Nozzle for wet-spraying trolley

A nozzle and trolley technology, which is applied in the processing of building materials, wellbore lining, tunnel lining, etc., can solve problems affecting the safety of equipment and operators, increase injection resistance, and hold back explosions, so as to improve injection construction efficiency and avoid blockages. situation, the effect of improving the injection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is introduced below by accompanying drawing.

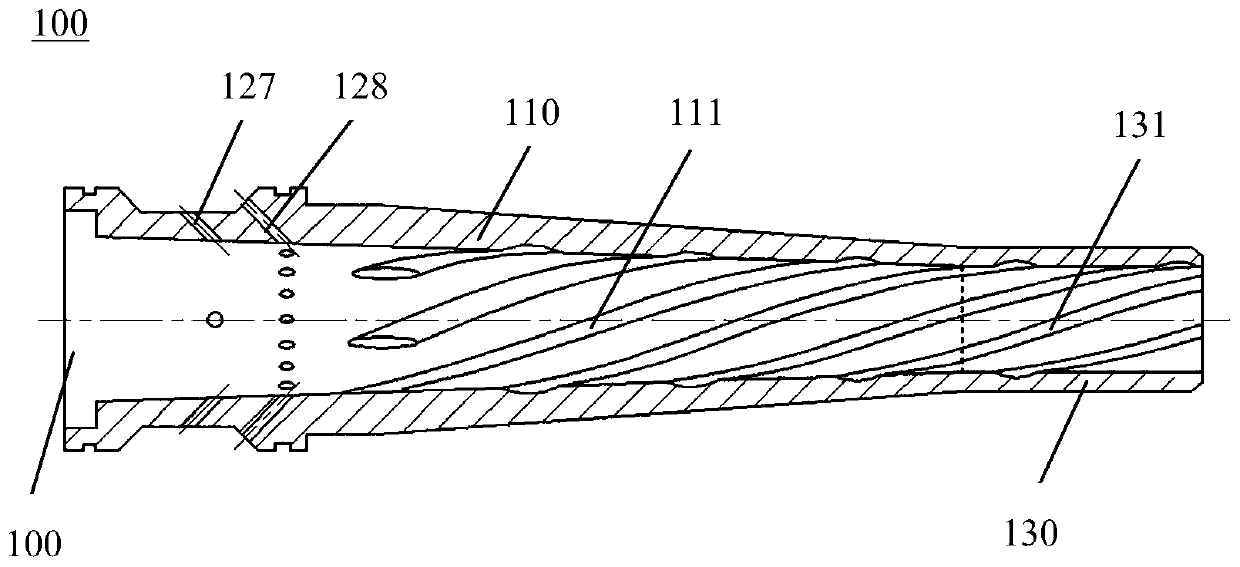

[0022] It should be noted that the terms "axial" and "radial" in this article refer to figure 1 in the horizontal and vertical directions.

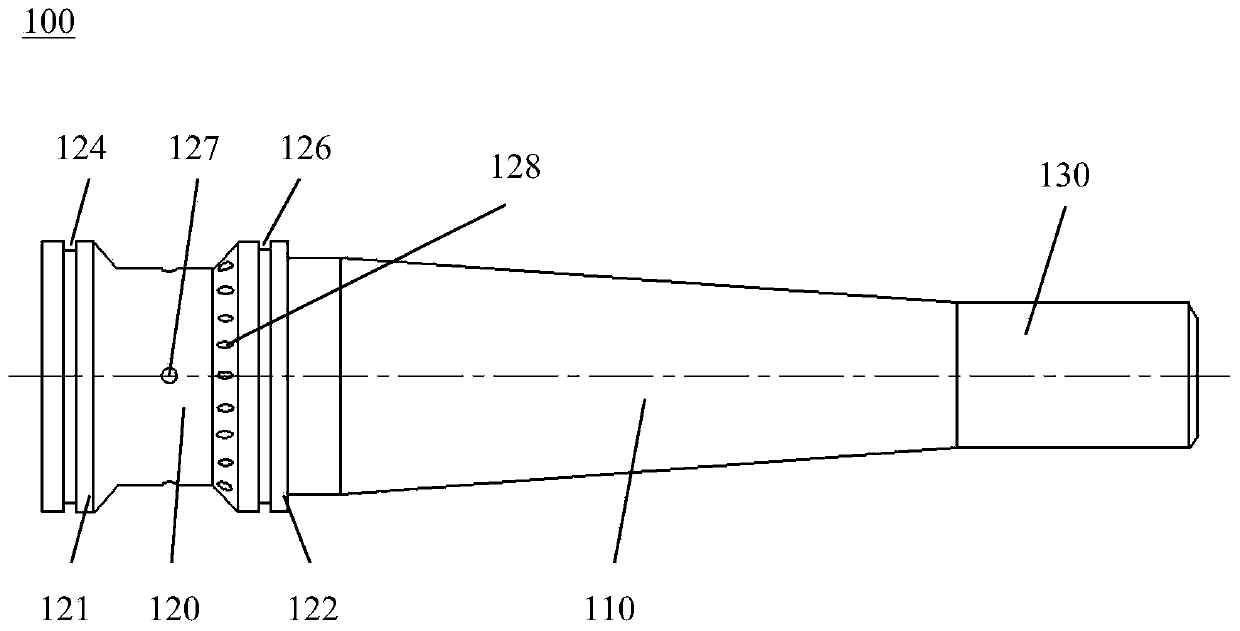

[0023] figure 1 The three-dimensional structure of the nozzle 100 for the wet spray trolley according to the present invention is schematically shown. The nozzle 100 is especially suitable for spraying concrete with a wet spray trolley.

[0024] Such as figure 1 As shown, the nozzle 100 includes a cavity 110 . The cavity 110 is configured as a cone, and an inlet portion 120 is provided on the axially outer side of the large diameter end of the cavity 110, and the inlet portion 120 is configured as a hollow cylinder. The inlet portion 120 is used to connect with the concrete supply pipeline of the wet spray trolley. Meanwhile, the small-diameter end of the cavity 110 is configured as an outlet end. The structure of the cavity 110 is beneficial to increase th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com