Shaftless spiral material mixing, stirring and feeding machine

A shaftless screw and feeder technology, which is applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of serious adhesion, time-consuming and labor-intensive, and reduced efficiency, and achieve convenient movement, improved spray quality, and efficient mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

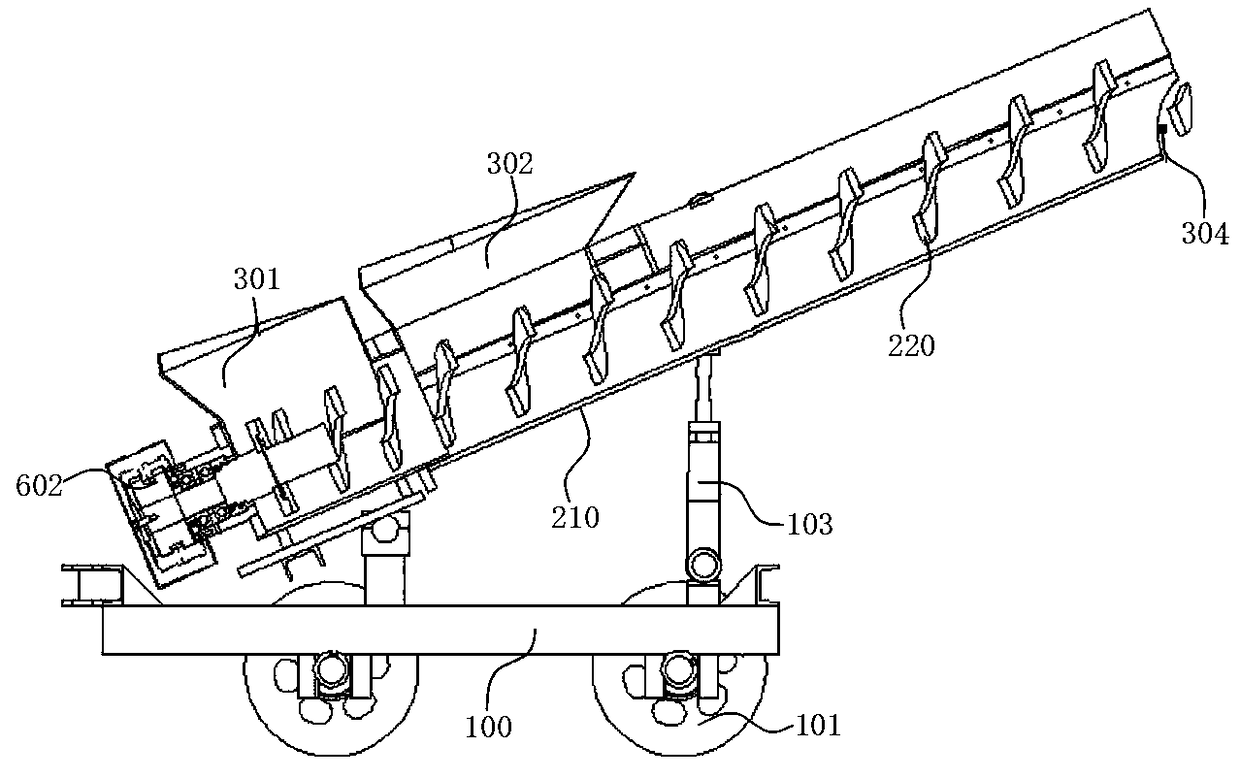

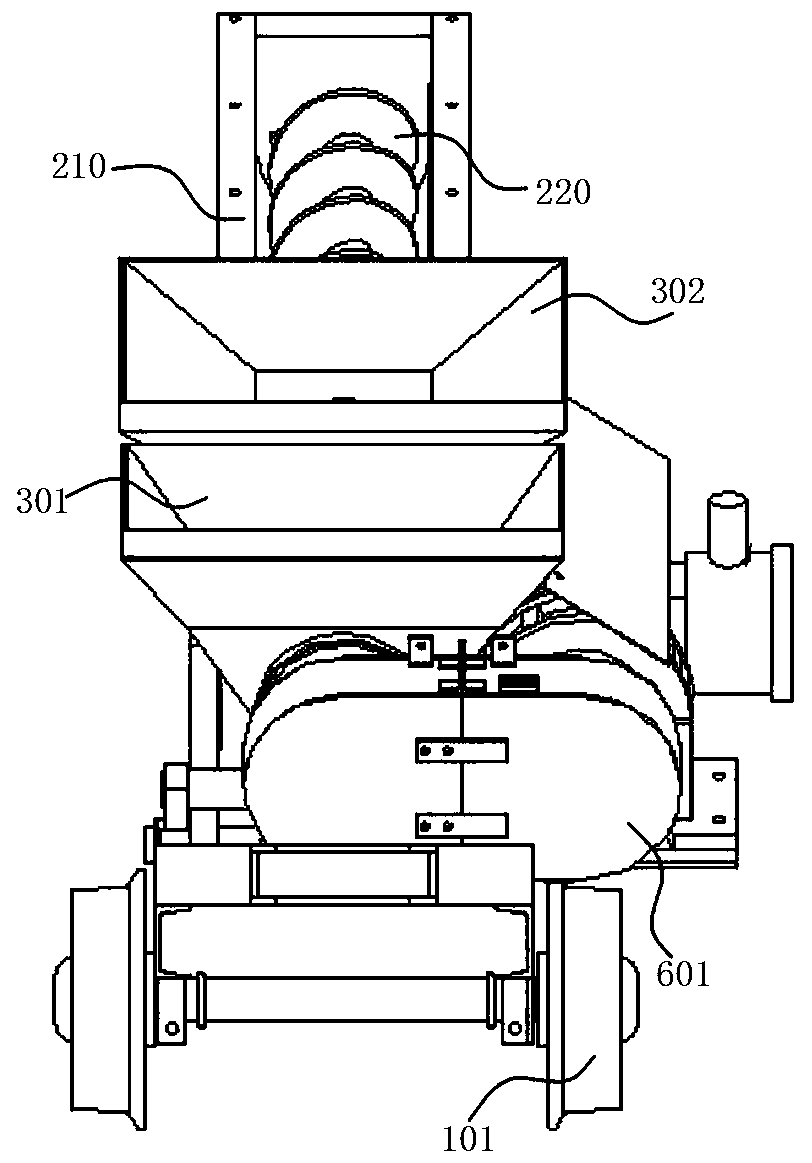

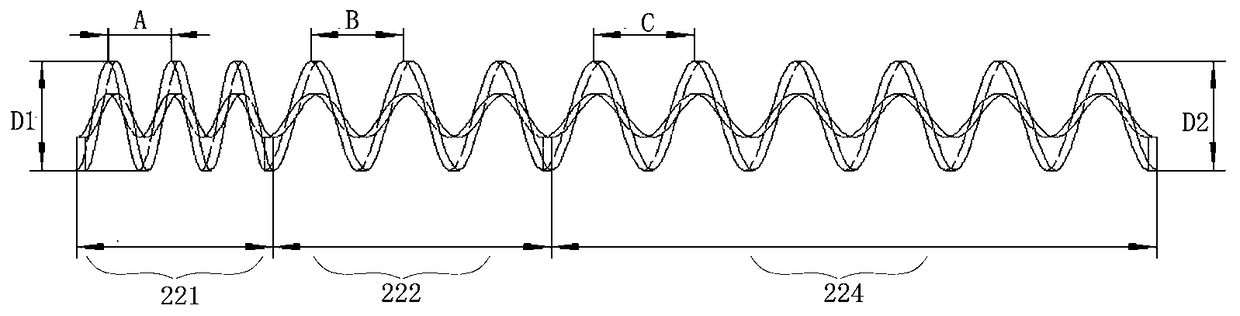

[0033] see Figure 1-Figure 6 , a shaftless screw batching and feeding machine for this application, including a base 100, a main stirring shell 210, a main shaftless screw 220 and a power assembly, the main stirring shell 210 is in the shape of a U-shaped groove, and the main stirring shell 210 supports It is arranged on the base 100, and a plurality of upper material bins are arranged on the main stirring shell 210, and the upper material bins at least include a first upper material bin 301 and a second upper material bin 302. The end of the stirring shell 210 is provided with a discharge port 304; the main shaftless screw 220 is matched in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com