End enclosure spinning backward-overturning preventing device

A technology of anti-material and pressure wheel, which is applied in the field of spinning manufacturing, can solve the problems of large consumption of copper block, easy involvement of copper shavings in the sheet material to affect the surface quality of the head, and poor effect of anti-material backturning, etc., to achieve stable operation Reliable, material-proof flip-back function is obvious, and the installation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

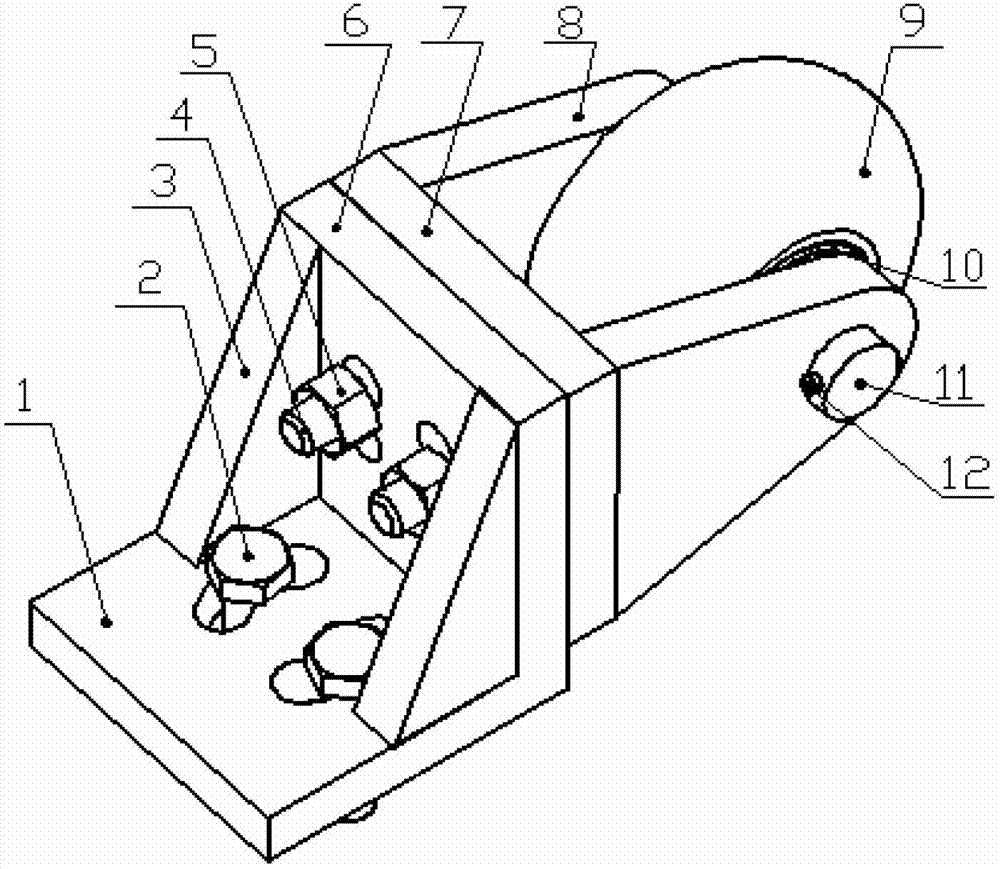

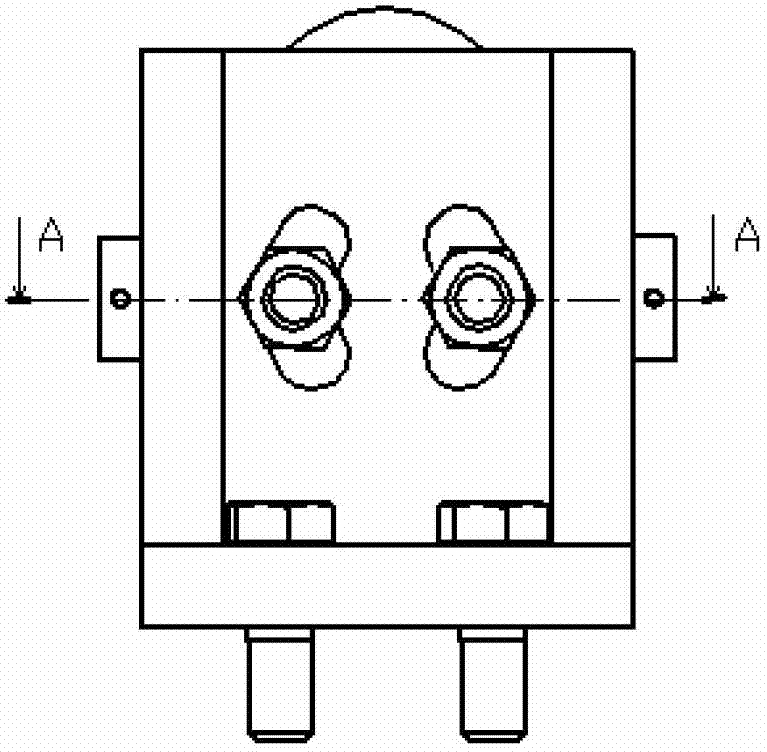

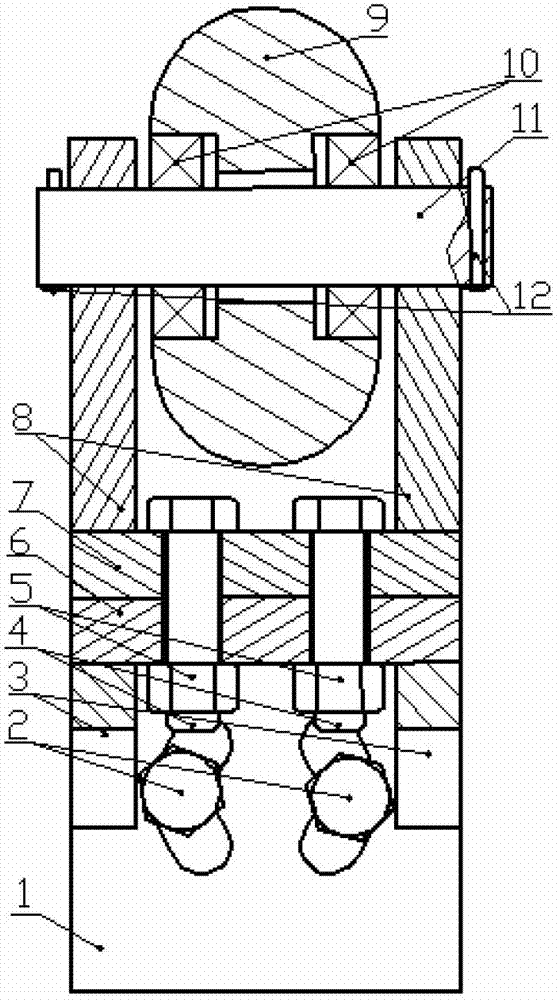

[0020] This embodiment is an anti-rollback device for spinning heads with a diameter of φ2200mm, a wall thickness of 3mm, and an ellipsoidal inner surface, including an adjustment frame, a pressing wheel bracket 8 and a pressing wheel 9 .

[0021] The adjustment frame includes a horizontal adjustment plate 1, a vertical adjustment plate 6 and two adjustment screw rods 2, the vertical adjustment plate 6 is located at one end of the upper surface of the horizontal adjustment plate 1, and is at right angles to the horizontal adjustment plate 1; between the vertical adjustment plate 6 There is a pair of supporting ribs 3 between the horizontal adjustment plate 1. There is a pair of arc-shaped adjustment grooves on the vertical adjustment plate 6 , the adjustment grooves pass through the vertical adjustment plate 6 , and the concave arc surfaces of the pair of arc-shaped adjustment grooves correspond to each other. There is also a pair of arc-shaped adjustment grooves on the level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com