Clamp for processing positioning hole on engine cylinder cover

A technology for engine cylinder heads and positioning holes, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of complex structure of engine cylinder heads, influence of cylinder head processing efficiency, low efficiency of tooling clamping, etc., and achieve simple structure , controllable strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

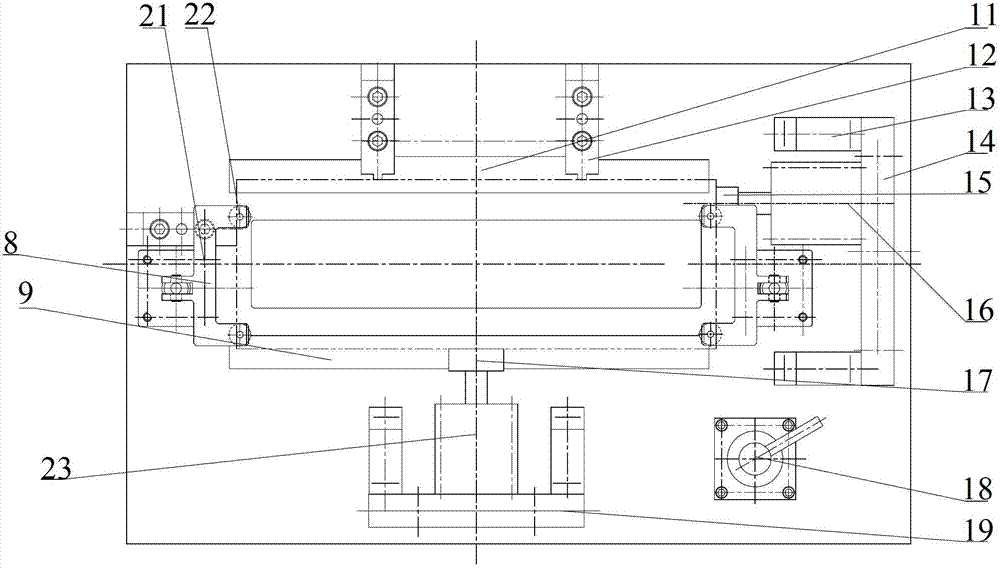

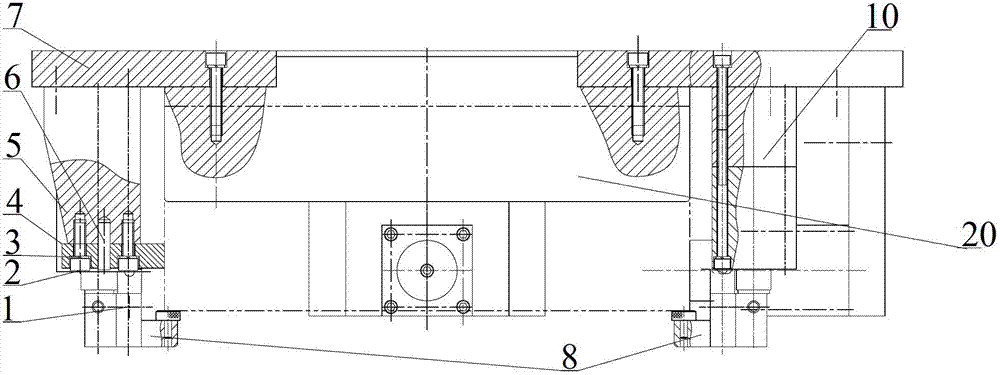

[0019] Such as figure 1 and figure 2 As shown, the horizontal clamping mechanism of the fixture includes an air intake surface support 11 for positioning the air intake surface of the cylinder head 20, an end face support 5 for positioning one end face of the cylinder head 20, and compresses the cylinder head on the other end face of the cylinder head 20. The end face air cylinder 16 of 20 and the exhaust face air cylinder 23 of compressing the cylinder head 20 on the cylinder head 20 exhaust face, the intake face support 11, the end face support 5, the end face air cylinder 16 and the exhaust face air cylinder 23 are fixed on On the base plate 7 , the end face air cylinder 16 and the exhaust face air cylinder 23 are controlled by the air cylinder control device 18 arranged on the base plate 7 . The end face pneumatic cylinder 16 cooperates with the end face support 5 to clamp the cylinder head 20 in one direction of the horizontal plane, and the exhaust face pneumatic cylin...

Embodiment 2

[0022] Such as figure 1 and figure 2 As shown, the intake surface support 11 of the horizontal clamping mechanism is a support plate with the same height as the cylinder head 20 intake surface boss, and the intake surface of the cylinder head 20 is close to the positioning surface of the intake surface support 11 , the positioning surface of the intake surface support 11 will be polished smooth, and the intake surface support 11 is supported and fixed by two intake surface positioning blocks 12 fixed on the base plate 7, and the intake surface support 11 defines a cylinder head 20 Horizontal degrees of freedom.

Embodiment 3

[0024] Such as figure 1 and figure 2 As shown, the end surface support 5 of the horizontal clamping mechanism is positioned against the end surface of the cylinder head 20 by the end surface positioning block 4 arranged thereon, and the positioning surface of one end of the end surface positioning block 4 abuts against the end surface of the cylinder head 20 , the other end is fixed on the end face support 5 by screws 2 (with washers 3 ) and circular positioning pins 6 , the end face positioning block 4 is fastened on the bottom plate 7 , and the end face support 5 defines another horizontal degree of freedom of the cylinder head 20 . The positioning surface of the end face positioning block 4 will be polished smoothly to ensure that the flatness of the positioning surface meets the technical requirements and ensure reliable positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com