides a head for injecting a fluid under pressure for breaking up the ground from a borehole and mounted at the end of a string of rods. The body of the drilling head has a bottom wall for mounting a mechanical drilling tool having a feed pipe, at least one injection nozzle, and duct-forming means for connecting the feed pipe with liquid at the inlet of said nozzle, the duct-forming means presenting a mean line having a radius of curvature that varies continuously, the right section of said duct-forming means decreasing regularly over at least half its length from its first end towards its second end. The injection head further comprises at least one pipe for feeding said mechanical tool, said pipe being connected at a first end to said duct-forming means and at a second end to a chamber disposed at the bottom end of said injection head and fitted with a controllable shutter member interposed between said chamber and the pipe for feeding said mechanical tool.

Owner:CIE DU SOL

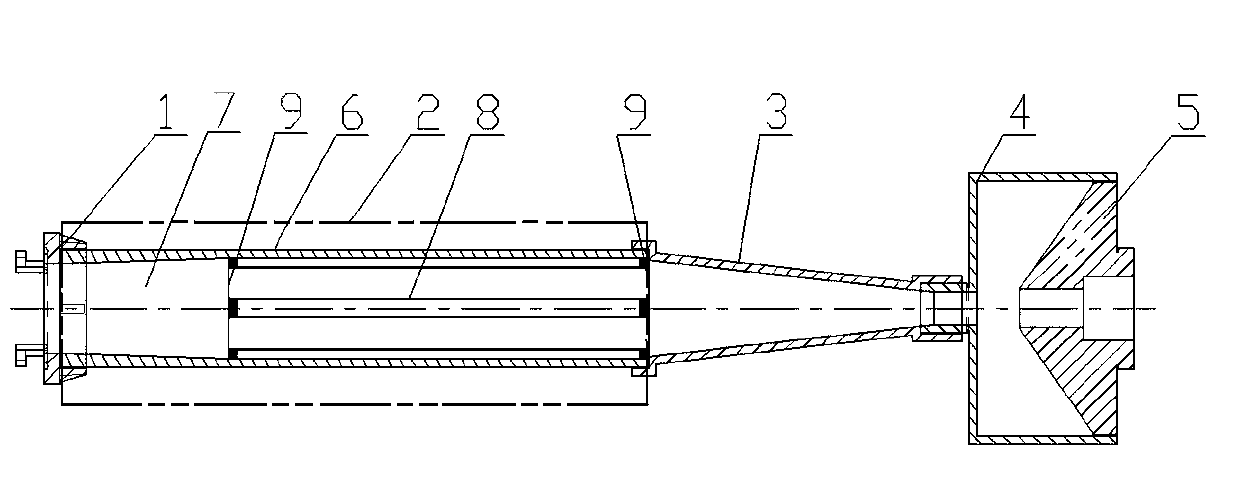

Pulsed jet fire-fighting lance

The invention provides a pulsed jet fire-fighting lance, which comprises a connecting piece, a rectifying device, a conical nozzle and a pulse nozzle hermetically and fixedly connected and communicated with one another in sequence, wherein the inlet of the rectifying device is hermetically and fixedly connected with the connecting piece; and other parts are in threaded connection and communication with one another through a sealing pipe. In the invention, the inlet end of the lance is provided with the rectifying device, so that the turbulence of jet is reduced, and the range is increased by 10-25 percent compared with the conventional lance; a continuous fluid flowing through an oscillation cavity is transformed into pulsed jet by using the special structure of the oscillation cavity without other additional auxiliary equipment; and the amplitude of outflow pressure is increased by 15-30 percent, so that the hitting dynamics and fire-fighting effect of the lance are enhanced under the condition of the same water flow, energy consumption is saved, and the performance of the fire-fighting lance is improved effectively. The pulsed jet fire-fighting lance can be widely applied to fire-fighting and cleaning systems of a fire-fighting system.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

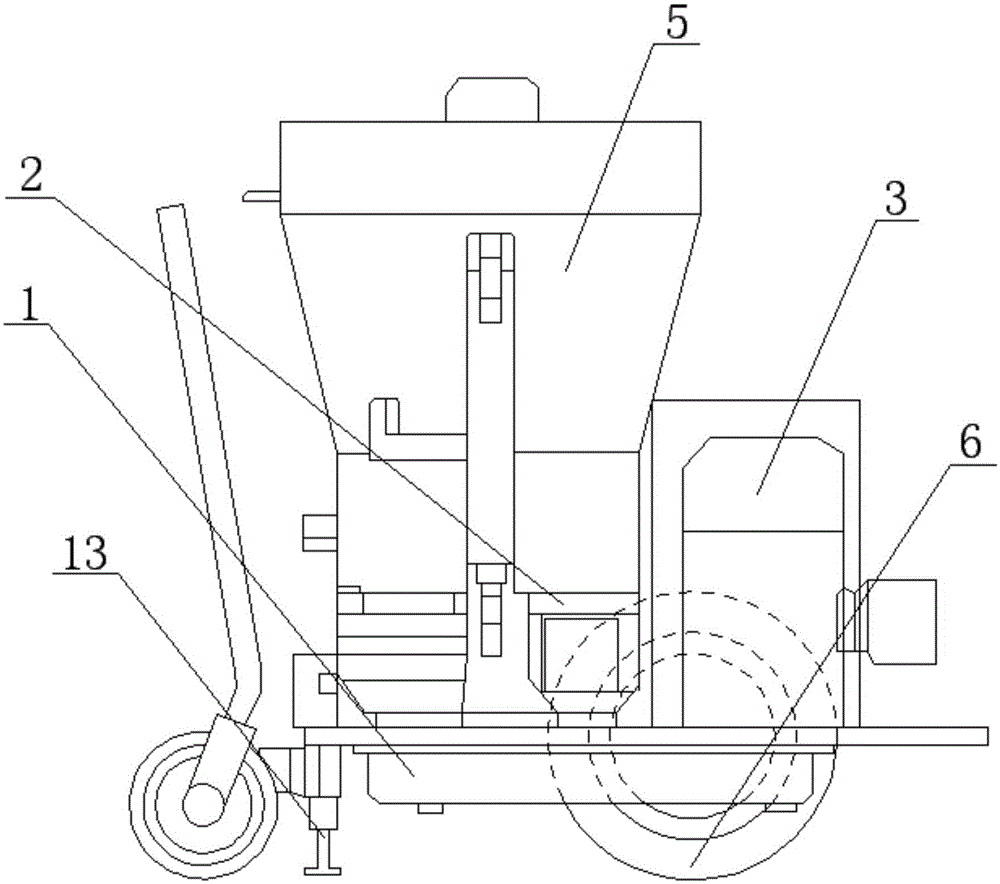

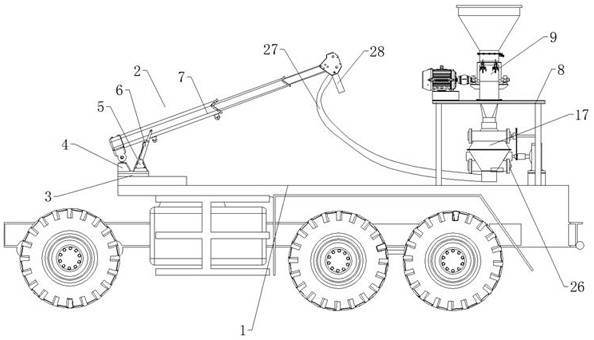

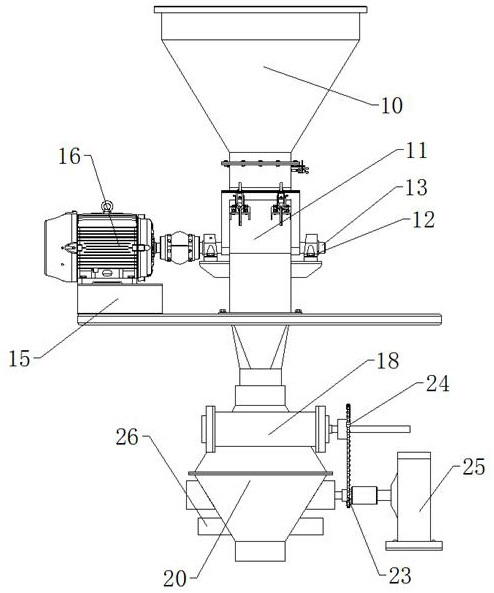

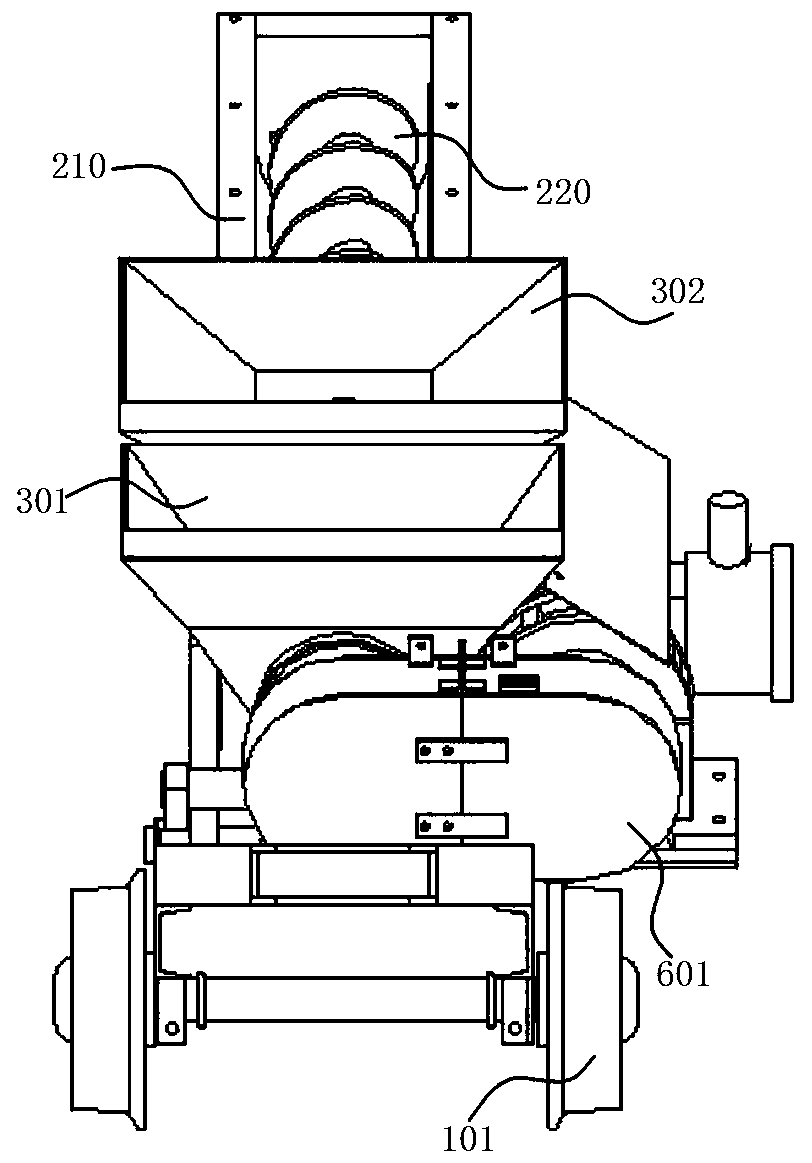

Remote dust-free concrete sprayer

InactiveCN105484771AReasonable designSimple structureUnderground chambersTunnel liningCoalEngineering

The invention provides a remote dust-free concrete sprayer and belongs to the technical field of concrete spraying devices used in underground coal mines. The remote dust-free concrete sprayer aims at solving the problems of short spraying distances and high springback rate of an existing sprayer. A feeding portion of the existing sprayer is improved, a conical feeder is adopted, at least two rotor material cups are annularly arranged on the surface of a feeding rotor of a cylindrical structure or a circular truncated cone shaped structure at intervals, the feeding rotor is in sealed connection with a feeding shell, the rotor material cups sequentially pass through a feeding port, a discharging port and a residual air port of the feeding shell along with the feeding rotor, when the rotor material cups gradually rotate to the discharging port of the feeding shell, an air supplementing port is communicated with the rotor material cups to enable materials in the rotor material cups to quickly enter a spraying portion, the rotor material cups continue to rotate along with the rotor and later pass through the residual air port of the feeding shell to discharge out residual air and materials in the rotor material cups so as to facilitate that the rotor material cups receive materials from a hopper portion again when continuing to rotate to the position of the feeding port.

Owner:ZOUCHENG TIANHE SCI & TECH

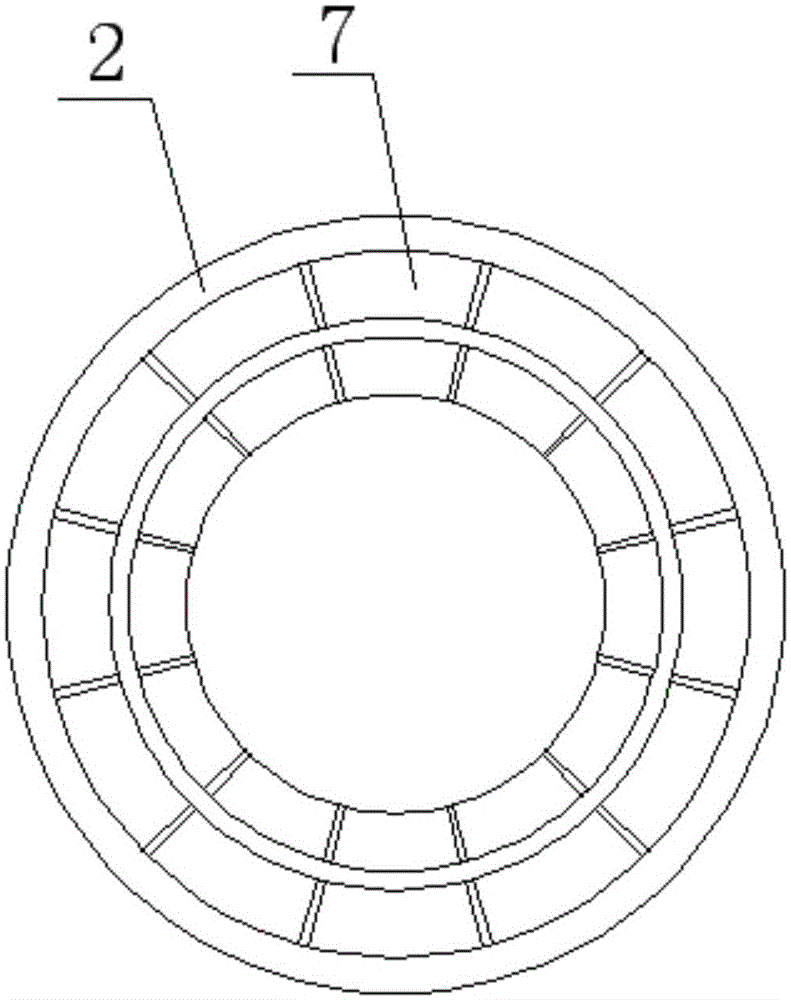

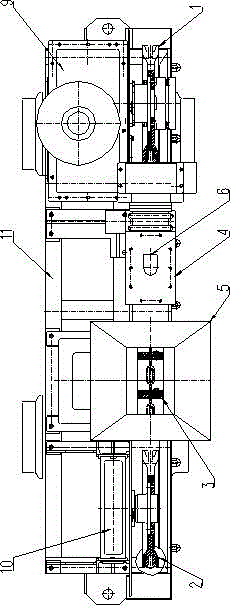

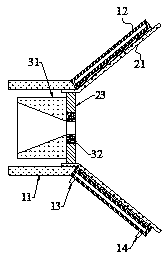

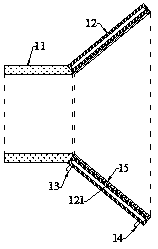

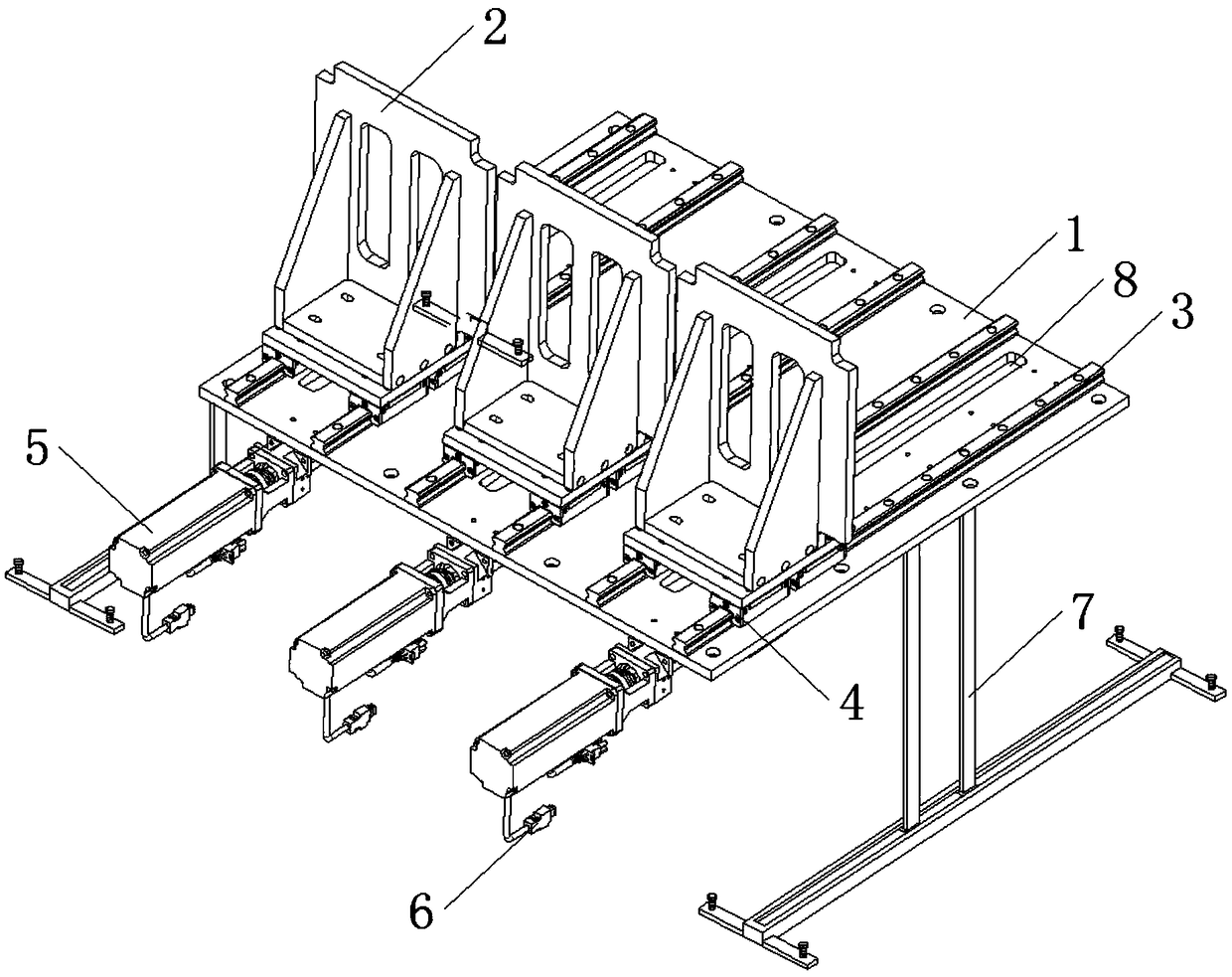

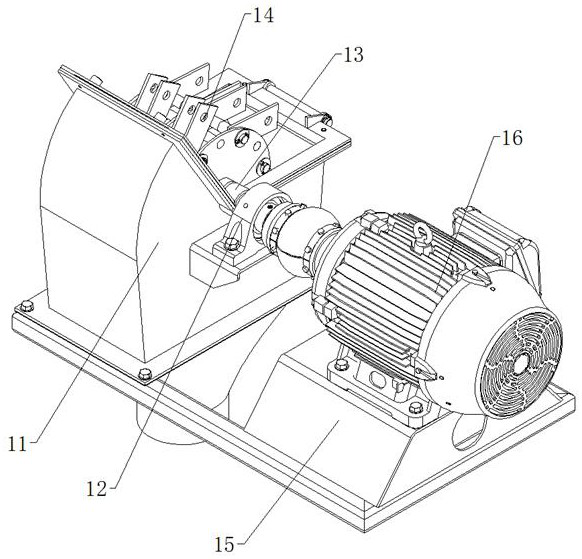

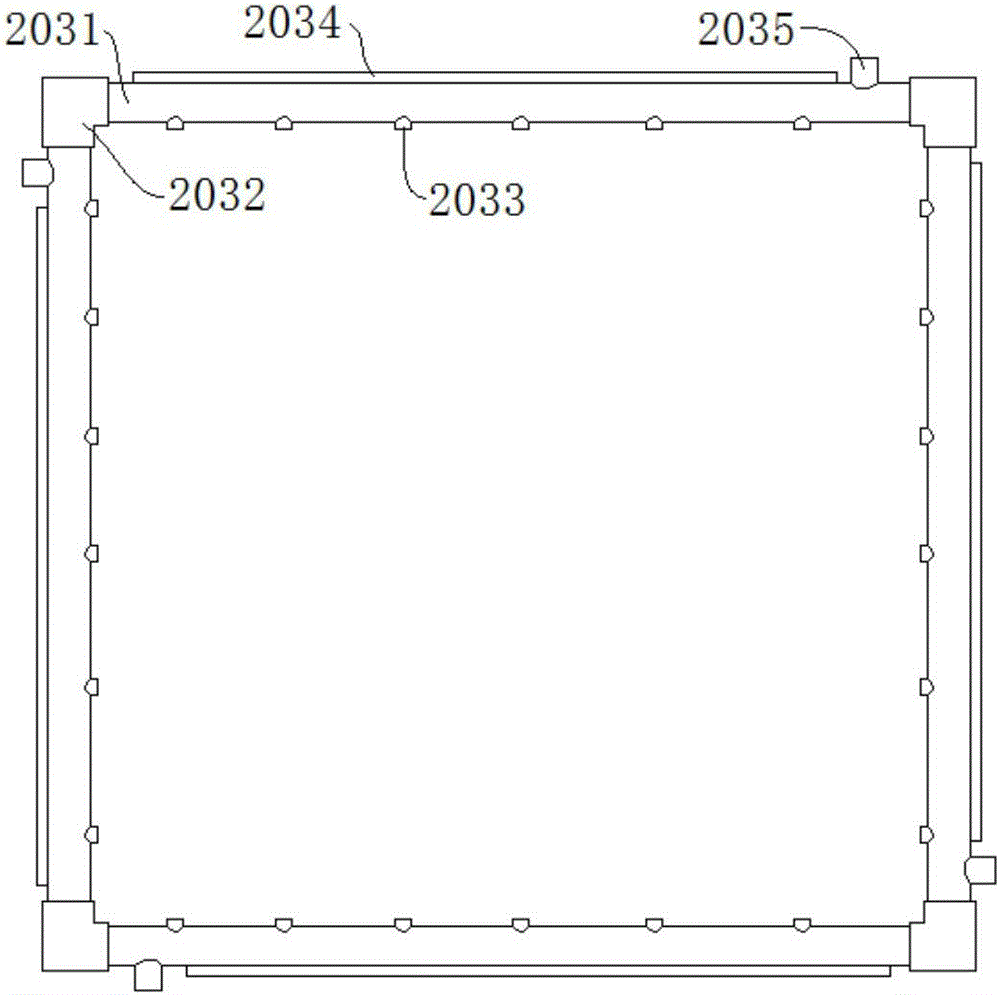

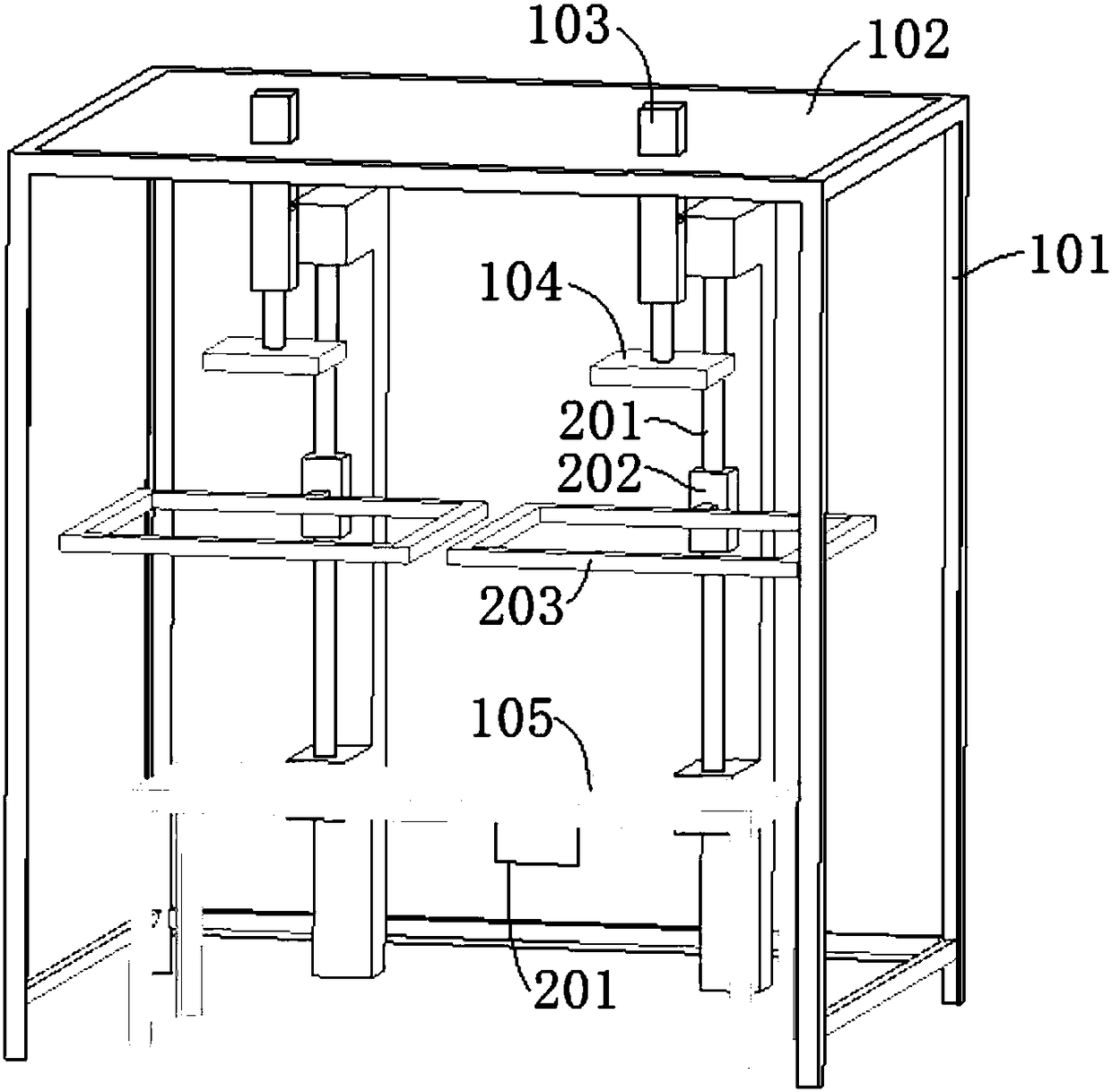

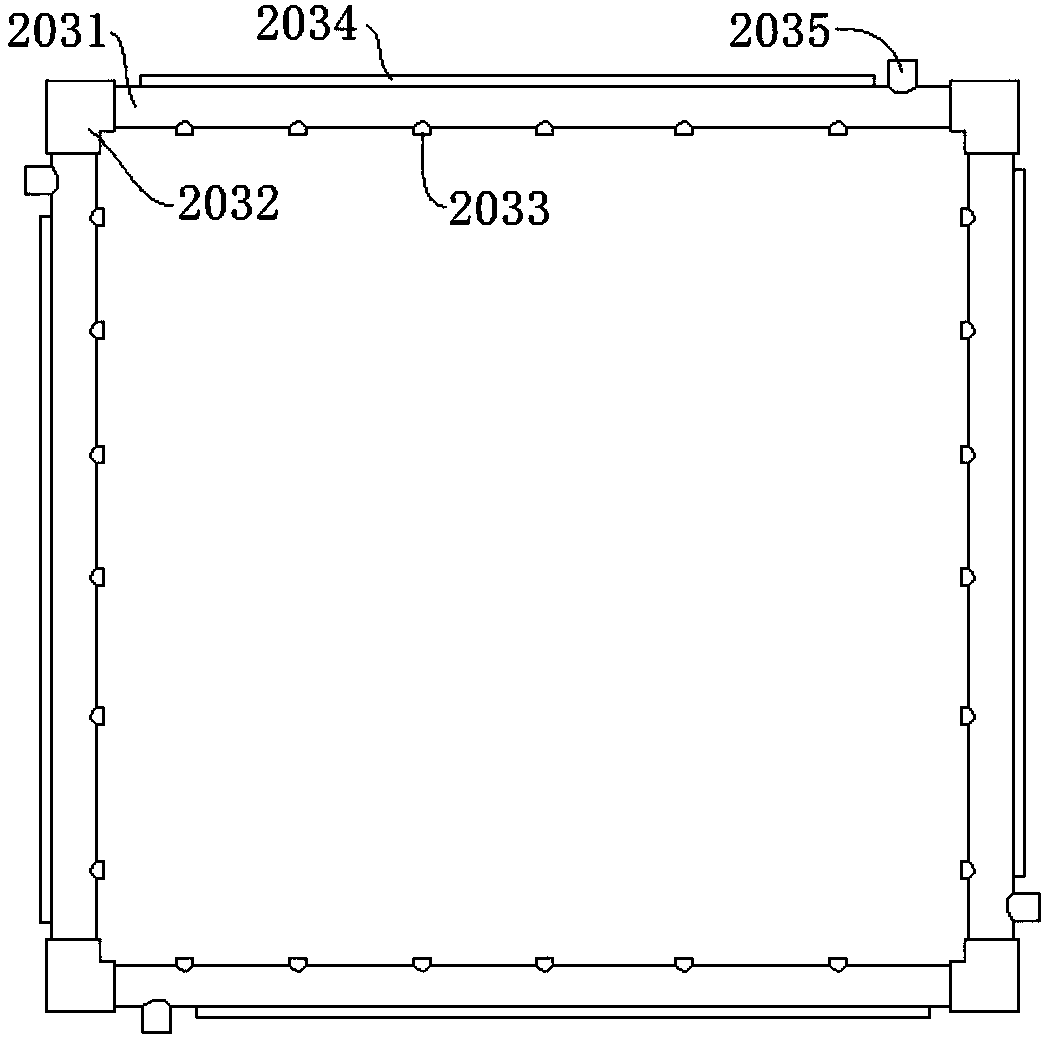

Mining rotor type variable shotcrete machine

InactiveCN105019921AVolumetric Efficiency MaximizationImprove Section UtilizationUnderground chambersTunnel liningShotcreteDrive motor

The invention discloses a mining rotor type variable shotcrete machine. The mining rotor type variable shotcrete machine comprises a frame, a rotor block, a drive motor, a gun head injection pipe and a hopper, wherein a plurality of U-shaped cavities penetrating through the rotor block and having fan-shaped sections are distributed in the rotor block in the circumferential direction; the gun head injection pipe comprises a conical spiral feeding pipe and a conical discharging pipe, one end, with smaller diameter, of the conical spiral feeding pipe is connected with an injection pipe base, and the other end is connected with one end, with larger diameter, of the conical discharging pipe; with the adoption of the U-shaped cavity structures, the fan-shaped cavities replace cylindrical cavities, so that the volume efficiency of the cavities realizes maximum, the section utilization rate of the rotor block is increased, air feeding and material discharging are more continuous and more uniform, the pulse phenomenon of material discharging is greatly reduced, and resilience and dust are reduced. Meanwhile, the gun head injection pipe is spliced by two sections of conical pipes, so that an injection material and water are mixed sufficiently and uniformly, the injection quality is improved, the injection layer is more compact, and homogeneity and strength are improved.

Owner:淮南久辉工贸有限责任公司

Head for injecting a fluid under pressure to break up ground from a borehole

InactiveUS7000714B2Improve jet qualityMinimize disturbanceLiquid/gas jet drillingFluid removalEngineeringNozzle

The present invention provides a head for injecting a fluid under pressure for breaking up the ground from a borehole and mounted at the end of a string of rods. The body of the drilling head has a bottom wall for mounting a mechanical drilling tool having a feed pipe, at least one injection nozzle, and duct-forming means for connecting the feed pipe with liquid at the inlet of said nozzle, the duct-forming means presenting a mean line having a radius of curvature that varies continuously, the right section of said duct-forming means decreasing regularly over at least half its length from its first end towards its second end. The injection head further comprises at least one pipe for feeding said mechanical tool, said pipe being connected at a first end to said duct-forming means and at a second end to a chamber disposed at the bottom end of said injection head and fitted with a controllable shutter member interposed between said chamber and the pipe for feeding said mechanical tool.

Owner:CIE DU SOL

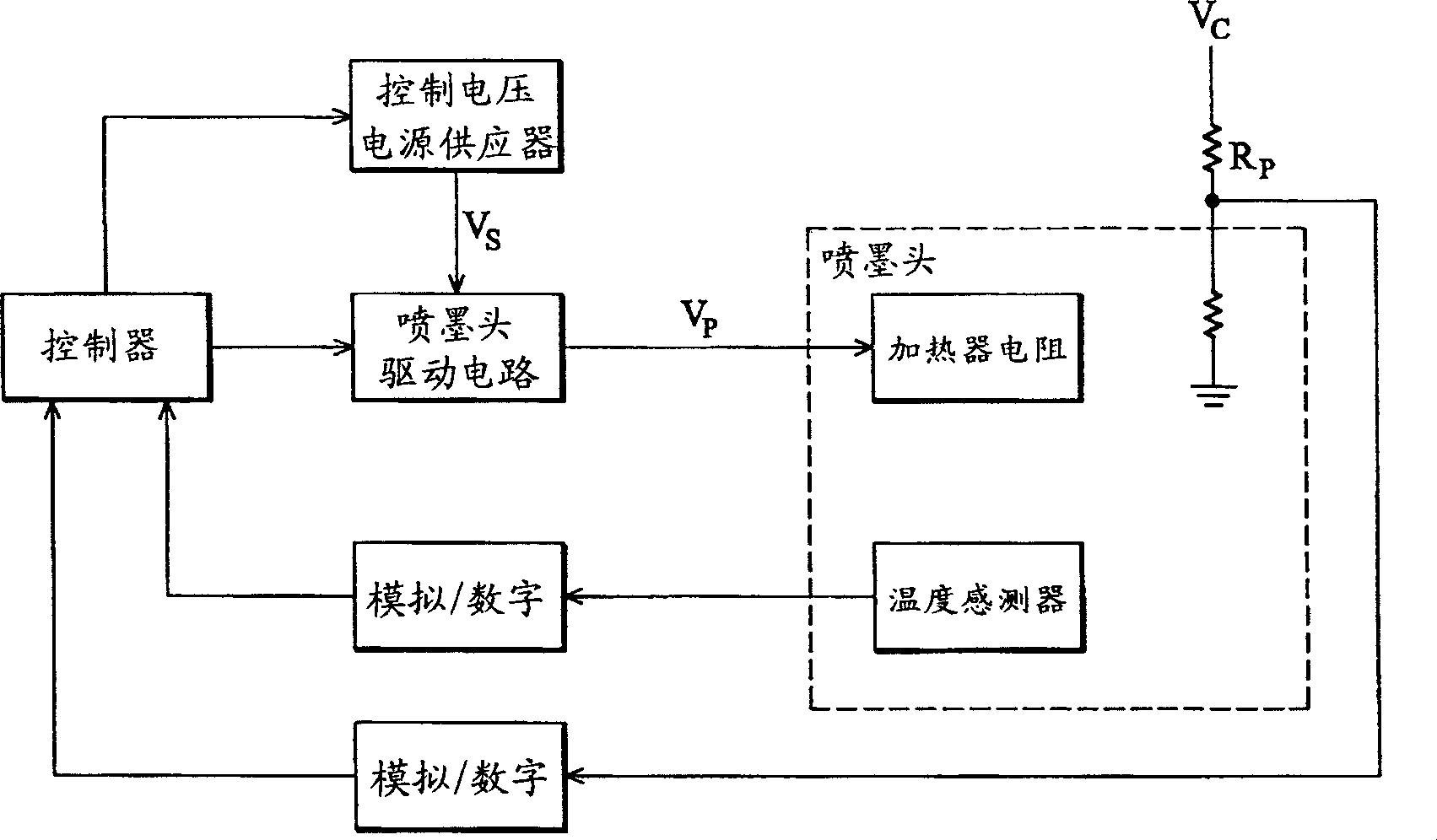

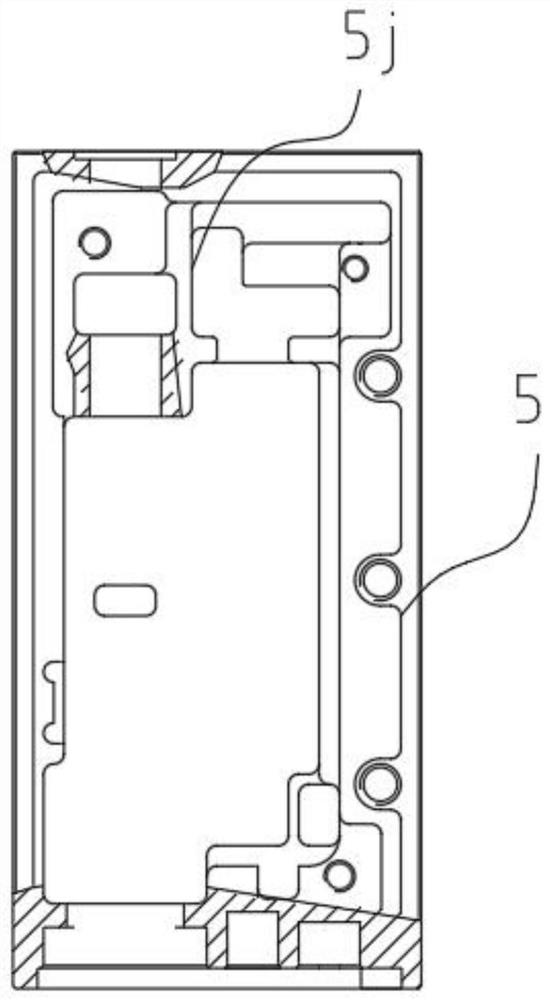

Micro fluid jet unit and method of improving micro fluid jetting quality

InactiveCN1672933AImprove jet qualityOther printing apparatusElectrical resistance and conductancePower efficient

The present invention provides one kind of micro fluid jet unit and the method of improving micro fluid jetting quality. One resistor sensing unit is used in the resistance detection of the heater in the micro fluid jet unit, and one signal control unit is used for regulating the driving signal based on the detection result, so as to improve micro fluid jetting quality and raise the use performance of the micro fluid jet unit.

Owner:BENQ CORP

Spraying method for construction of concrete for slope reinforcement of water-level-fluctuating zone

The invention relates to the technical field of reservoir slope construction, and discloses a spraying method for construction of concrete for slope reinforcement of a water-level-fluctuating zone. The spraying method includes the following steps that (1) the rock face is cleaned, loose rocks, pumice stone, dust, slag and other debris on the sprayed face are removed, for a soil slope, the slope isleveled and compacted, a spraying layer mark is arranged as required, the spraying layer thickness control mark adopts rebars or metal nails, the space between the rebars or the metal nails is 3-5 m,and the length of the extension part of the rebars or the metal nails is the thickness of sprayed concrete. According to the spraying method for construction of the concrete for slope reinforcement of the water-level-fluctuating zone, the space between the arranged rebars or the metal nails is 3-5 m, the length of the extension part of the rebars or the metal nails is the thickness of the sprayedconcrete, so that the rebars or the metal nails can be covered by the sprayed concrete after spraying of the concrete is completed, the spraying quality of the concrete is increased, after installation and debugging are also completed through a spraying machine, firstly water is injected, then ventilation is conducted, and pipelines are cleaned.

Owner:瑞派尔(宜昌)科技集团股份有限公司

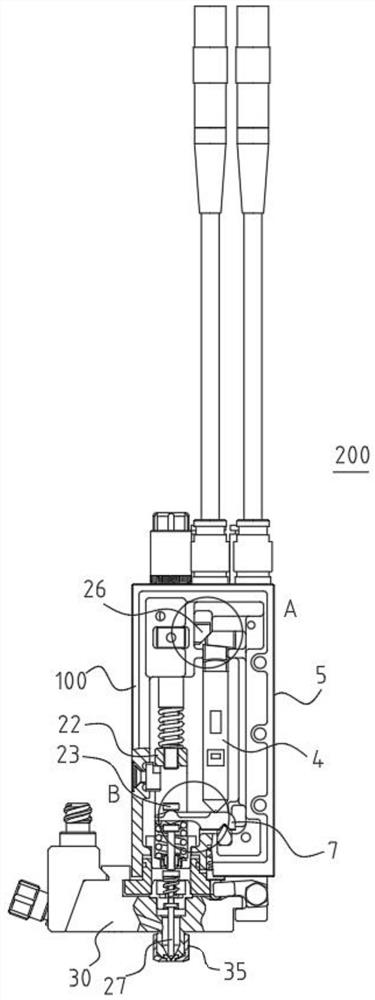

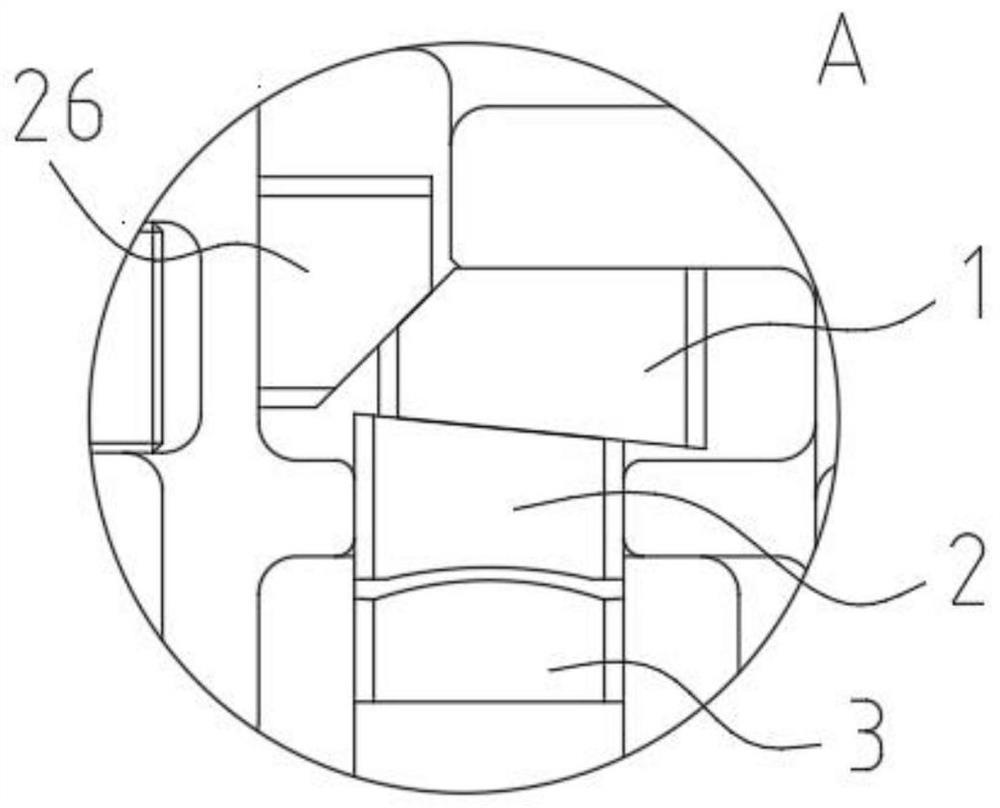

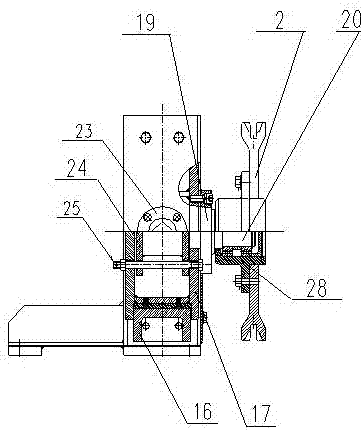

Fluid trace injection device

The embodiment of the invention discloses a fluid trace injection device. The fluid trace injection device comprises a base body, a lever, an actuator, a fluid seat, a nozzle, a guide seat and a movable element, wherein an execution mechanism mounting cavity is defined in the base body, and a positioning hole is formed in the base body; the lever is arranged in the execution mechanism mounting cavity, and the two ends of the lever are movable; the actuator is telescopically arranged in the execution mechanism mounting cavity and connected with one end of the lever; the base body is arranged onthe fluid seat; the nozzle is arranged on the fluid seat; a guide hole penetrating in the axial direction of the guide seat is defined in the guide seat, the lower end of the guide seat extends intothe mounting cavity and is in threaded connection with the fluid seat, and the upper end of the guide seat can extend into the positioning hole when the base body and the fluid seat are assembled; andthe movable element is arranged in the guide hole and can move in the axial direction of the guide seat, and the upper end of the movable element is connected with the other end of the lever in a clamped mode when the base body and the fluid seat are assembled and driven by the lever to move in the axial direction of the positioning hole. According to the fluid trace injection device, the servicelife is long, and the fluid injection quality stability is high.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

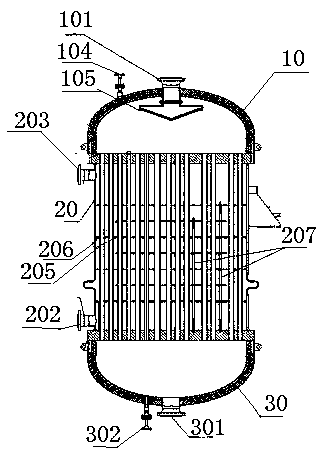

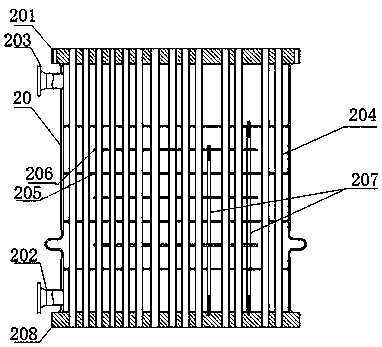

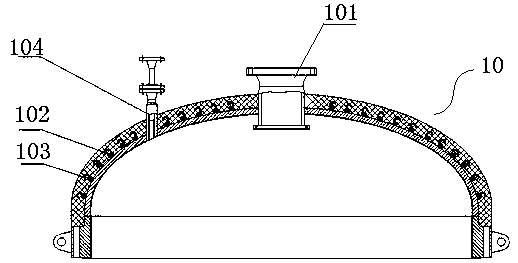

Methane hydrochlorination reactor

InactiveCN110947354AImprove liquidityImprove uniformityChemical/physical/physico-chemical stationary reactorsThermodynamicsWater chlorination

The invention discloses a methane hydrochlorination reactor. The methane hydrochlorination reactor comprises an upper sealing head, a shell and a lower sealing head which are fixedly connected in sequence from top to bottom, a feeding pipe is arranged at the upper part of the upper sealing head, and a discharging pipe is arranged at the bottom of the lower sealing head. The methane hydrochlorination reactor further comprises: an upper sealing plate which is fixedly connected to the upper end of the shell; a lower sealing plate fixedly connected to the lower end of the shell; a liquid inlet pipe fixedly connected to the lower part of the shell and positioned above the lower sealing plate; and a liquid outlet pipe fixedly connected to the upper part of the shell and positioned below the upper sealing plate; and heat exchange tubes, wherein the two ends of the heat exchange tubes are respectively fixedly connected with the upper sealing plate and the lower sealing plate to communicate with inner cavities of the upper sealing head and the lower sealing head.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Spreading nozzle

The invention discloses a spreading nozzle which comprises a spray pipe, wherein the spray pipe is internally provided with a burbling assembly; the burbling assembly is fixedly arranged on the inner wall of the spray pipe through threads; the burbling assembly comprises a shaft lever and a fixed ring; the shaft lever is positioned in the central part of the shaft ring; the flat surface of the fixed ring is vertical to the axis of the shaft lever; the fixed ring is fixedly connected with the shaft lever by virtue of a connecting rib; the outer circle of the fixed ring is provided with threads corresponding to the inner wall of the spray pipe; spiny bulge pieces are annularly arrayed on at least one of the upper and lower surfaces of the fixed ring. One detachable burbling assembly is arranged in the traditional spray pipe, so that the pitch spraying quality is improved; meanwhile, the burbling assembly is detached by virtue of the screwing of the threads, so that the inner wall of the spray pipe can be conveniently cleaned by virtue of the spiny bulge pieces; the spreading nozzle is simple in structure and relatively convenient to clean.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

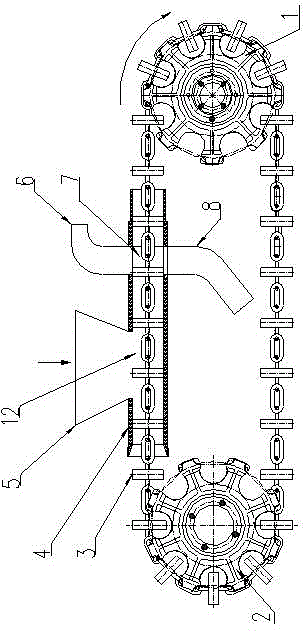

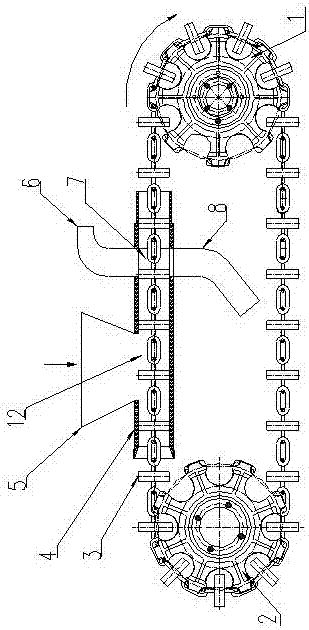

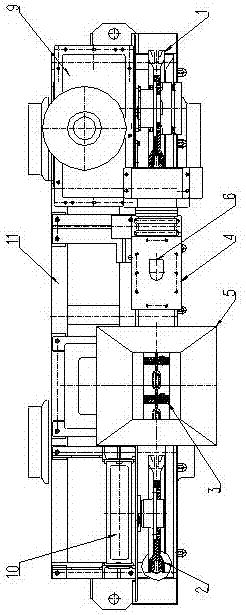

Improved push chain type concrete spraying machine

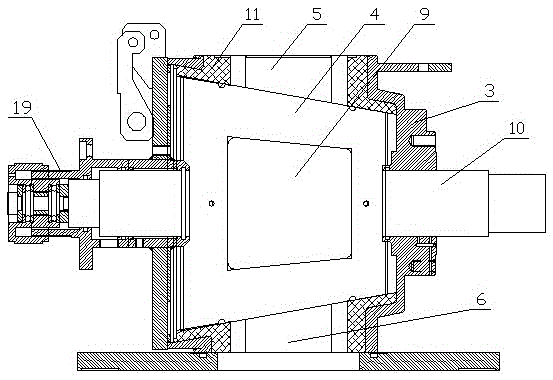

InactiveCN104895588ANot easy to cause blockageReduce shockUnderground chambersFoundation engineeringControl engineeringStructural engineering

The invention provides an improved push chain type concrete spraying machine. The improved push chain type concrete spraying machine structurally comprises a frame, a power output assembly, a driving chain wheel, a driven chain wheel assembly, a serial connection type piston assembly, a chain tightener assembly and a piston barrel assembly, wherein the driving chain wheel is connected with a power output shaft of the power output assembly, the driven chain wheel assembly is connected with the chain tightener assembly, the power output assembly and the chain tightener assembly are arranged at the left and right ends of the frame respectively, the piston barrel assembly is arranged above the middle of the frame, and the serial connection type piston assembly winds around the driving chain wheel and the driven chain wheel assembly annularly and passes through the middle of the piston barrel assembly.

Owner:李德安

Jacket cooling disassembling type flame spraying device

PendingCN111451058AEasy replacementImprove jet qualityLiquid spraying apparatusCoatingsPhysicsSpray nozzle

The invention relates to a jacket cooling disassembling type flame spraying device, which comprises an outer shell body, an inner shower nozzle arranged in the outer shell body, and a bushing, whereinthe outer shell body comprises a circular tube shaped connecting tube and a tapered tube shaped heat dissipation tube; the inner spray nozzle comprises a cylinder body of which the outer side wall isof a cylindrical structure; the central shaft of the cylinder body is provided with a circular truncated cone shaped first through hole; the center of the first end of the cylinder body is provided with a cylindrical boss; and the bushing comprises a tapered tube shaped first tube body and a circular tube shaped second tube body, wherein a clapboard is arranged in the second tube body. The outershell body, the inner shower nozzle and the bushing in the jacket cooling disassembling type flame spraying device adopt a detachable structure, so that an installation and replacement operation is simple and convenient. A jacket cooling way is adopted for the bushing so as to be favorable for controlling an injection temperature and improving subsequent injection quality; the inner surface of thebushing is subjected to surface treatment so as to be convenient to remove coking objects on the surface, and a situation that the bushing is frequently replaced is avoided.

Owner:王昊佳 +2

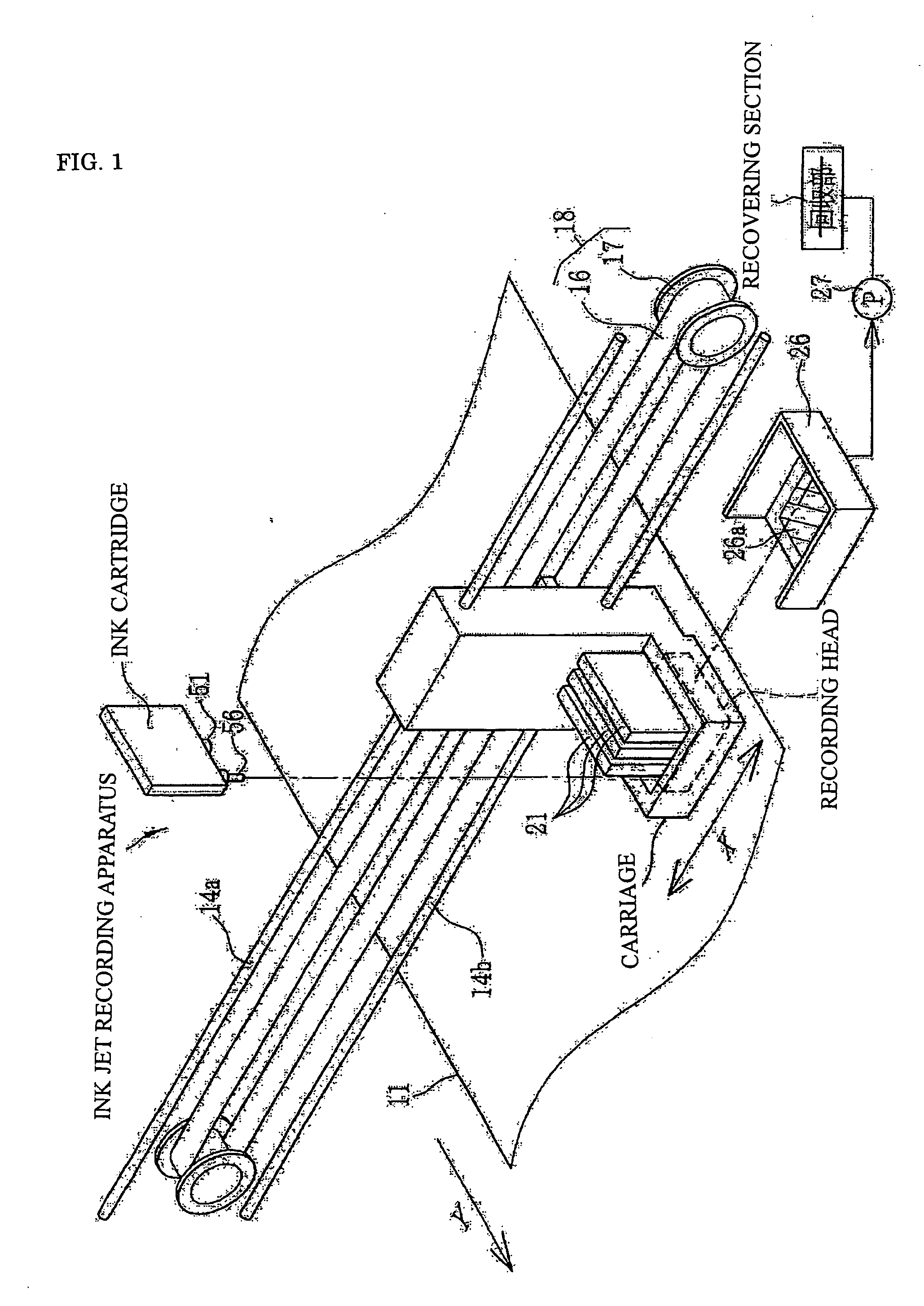

Ink unit containing ink and ink-contacting member

InactiveUS20070040883A1Improve ink-ejecting accuracyImprove jet qualityMeasurement apparatus componentsInksPolyolefinPhthalocyanine dye

An ink unit comprising an ink for use in an ink jet recording apparatus; and a liquid-contacting member that contacts with the ink, wherein the ink comprises a phthalocyanine dye of a specific structure which has an oxidation potential of 1.0 V (vs SCE) or more, and wherein the major component of the ink-contacting member is a polyolefin containing [1] a specific hydrotalcite-like compound, [2] a fatty acid and / or fatty acid derivative, [3] a phenolic antioxidant having an isocyanurate skeleton or [4] an alkyl-substituted benzylidenesorbitol.

Owner:FUJIFILM CORP

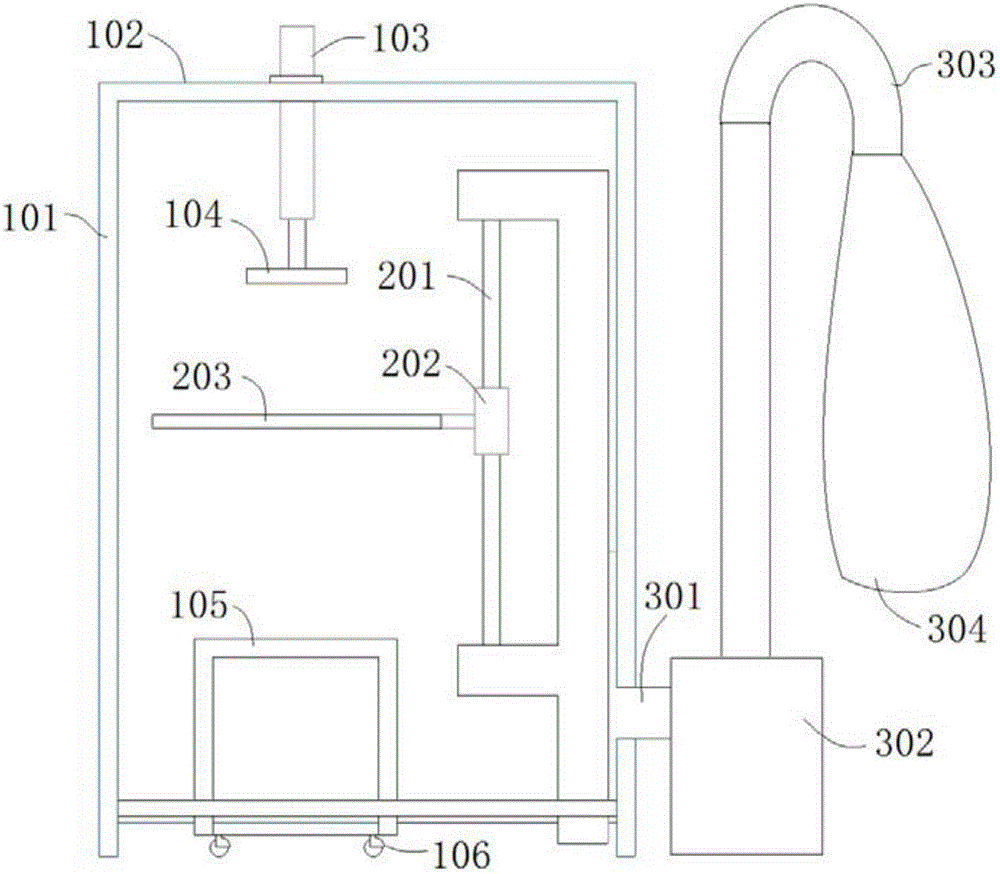

Device and method of liquid preparation jetting for gene engineering

InactiveCN109013102AImprove research efficiencyImprove efficiencyLiquid spraying apparatusSocial benefitsAir pump

The invention discloses a device and a method of liquid preparation jetting for gene engineering. The injection device of the liquid preparation comprises a mounting plate, sliding bases, an upper sliding rail, an upper sleeve base, a liquid tank, spraying frames, a supporting plate, a through groove, a welding block, an air pump, a mounting base, a sliding column, a connecting plate, a lower sleeve base, a bolt hole, an inserting plate, a connecting bolt, a bolt sleeve, a screw groove, a sleeve plate, a rolling groove, a power storage plate, movable plates, a motor and a grounding plate. Thedevice and the method of liquid preparation jetting for the gene engineering has the beneficial effects that the device is provided with plats for different gene engineering through a plurality of sliding bases, the one-to-one spraying frames are used for spraying, so that the efficiency of gene engineering research is improved, and the space utilization rate of the device is improved; the two movable plates of the supporting plate are connected inside the rolling groove through the motor at the bottom in a clamped mode, the movable plates are supported through the movable plates, so that contrastive analysis on the liquid injection research carried out by working personnel is facilitated, and the quality of the gene engineering research is improved; and the device of the liquid preparation jetting is convenient to operate, stableness and firmness are achieved, good social benefits is achieved and the device and the method are suitable for popularization and use.

Owner:佟可新

Atomizable wet spraying machine for soil environment treatment engineering of waste mining area

InactiveCN111802028AMix thoroughlyImprove jet qualityHops/wine cultivationTurf growingGear wheelElectric machinery

The invention relates to the technical field of wet spraying machines, in particular to an atomizable wet spraying machine for soil environment treatment engineering of a waste mining area. The atomizable wet spraying machine comprises a compartment; a crushing device is arranged on the upper side of a mounting frame; the crushing device comprises a discharging box, a crushing box, a crushing shaft mounting seat, a crushing shaft, a crushing cutter, a motor mounting seat and a crushing motor; a conveying discharging and scattering device comprises a conveying and discharging box, a conveying and discharging spiral shaft, a scattering and discharging box, a scattering shaft, a scattering rod, a driving gear, a driven gear and a scattering motor; and a nozzle is arranged at the position, away from the lower side of the scattering and discharging box, of a spraying pipe. Grass seeds, fertilizer and soil can be crushed and mixed through the crushing device; the discharging speed can be effectively controlled through the discharging spiral shaft; meanwhile, the scattering shaft in the scattering and discharging box is matched with the discharging speed to operate; and the materials arescattered and mixed again through the scattering rod, so that the grass seeds, the fertilizer and the soil are mixed more sufficiently and thoroughly, and the spraying quality and efficiency of the wet spraying machine are improved.

Owner:苏州聚臻阳生物环保科技有限公司

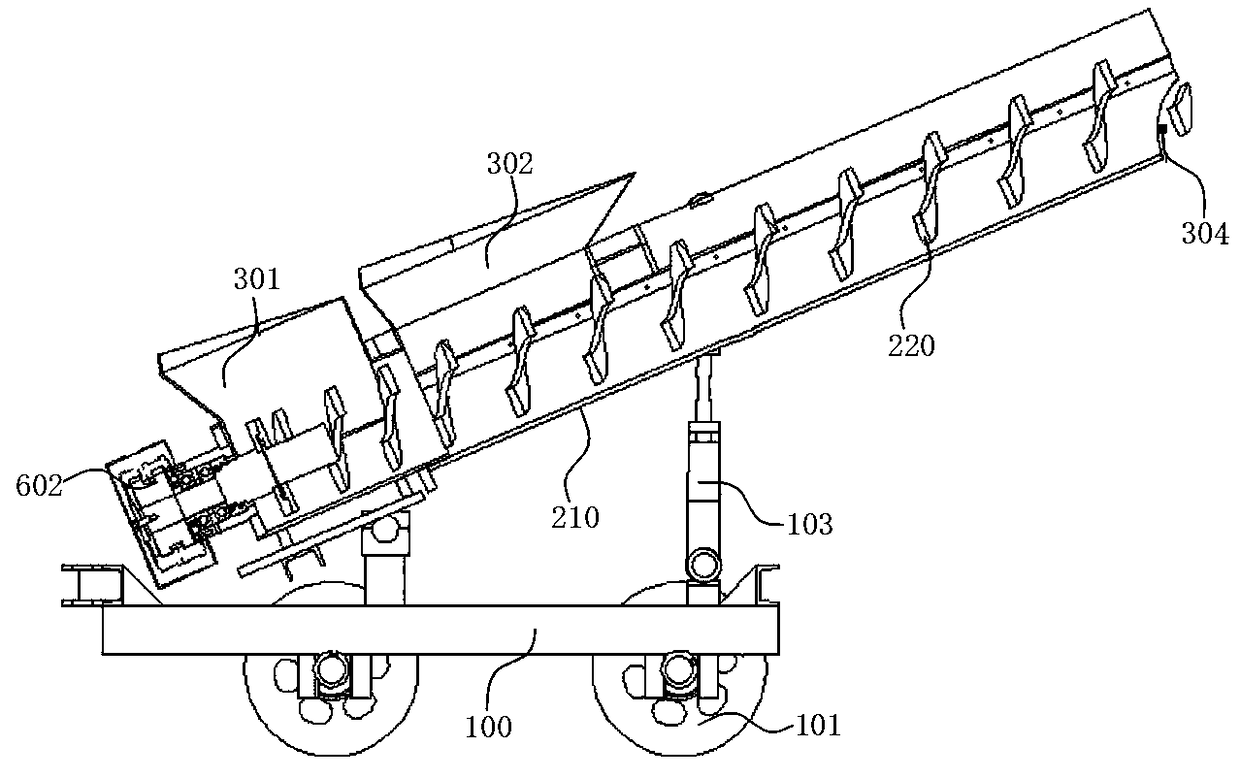

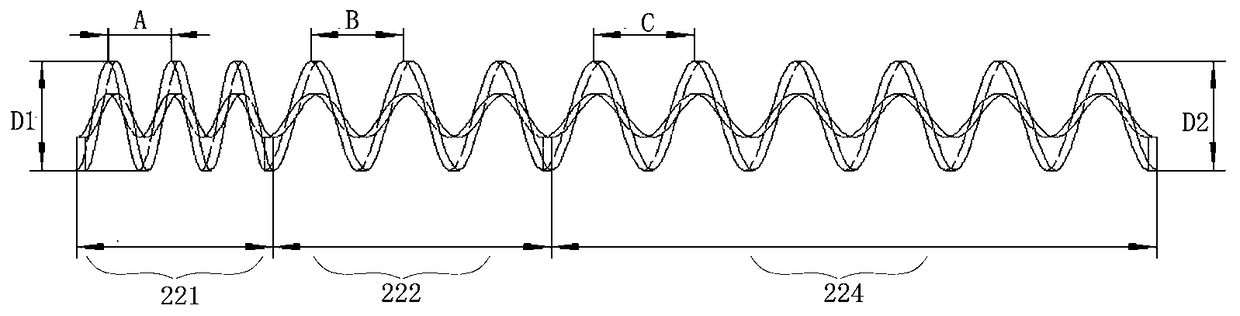

Shaftless spiral material mixing, stirring and feeding machine

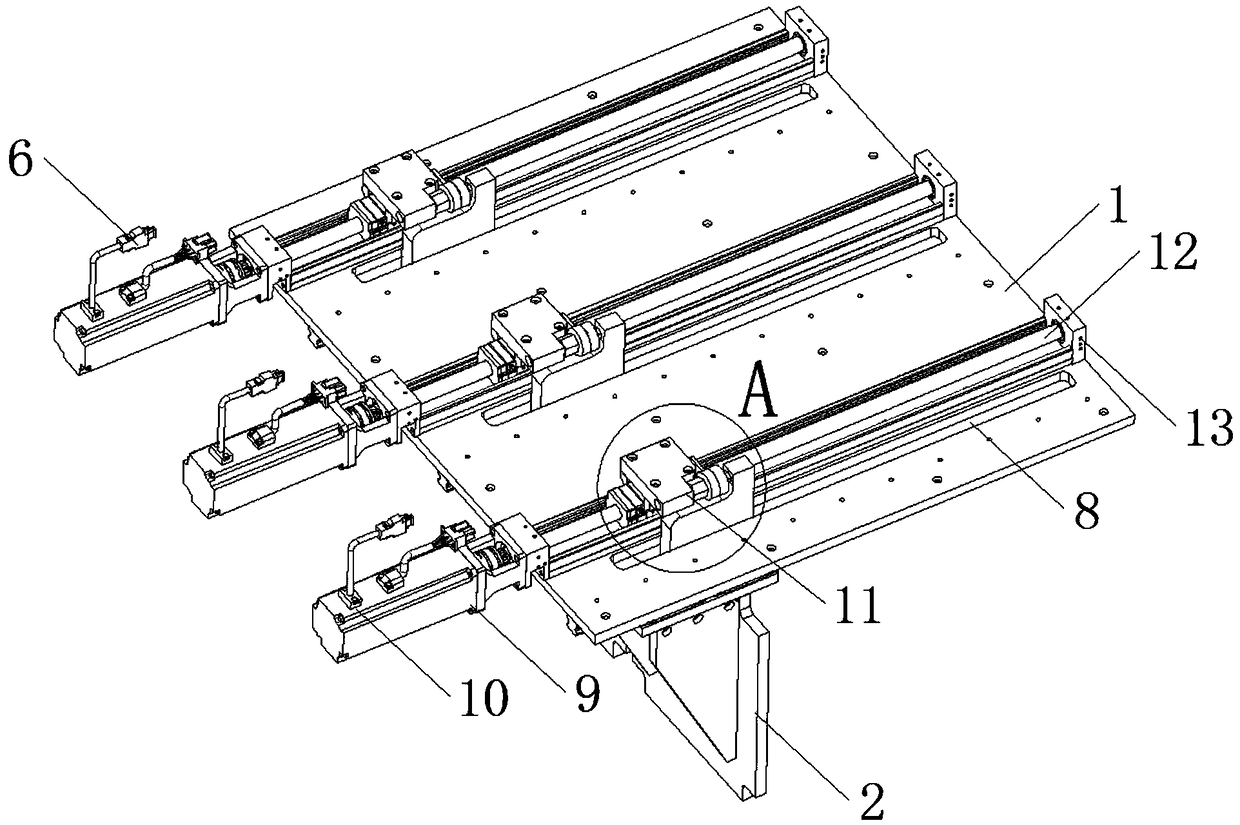

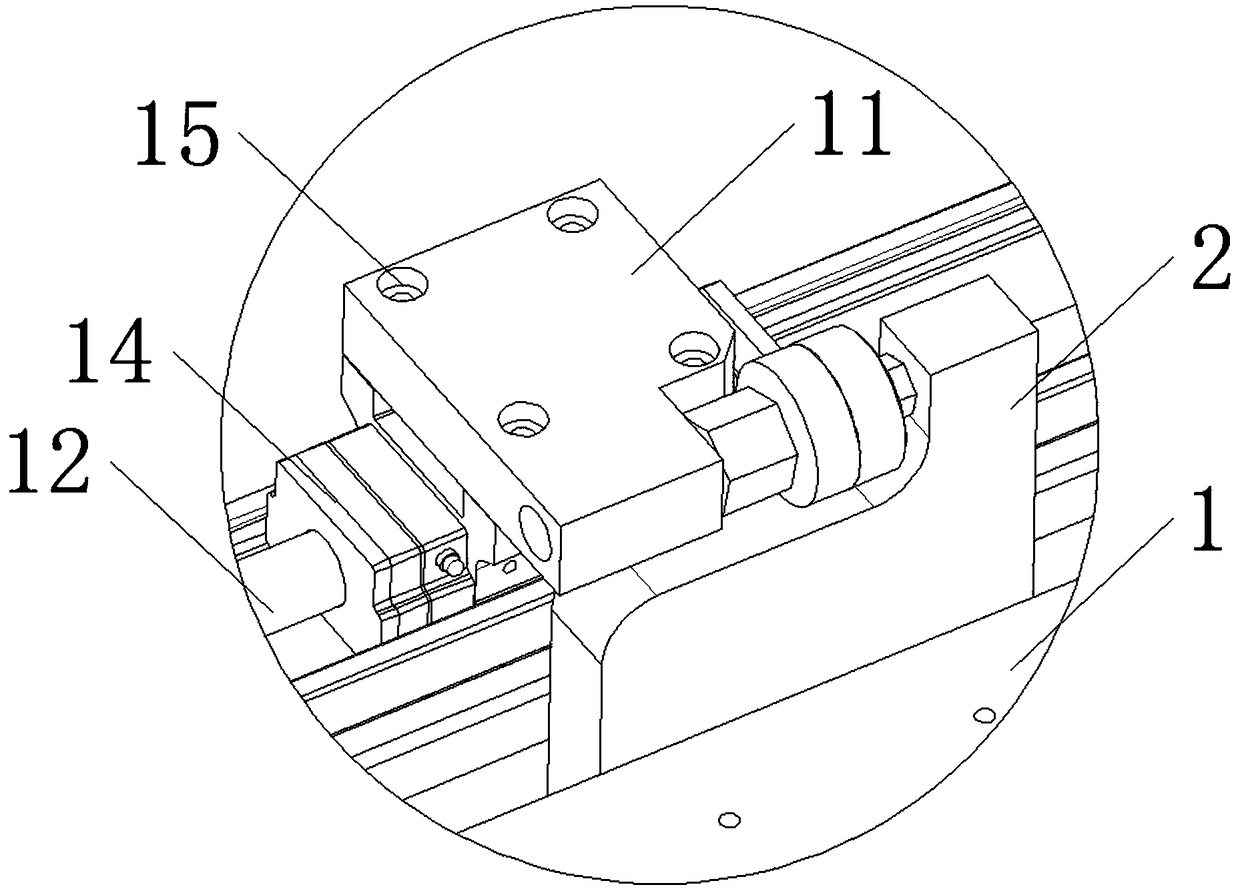

ActiveCN109502373AMeet performance requirementsHigh precisionConveyorsLoading/unloadingMechanical engineeringTextile

The invention belongs to a shaftless spiral material mixing, stirring and feeding machine. The shaftless spiral material mixing, stirring and feeding machine comprises a base, a main stirring shell, amain shaftless spiral and a power assembly. The main stirring shell is arranged on the base in a supporting manner. Multiple feeding bins are arranged on the main stirring shell. The feeding bins include the first feeding bin and the second feeding bin. A discharge port is formed in the end portion of the main stirring shell. The main shaftless spiral is arranged in the main stirring shell in a matched manner. The main shaftless spiral is of a sectional type structure. The main shaftless spiral at least comprises a first main spiral section and a second main spiral section. The first main spiral section and the second main spiral section correspond to the first feeding bin and the second feeding bin correspondingly. The formed shaftless spiral material mixing, stirring and feeding machineis compact in structure, convenient to move and free of bonding and does not need to be cleaned, the guniting work efficiency is improved, the guniting work labor intensity is lowered, and the spraying quality is improved.

Owner:河南省煤科院科明机电设备有限公司

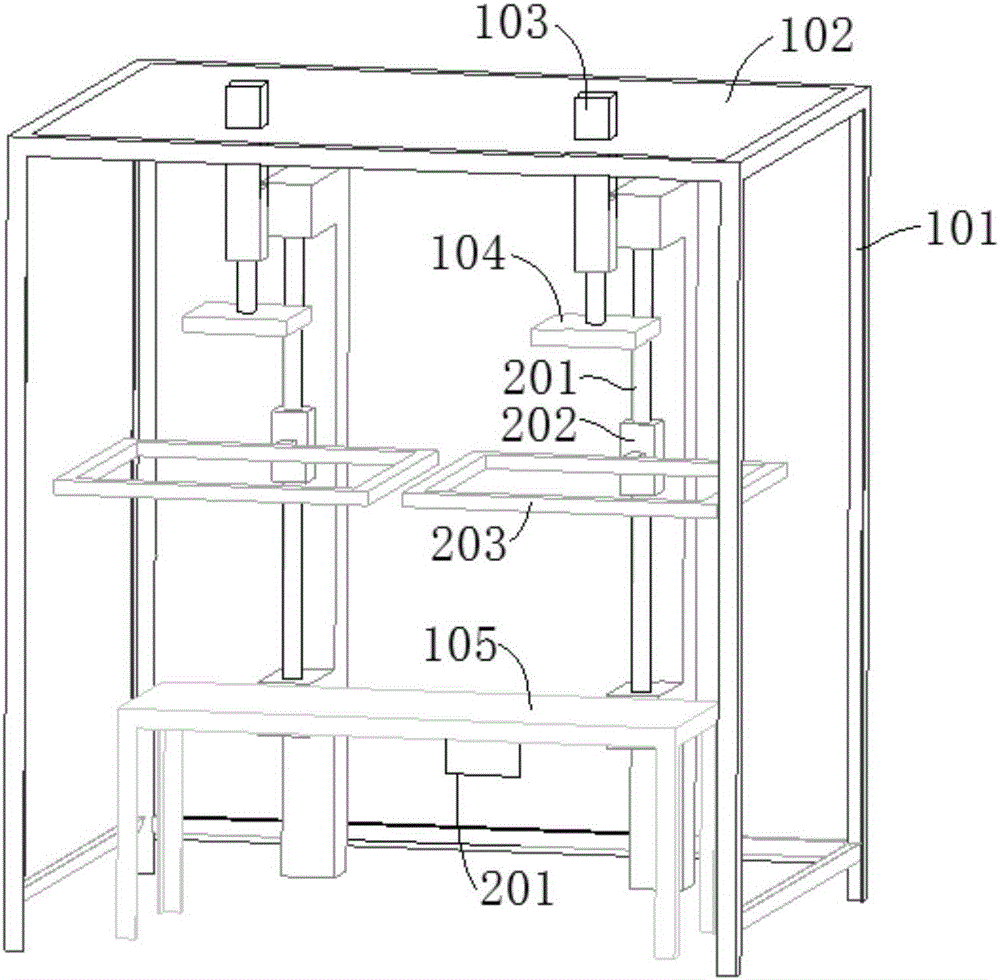

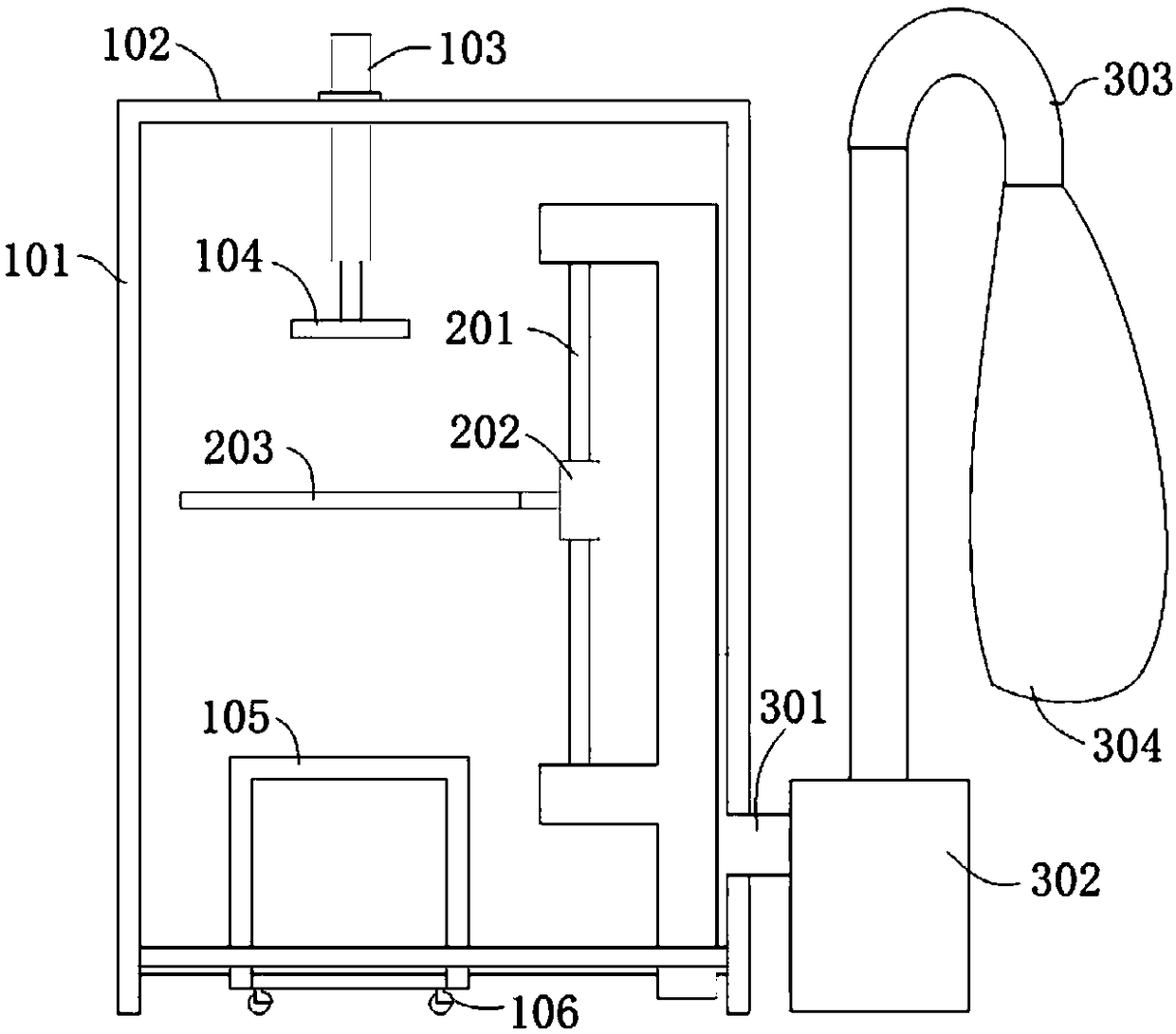

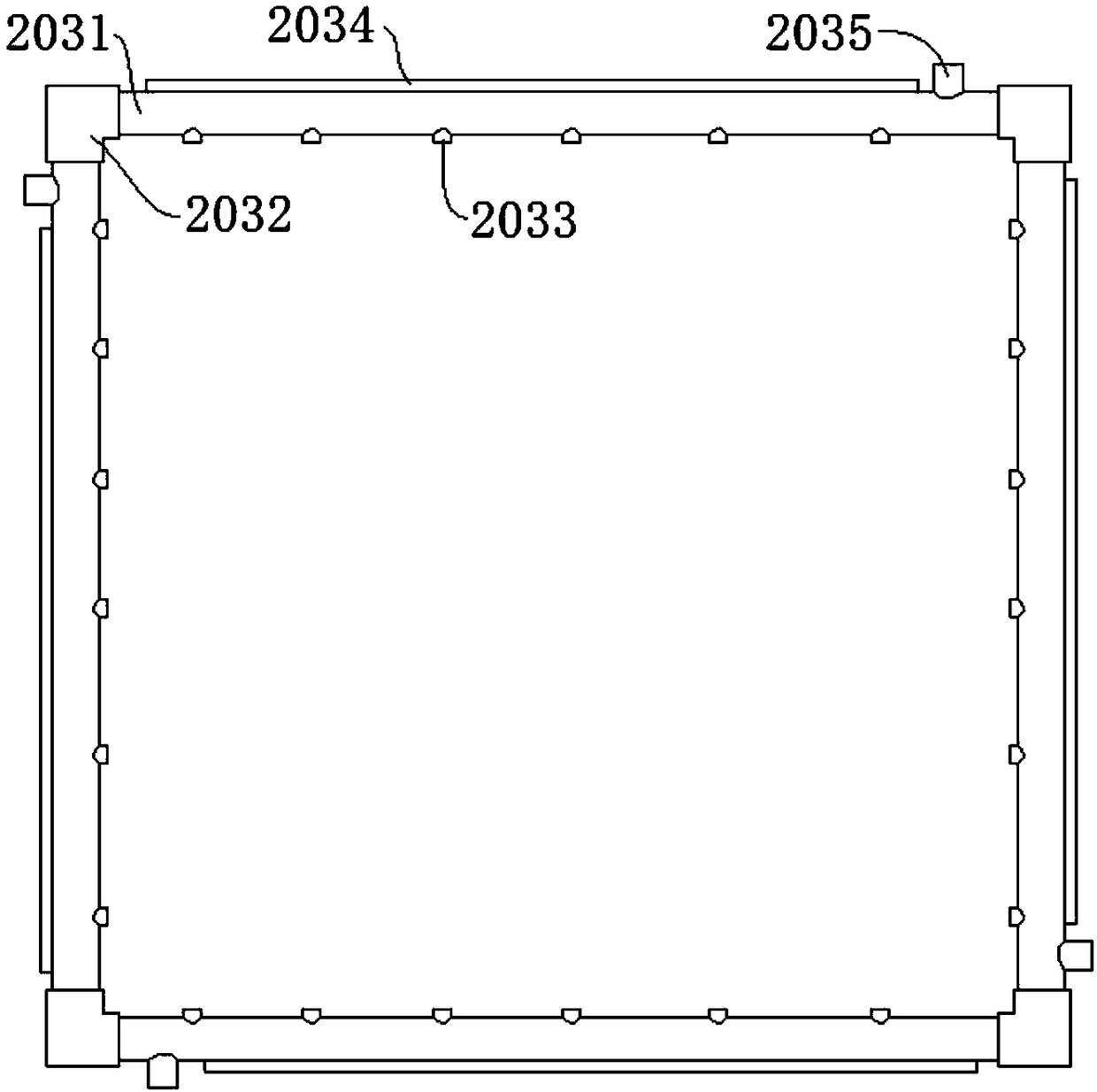

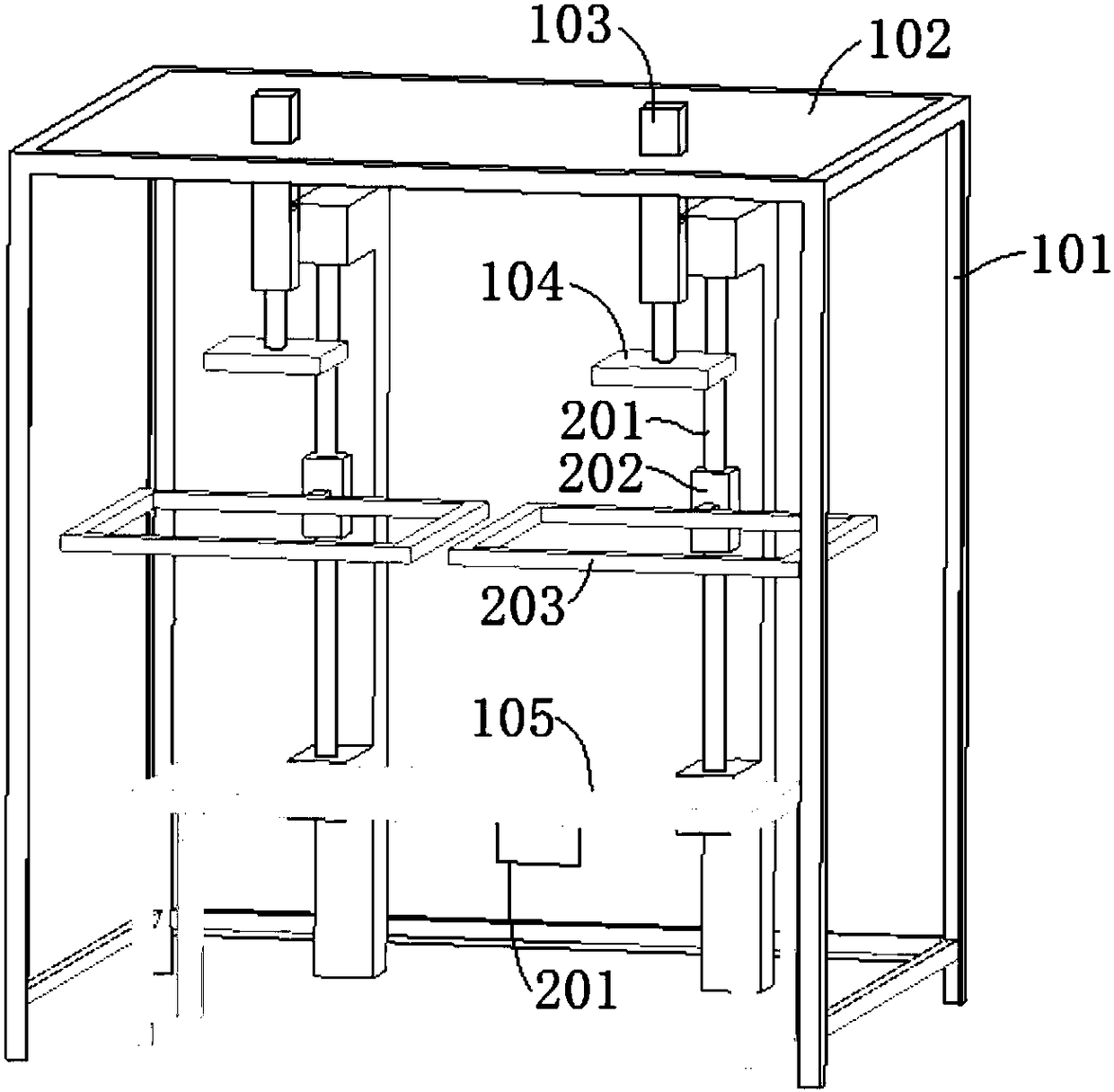

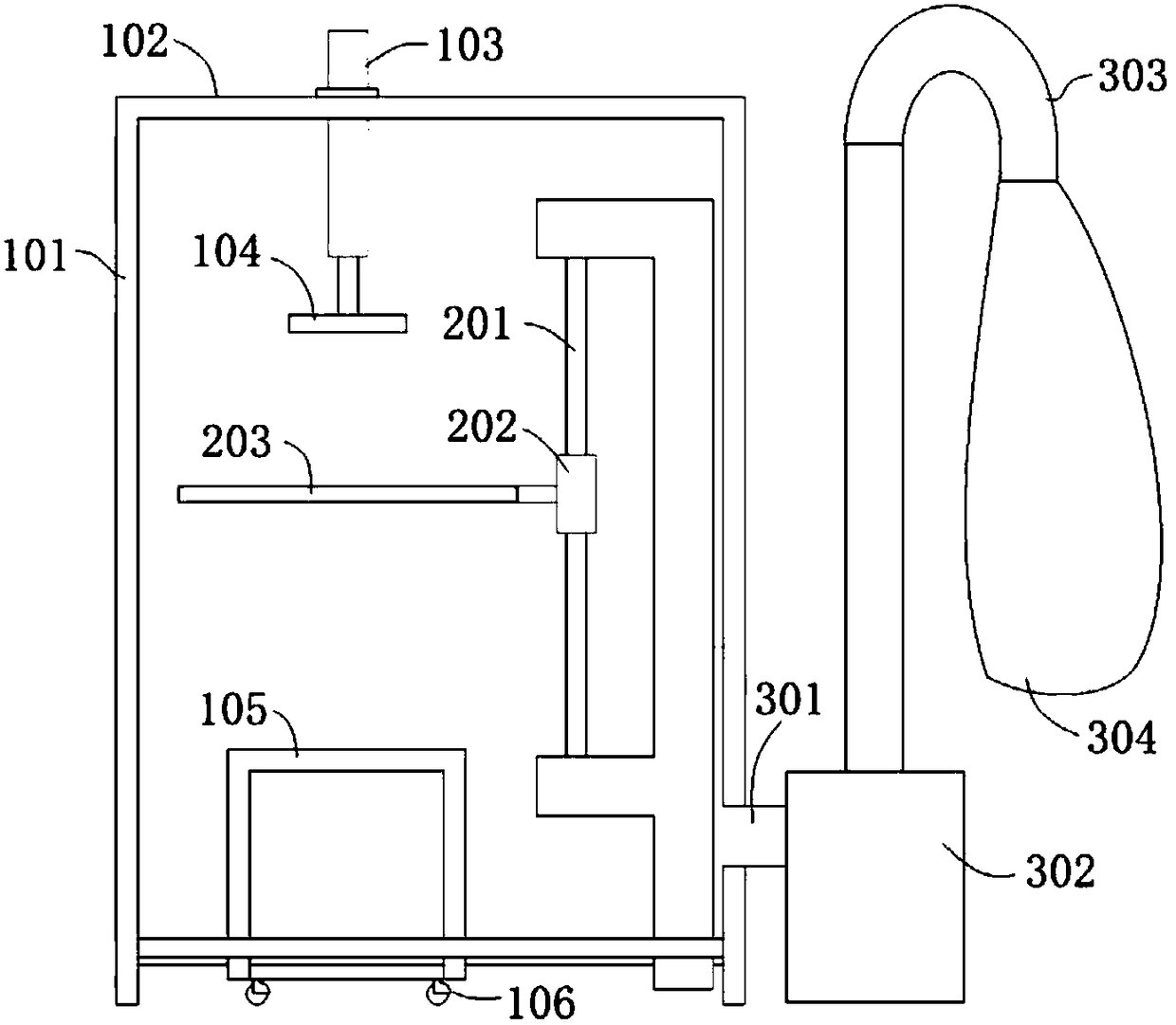

Closed-type washing machine top cover plate dedusting method

ActiveCN106111632AAvoid enteringImprove uniformityDirt cleaningCleaning using gasesEngineeringMechanical engineering

The invention discloses a closed-type washing machine top cover plate dedusting method and belongs to the field of dedusting equipment. The dedusting method removes dust through a dedusting system. The dedusting system comprises a supporting mechanism and a cleaning mechanism, wherein the supporting mechanism comprises a support, cylinders and a working stage; the vertically downward cylinders are installed on a top plate of the support; pressure plates are connected to piston rods of the cylinders and used for compressing workpieces; lifting mechanisms are used for controlling jet mechanisms to move up and down; and the side wall or the top of the support is connected with a dedusting device. According to the dedusting method, all faces are subjected to jet processing one by one, dedusting treatment can be conducted while cleaning is conducted, cleaning treatment is conducted through vertical movement of jet pipes, the cleaning efficiency and quality are remarkably improved, the workshop environment is improved, and injuries to workers is reduced.

Owner:马鞍山甬兴模塑有限公司

Mining method for jetting concrete in wet type

ActiveCN102733823BReduce cloggingAvoid restrictionsUnderground chambersTunnel liningShotcreteMining engineering

The invention relates to a mining method for jetting concrete in a wet type; a method comprises the following steps: preparing cement slurry; stirring gravel mixing material; starting air source to input high pressure air to a gravel mixing material transport pipeline in a jetting procedure; and inputting the cement slurry to a cement slurry transport pipeline through transport equipment; after jetting the cement slurry by a nozzle, adding the gravel mixing material to a jetting machine; under the action of the high pressure air, mixing and stirring the cement slurry and the gravel mixing material; finally, jetting the concrete from the nozzle. According to the invention, the method depends on current jetting equipment; a transport distance (larger than or equal to 60m) of jet concrete is can be increased greatly on a condition of ensuring invariable wet-type concrete jetting advantages; simultaneously, the method effectively avoids problems that large-scale stirring is used hardly and concrete transport equipment is limited under a coal well; production efficiency and jetting quality are improved greatly; in addition, powder dust concentration near the jetting machine is less than or equal to 10mg / m<3>.

Owner:河南省煤科院科明机电设备有限公司

Spraying device with replaceable nozzle and convenient to clean

PendingCN114472027APrevent floatingGood for healthNon-rotating vibration suppressionSpray nozzlesWorking environmentStructural engineering

The invention discloses a nozzle-replaceable spraying device convenient to clean, which comprises a device main body structure, one side of the device main body structure is connected with a coating collector structure for ensuring a working environment, the bottom of the device main body structure is connected with a damping seat structure capable of buffering, and the bottom of a conveying device is connected with a fixing block structure with a pressurizing effect. According to the coating spraying device, drifting coating is collected through the protective door and the coating collector structure, the working environment is improved, the surface of the spraying device is comprehensively cleaned through the spring brush, the coating in air is prevented from being adhered, and the coating spraying device is convenient to use. And a cleaning brush is driven by a hydrodynamic plate to clean the interior of the flow guide pipe structure, blockage caused by coating adhesion is prevented, and the nozzle structure is convenient to replace through separation of a fixing bolt and a fixing groove.

Owner:江苏州际数码印花有限公司

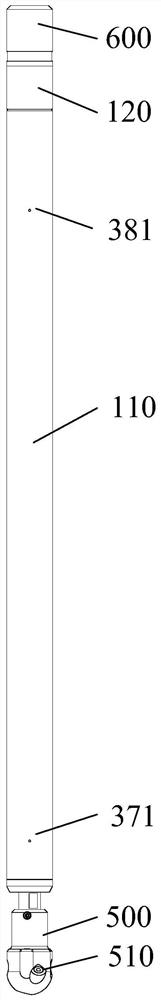

Rotary speed-limiting floating jet tool

ActiveCN113187400AGuaranteed fatigue lifeIncrease lossEarth drilling toolsLiquid/gas jet drillingRotational axisCoiled tubing

The invention provides a rotary speed-limiting floating jet tool. The rotary speed-limiting floating jet tool comprises an outer cylinder and a rotating shaft, wherein the rotating shaft is installed in the outer cylinder in a rotatable and axial reciprocating movement mode, a liquid passing channel is formed in the rotating shaft, the front end of the rotating shaft is provided with a spraying hole used for centrifugal spraying, the rear end of the rotating shaft communicates with the outer cylinder, the spraying hole communicates with the liquid passing channel, and a speed limiting structure is arranged between the outer cylinder and the rotating shaft; the rotating shaft is arranged to be driven by liquid conveyed into the liquid passing channel from the outer cylinder, so that rotation and axial reciprocating movement are achieved; the speed limiting structure is used for limiting the rotating speed of the rotating shaft, and the spraying hole is used for centrifugally spraying the liquid outwards. The rotary speed-limiting floating jet tool is used in cooperation with a coiled pipe, key jet treatment can be carried out on a certain specific area without the need for the coiled pipe to take up and down, and the fatigue life of the coiled pipe is effectively guaranteed.

Owner:CHINA OILFIELD SERVICES

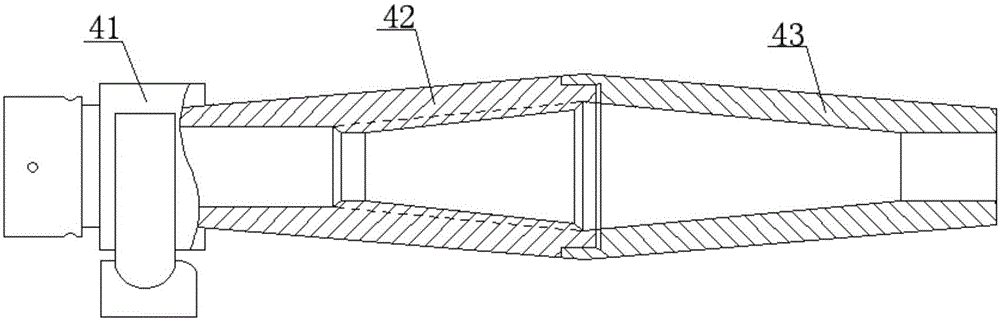

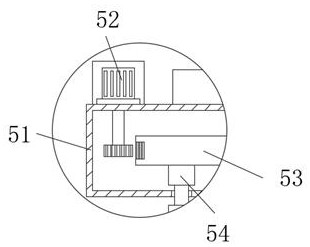

Nozzle for wet-spraying trolley

PendingCN109881893AImprove spraying efficiencyImprove jet qualityUnderground chambersBuilding material handlingEngineeringAxial rotation

The invention provides a nozzle for a wet-spraying trolley. The nozzle comprises a tapered cavity, an inlet part configured to be in a cylinder shape and arranged at the large diameter end of the cavity, a spraying port configured to be in a cylinder shape and arranged at the small-diameter end of the cavity, a plurality of first air inlets and a plurality of second air inlets; and the first air inlets and the second air inlets are circumferentially and evenly formed in the side wall of the inlet part at intervals, and the first air inlets and the second air inlets are arranged at intervals inthe axial direction. A plurality of first rifle line grooves are formed in the inner wall of the cavity, a plurality of second rifle line grooves are formed in the inner wall of the spraying port, the second rifle line grooves are smoothly connected with the first rifle line grooves, and the first rifle line grooves and the second rifle line grooves are configured to enable the compressed gas from the air inlets and the second air inlets to accelerate concrete from the inlet part, axial rotation is generated, and the concrete is evenly sprayed from the nozzle.

Owner:CHINA RAILWAY CONSTR HEAVY IND

An improved push chain type concrete sprayer

InactiveCN104895588BNot easy to cause blockageReduce shockUnderground chambersFoundation engineeringConnection typeSprocket

The invention provides an improved push chain type concrete spraying machine. The improved push chain type concrete spraying machine structurally comprises a frame, a power output assembly, a driving chain wheel, a driven chain wheel assembly, a serial connection type piston assembly, a chain tightener assembly and a piston barrel assembly, wherein the driving chain wheel is connected with a power output shaft of the power output assembly, the driven chain wheel assembly is connected with the chain tightener assembly, the power output assembly and the chain tightener assembly are arranged at the left and right ends of the frame respectively, the piston barrel assembly is arranged above the middle of the frame, and the serial connection type piston assembly winds around the driving chain wheel and the driven chain wheel assembly annularly and passes through the middle of the piston barrel assembly.

Owner:李德安

Injection machine and mechanical arm, injection control method and injection control device thereof

ActiveCN102505853BEasy to controlJet trajectory optimizationUnderground chambersBuilding material handlingControl signalSimulation

Owner:SANY AUTOMOBILE MFG CO LTD

An anti-carbon fuel injection device

ActiveCN110005558BAvoid damageGuaranteed performanceMachines/enginesSpecial fuel injection apparatusCombustion chamberInjector nozzle

Owner:SHANGHAI MICROPOWERS

A closed type washing machine top cover dust removal system

ActiveCN106180074BAvoid enteringImprove uniformityDirt cleaningCleaning using gasesEngineeringInjection air

The invention discloses a closed washing machine top cover plate dedusting system and belongs to the field of dedusting equipment. The closed washing machine top cover plate dedusting system comprises a support mechanism and a cleaning mechanism. The support mechanism comprises a support, a cylinder and an object bearing table. The vertically downward cylinder is installed on a top plate of the support. A pressing plate is connected to a piston rod of the cylinder and matched with the object bearing table to press a workpiece. An air injection mechanism and a lifting mechanism are arranged in the cleaning mechanism. The air injection mechanism mainly comprises an annular air injection pipeline. The lifting mechanism controls the air injection mechanism to move up and down. A dedusting device is connected to the side wall or the top of the support. According to the closed washing machine top cover plate dedusting system, air injection pipes are arranged around the stack of a top cover plate, cleaning treatment is conducted through up-down movement of the air injection pipes, the cleaning efficiency and quality are improved significantly, the workshop environment is improved, and harm to workers is reduced.

Owner:马鞍山甬兴模塑有限公司

A method for removing dust from the top cover plate of a closed washing machine

ActiveCN106111632BAvoid enteringImprove uniformityDirt cleaningCleaning using gasesEngineeringMechanical engineering

The invention discloses a closed-type washing machine top cover plate dedusting method and belongs to the field of dedusting equipment. The dedusting method removes dust through a dedusting system. The dedusting system comprises a supporting mechanism and a cleaning mechanism, wherein the supporting mechanism comprises a support, cylinders and a working stage; the vertically downward cylinders are installed on a top plate of the support; pressure plates are connected to piston rods of the cylinders and used for compressing workpieces; lifting mechanisms are used for controlling jet mechanisms to move up and down; and the side wall or the top of the support is connected with a dedusting device. According to the dedusting method, all faces are subjected to jet processing one by one, dedusting treatment can be conducted while cleaning is conducted, cleaning treatment is conducted through vertical movement of jet pipes, the cleaning efficiency and quality are remarkably improved, the workshop environment is improved, and injuries to workers is reduced.

Owner:马鞍山甬兴模塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com