Flocking machine

A flocking machine and flocking technology, applied in the field of flocking machines, can solve problems such as affecting output and work efficiency, harming the body, and being easily inhaled by people, and achieve the effect of eliminating fluff flying and eliminating blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

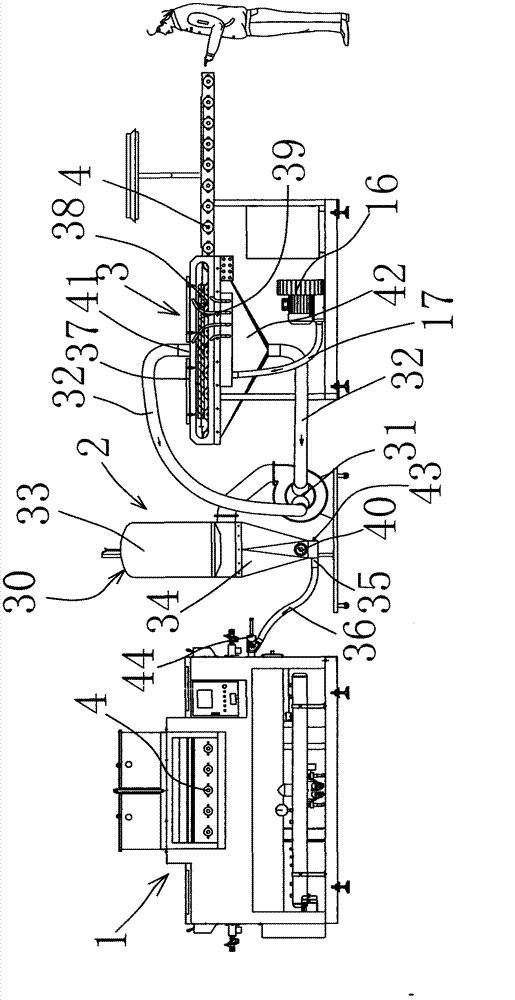

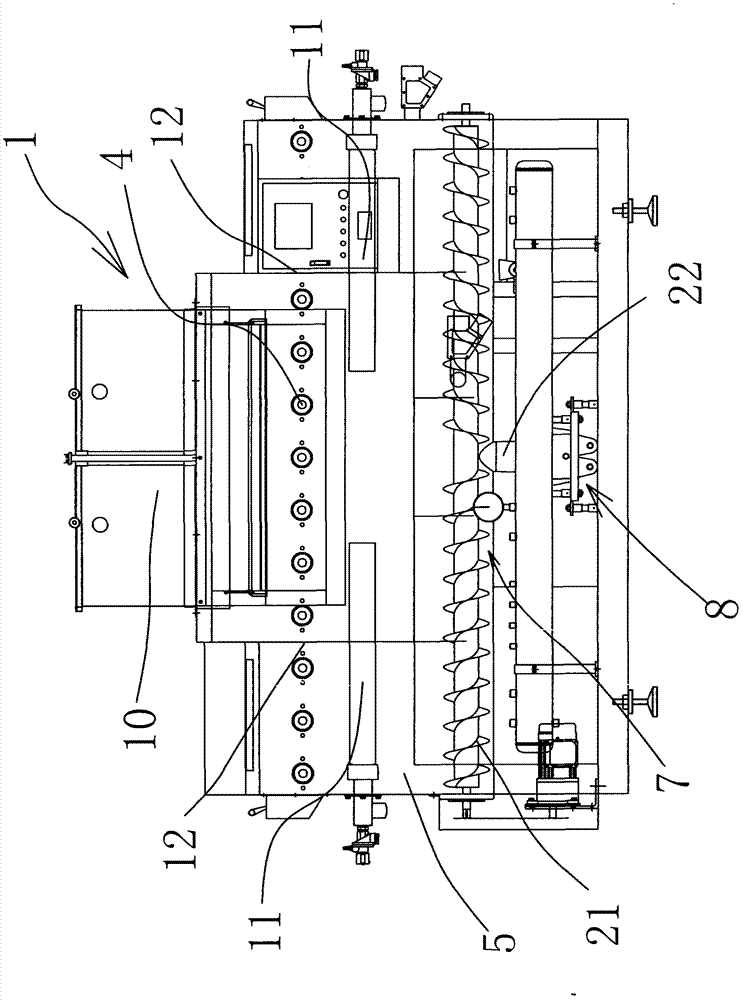

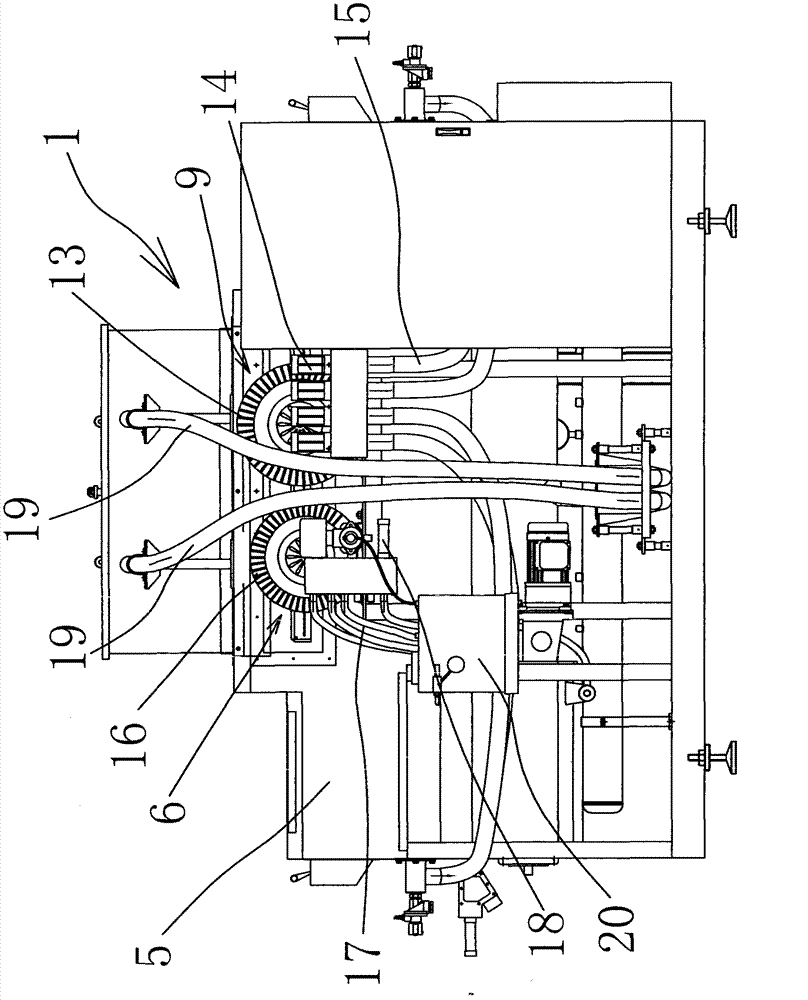

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] In the figure, flocking equipment 1; fluff recycling equipment 2; fluff blowing equipment 3; conveying roller 4; body 5; fleece blowing mechanism 6; fluff conveying mechanism 7; fluff filtering mechanism 8; Chamber 10; suction filter bag 11; isolation damping baffle 12; negative pressure fan 13; negative pressure control cylinder 14; negative pressure suction pipe 15; velvet blower 16; Fleece tube 19; humidifying water tank 20; conveying screw 21; flexible connecting pipe 22; vibrating box 23; flexible connecting interface 24; first injection and suction chamber 25; filter screen 26; accommodation space 27; Space 27b; the first velvet blowing air pipe connection 28; the second velvet blowing air pipe interface 29; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com