Large-opening shape-preserving device used for large-scale airplane assembly

A technology of aircraft assembly and large opening, which is applied in aircraft assembly, aircraft parts, ground devices, etc., to achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

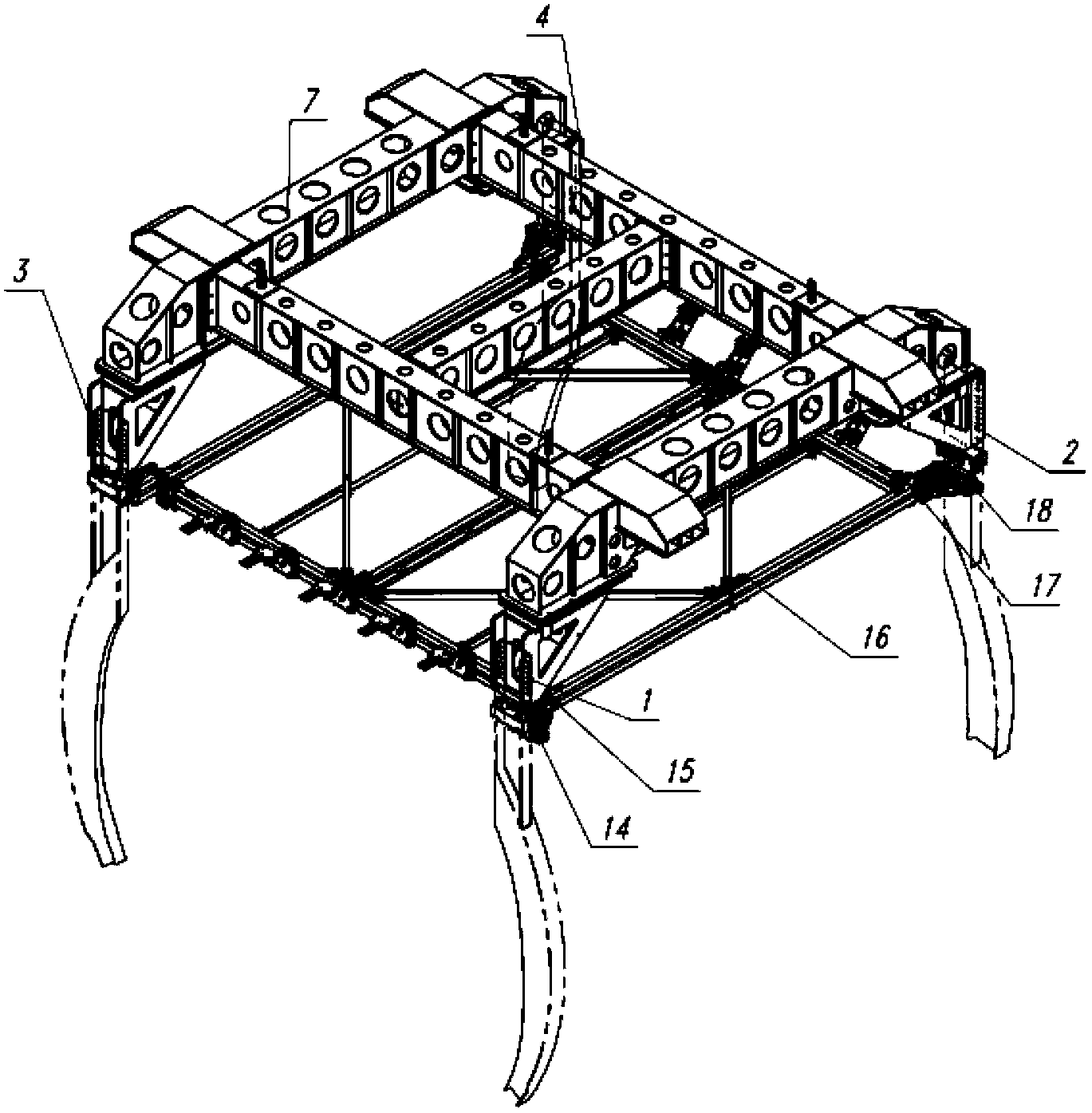

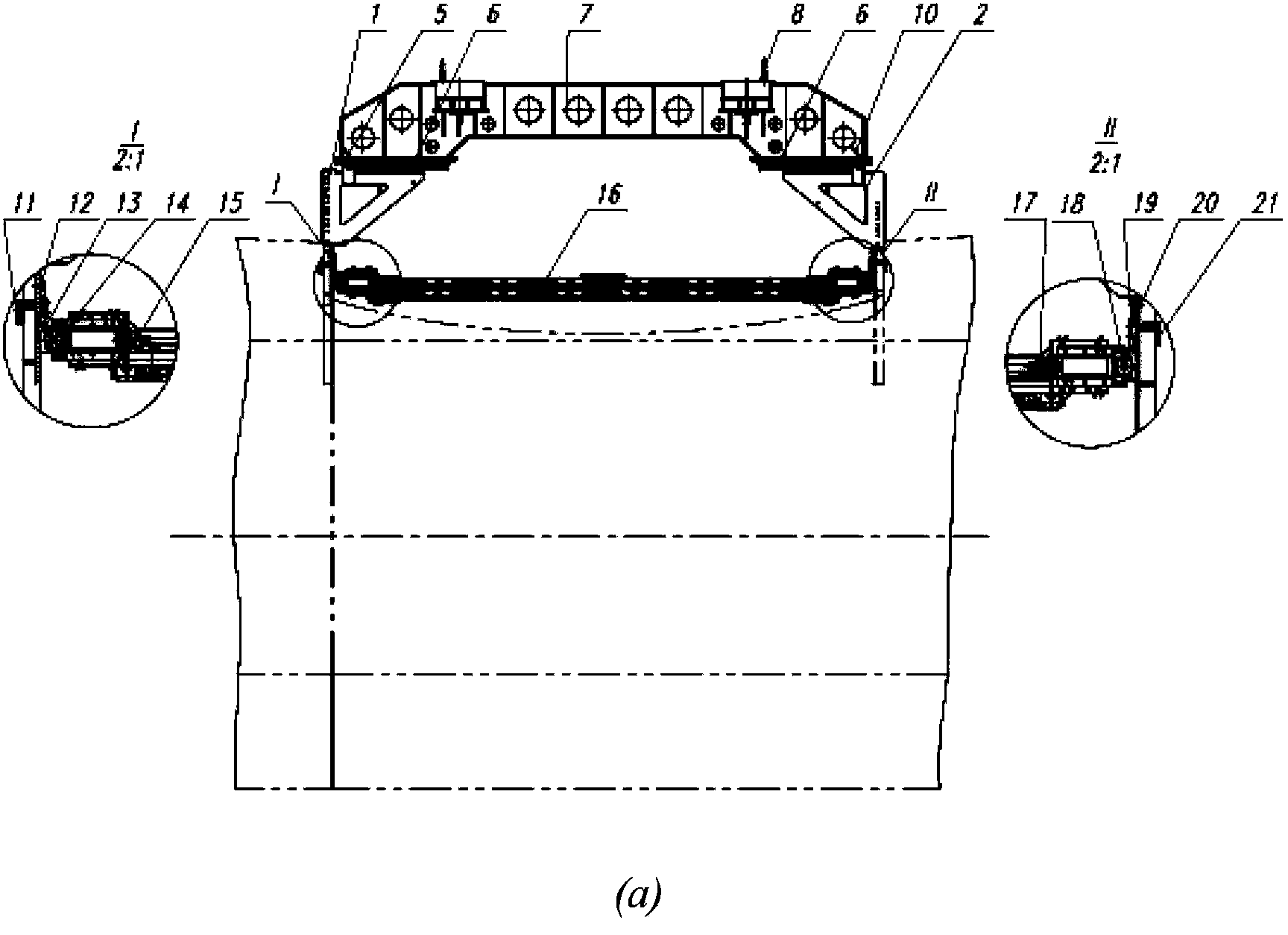

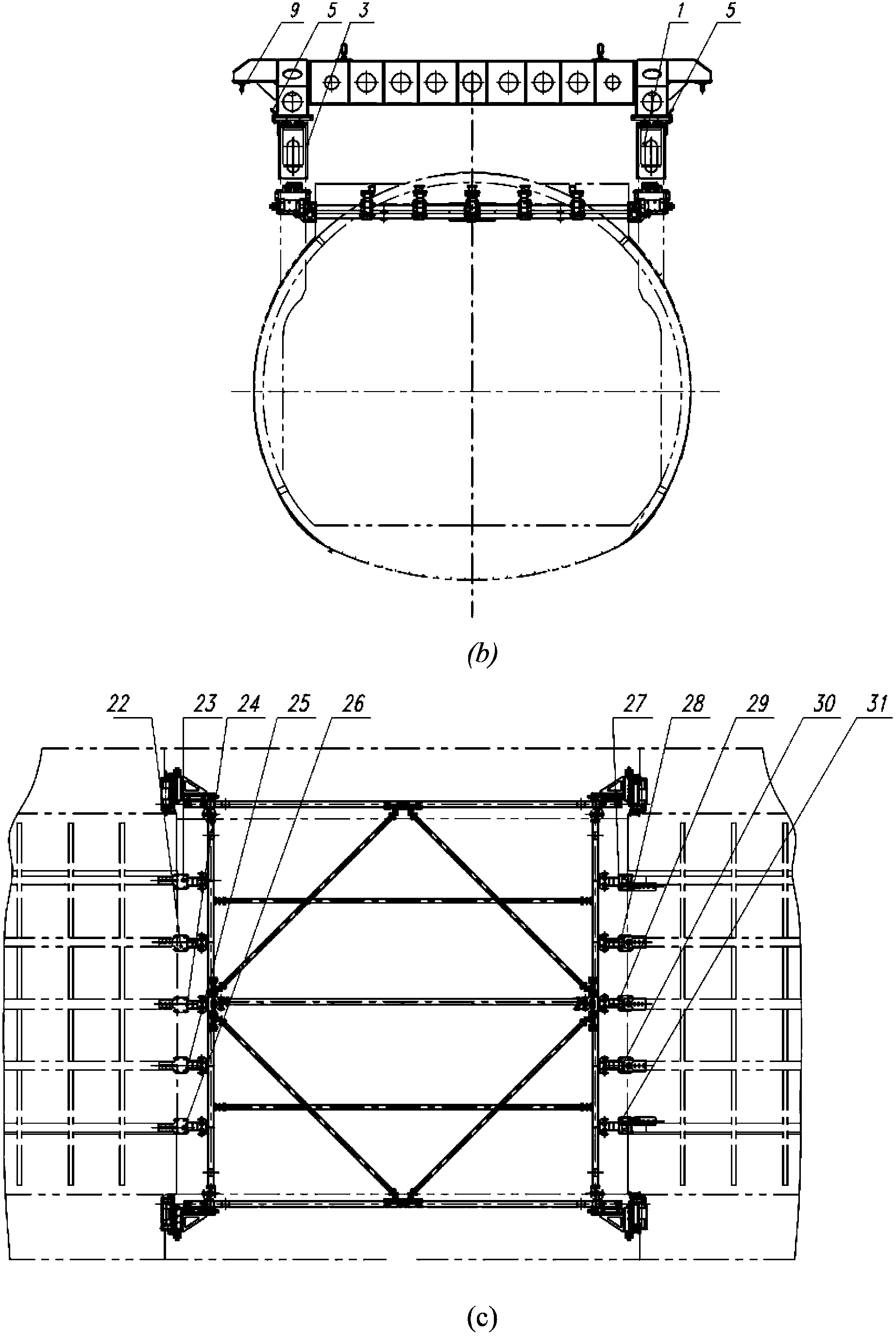

[0020] As shown in 1, 2, 3, and 4 accompanying drawings, the large-opening shape-preserving device used for large-scale aircraft assembly includes an upper-level shape-keeping frame and a lower-level shape-keeping frame.

[0021] The upper layer retaining frame includes the first positioning joint 1, the second positioning joint 2, the third positioning joint 3, the fourth positioning joint 4, the first positioning pin 5, the guide rail 6, the upper layer retaining frame 7, the lifting ring 8, four process Ball head 9, second positioning pin 10.

[0022] The first locating joint 1, the second locating joint 2, the third locating joint 3, and the fourth locating joint 4 are respectively connected with the slide block of the guide rail 6 installed on the upper layer shape-preserving frame 7, and move along the course, and pass through the first positioning pin 5. The second positioning pin 10 is used for positioning, and two suspension rings 8 and four technical ball heads 9 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com