Turning, closing-up and rib rolling device for tube parts

A technology for parts and turning, which is applied in the field of beading and beading devices for pipe parts, can solve the problems of beading and beading devices for turning, complex mold structure, long processing cycle, etc., and achieves simple clamping, short processing cycle, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

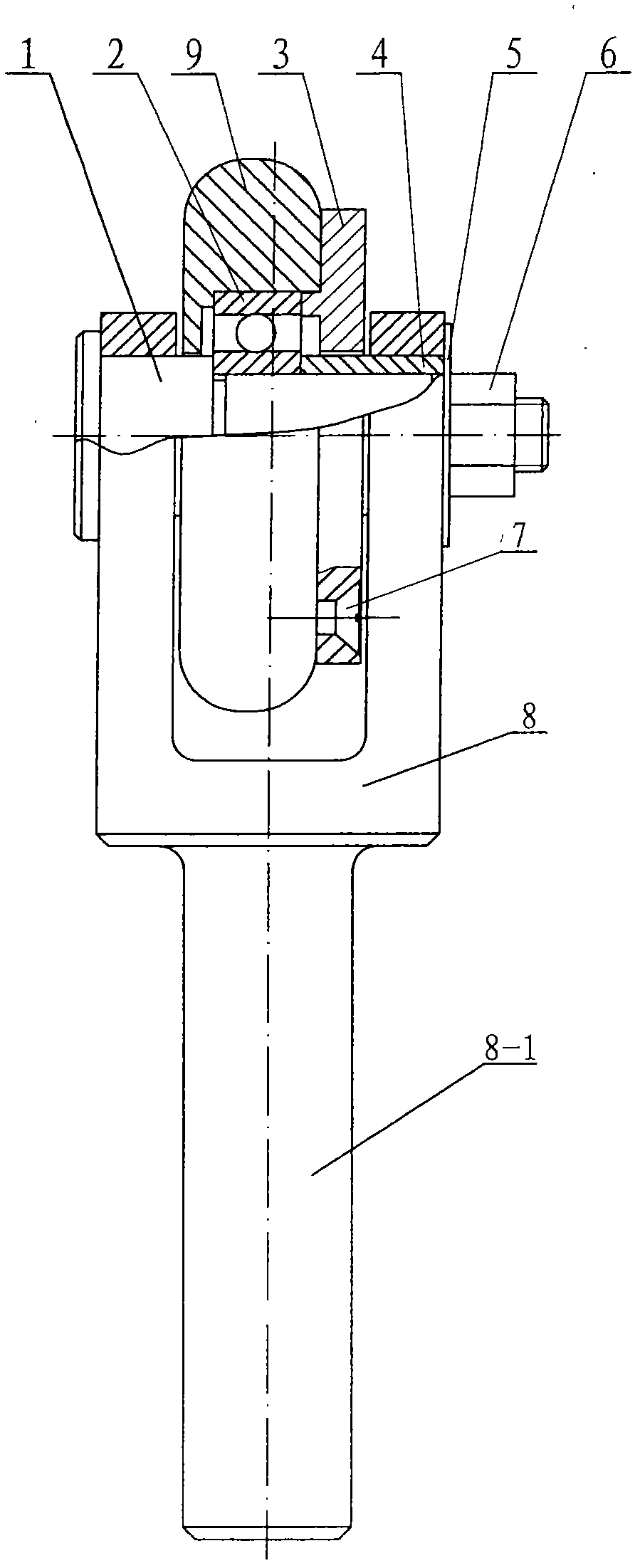

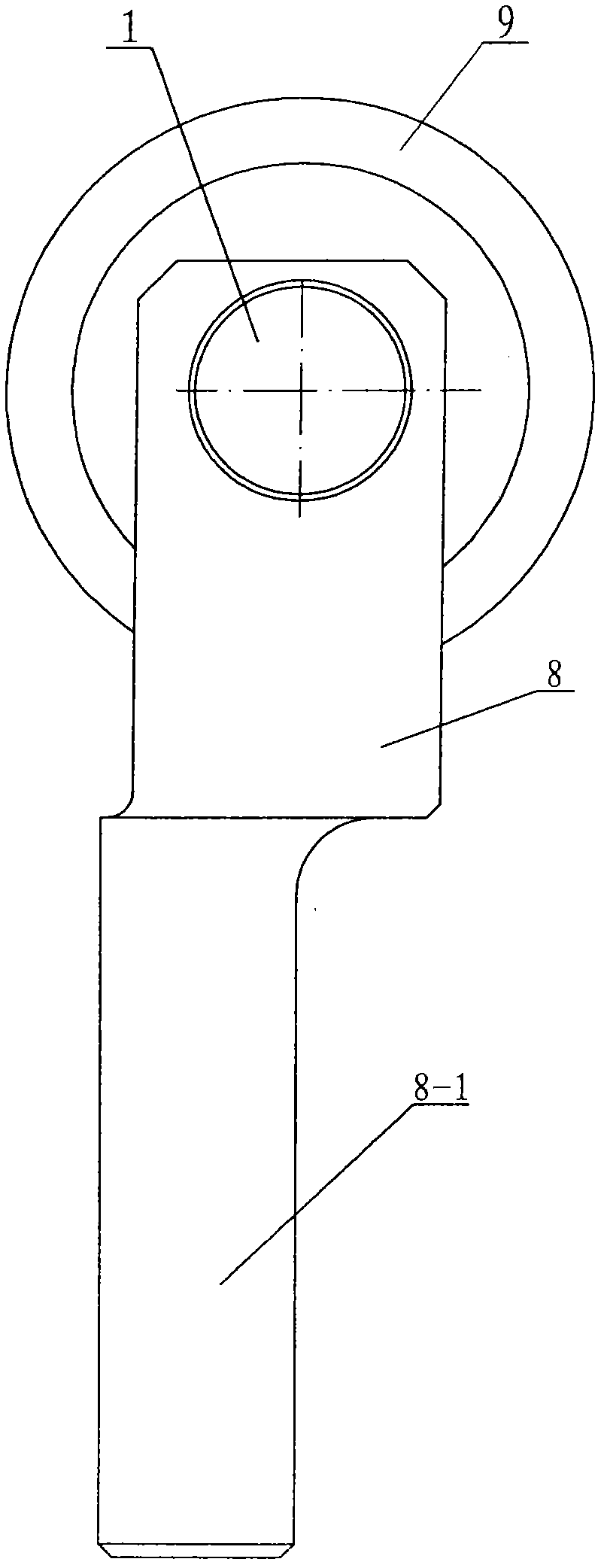

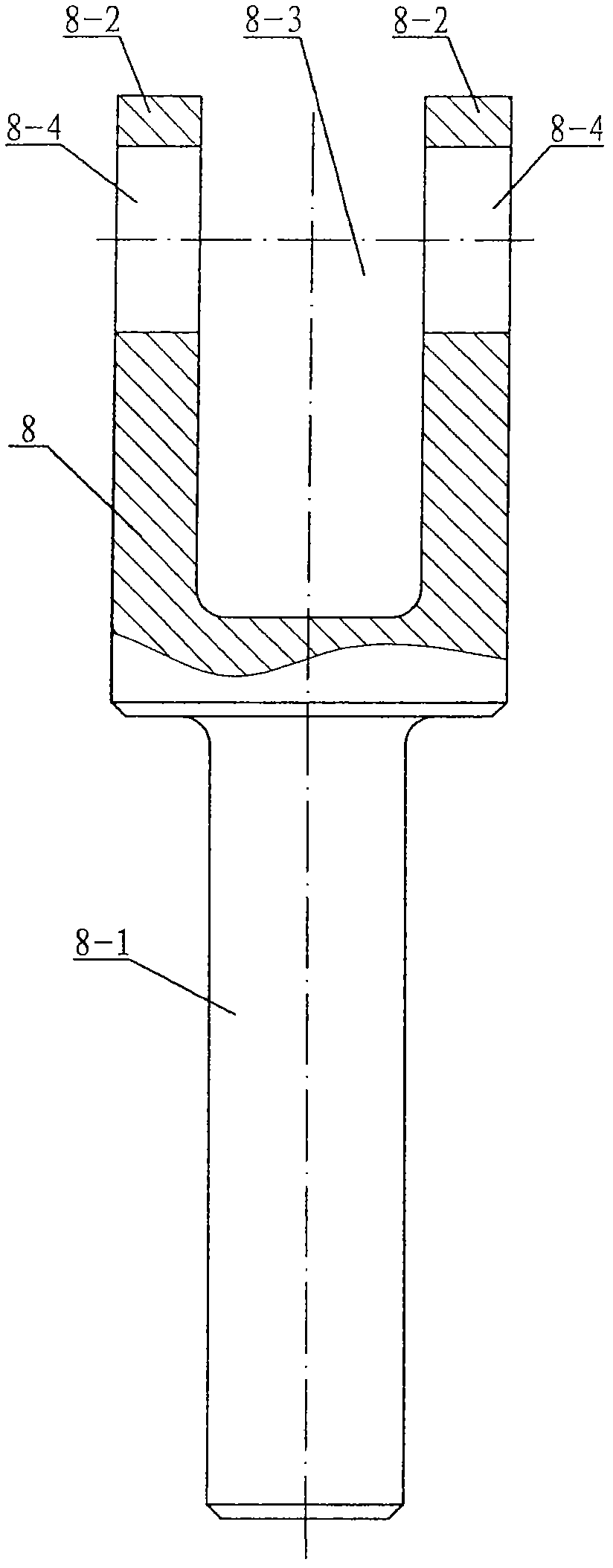

[0007] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes shaft 1, bearing 2, pressure ring 3, limit sleeve 4, washer 5, nut 6, roller frame 8, roller 9 and three screws 7, the axis of roller 9 is provided with The stepped hole, the stepped through hole is the bearing installation hole 9-1, the transition hole 9-2 and the inner hole of the roller 9-3. From the axial section of the roller 9, the outer surface of the roller 9 is an outwardly convex arc Surface 9-4, the bearing 2 is set in the bearing installation hole 9-1, the outer surface of the pressure ring 3 is a stepped cylinder, the stepped cylinder is respectively the compression section 3-1 and the connection section 3-2, and the axis of the pressure ring 3 There is a through hole 3-3 at the connecting section 3-2, and three countersunk nail holes 3-4 are evenly distributed on the connecting section 3-2. The pressing section 3-1 is arranged in the bearing i...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination image 3 and Figure 4 The present embodiment will be described. The cross-section of the clamping portion 8-1 of the present embodiment is a rectangle. During use, the clamping part 8-1 is clamped on the tool rest of the lathe, and the section of the clamping part 8-1 is designed as a rectangle for easy clamping. Other components and connections are the same as those in the first embodiment.

[0009] The working process of the present invention: according to the different dimensions of the outer diameter, ordinary lathes of different specifications are selected in the closing processing, the processing parts (pipe parts) are clamped on the lathe chuck, and clamped after alignment; the pipe parts The clamping part 8-1 on the turning closing and rolling device is clamped on the lathe tool holder, the axis line of the roller 9 is perpendicular to the axis line of the lathe main shaft, and the position of the turning closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com