Small drilling machine

A drilling machine, a small-scale technology, applied in the field of machine tools, can solve the problems of easy operation accidents caused by students, complicated operation of automatic drilling machines, etc., and achieve the effects of easy clamping, reduced labor intensity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

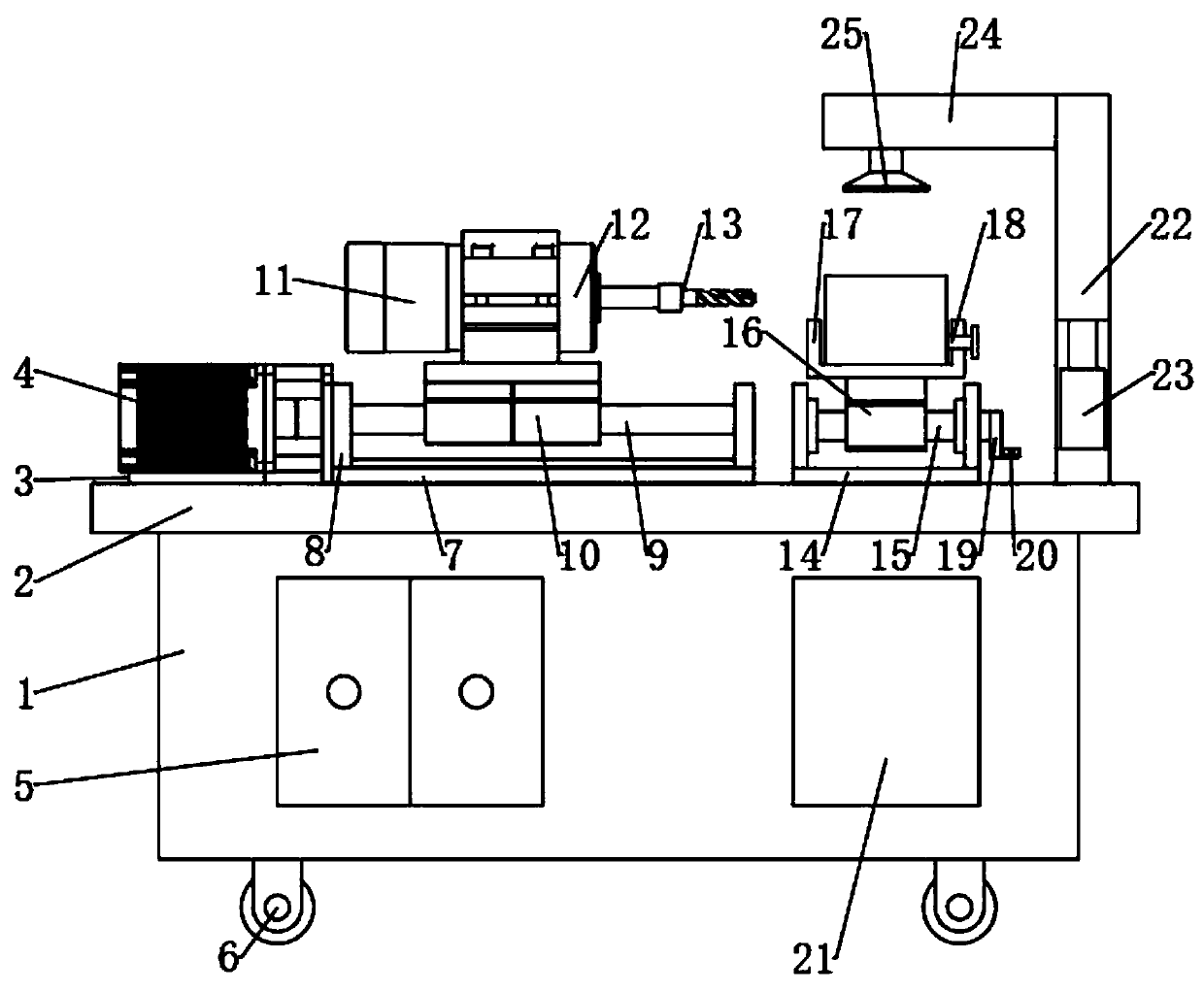

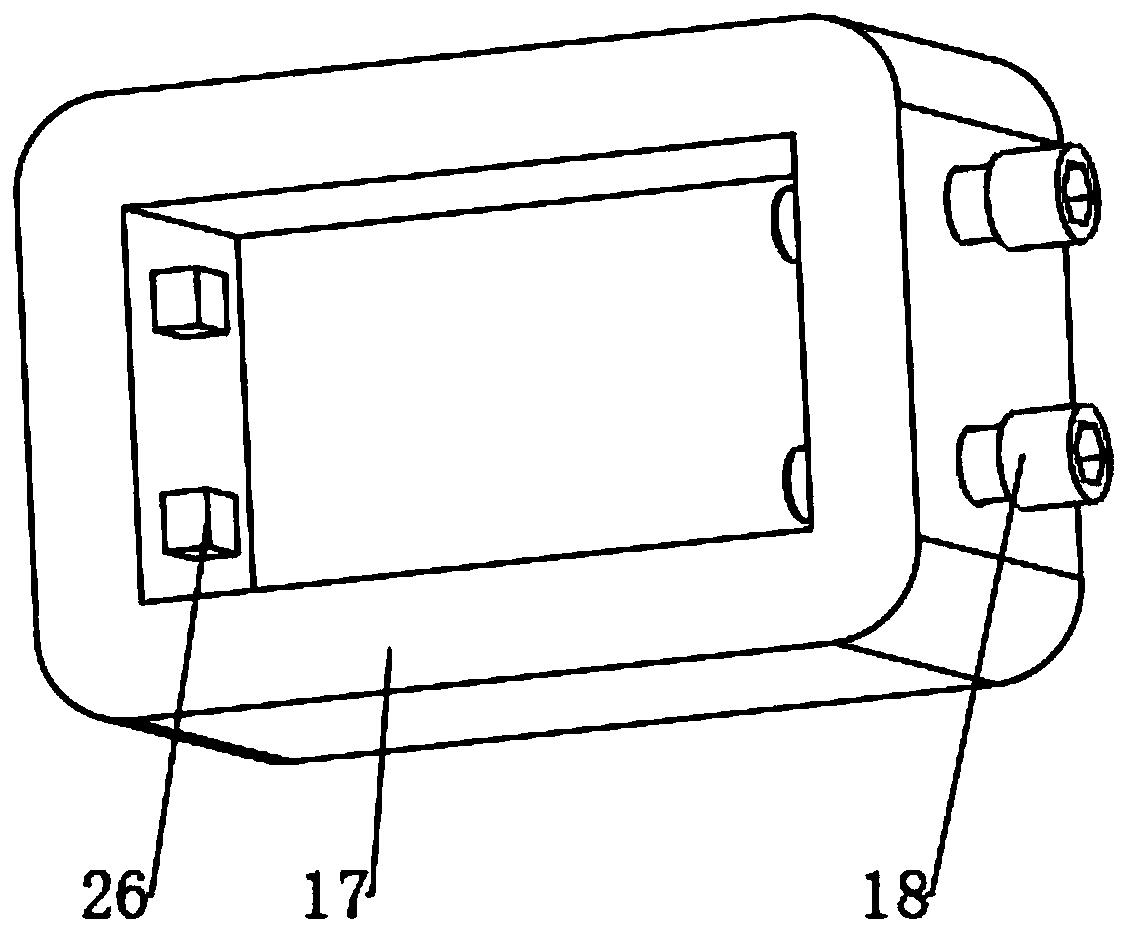

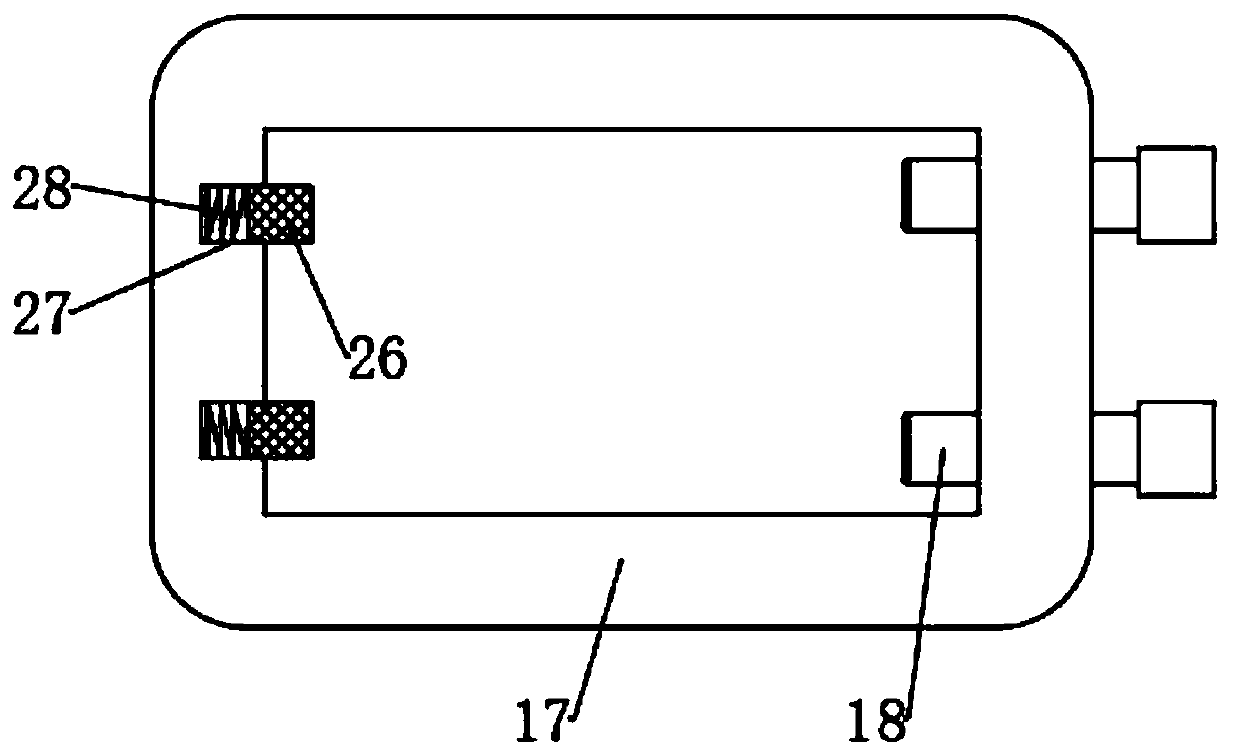

[0020] see Figure 1-3 , a small drilling machine, comprising a body 1, a workbench 2 is arranged on the upper surface of the body 1, a feed mechanism and a fixture are arranged at intervals on the workbench 2, a workpiece is installed in the fixture, and the feed mechanism includes a fixing seat 7, The fixed seat 7 is fixedly connected to the upper end surface of the workbench 2. The section of the fixed seat 7 is U-shaped. The fixed seat 7 is equipped with a feed screw 9 through a fixed bearing 8. The feed screw 9 is equipped with a feed block 10 , the feed block 10 is connected to the feed screw 9 in transmission, and the upper end side of the feed block 10 is fixedly connected with a tool holder 12, and a cutter 13 is installed in the cutter holder 12, and the cutter 13 is connected with a drilling motor 11 through transmission, and the drilling The motor 11 is located on one side of the tool holder 12 and is fixedly connected with the feed block 10; one end of the feed sc...

Embodiment 2

[0030] In Embodiment 1, the body 1 is placed on the ground and it is inconvenient to move. Therefore, this embodiment is improved on the basis of Embodiment 1. The improvement is: a universal wheel 6 that is easy to move is arranged under the body 1, Save labor when moving the machine tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com