Electrode foil conveyer and laminated cell manufacturing device

A technology for transporting devices and stacked batteries, which is applied in the directions of electrode manufacturing, transportation and packaging, and final product manufacturing to achieve the effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

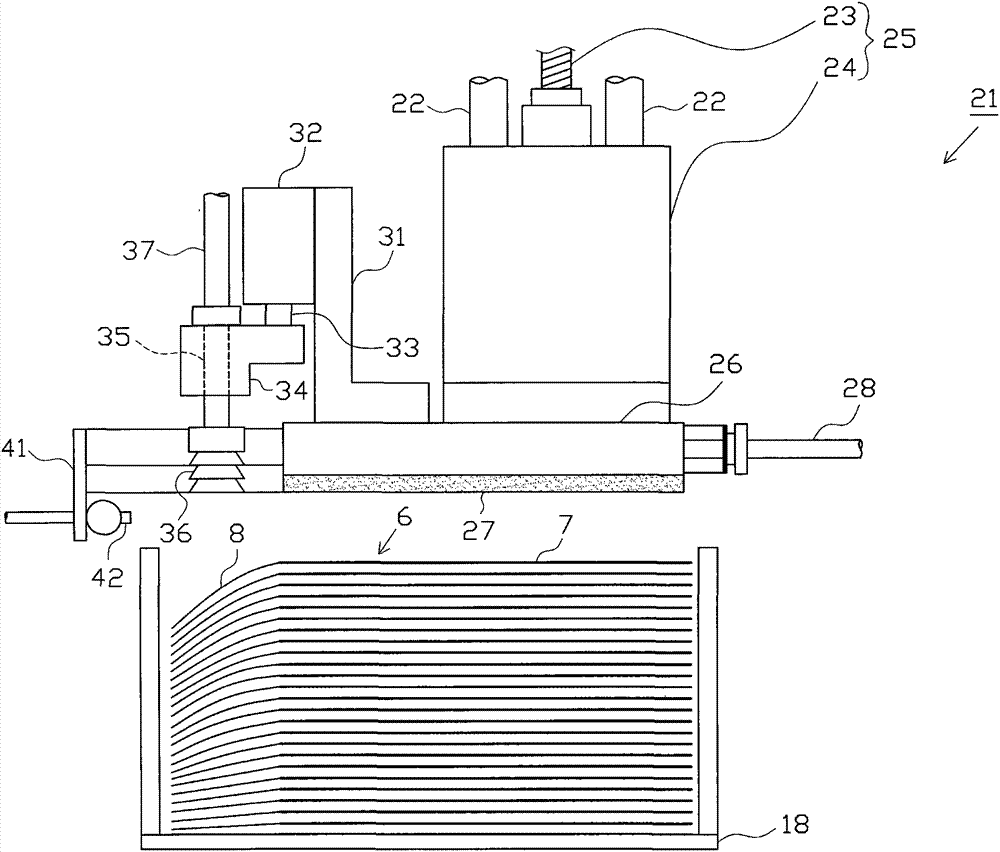

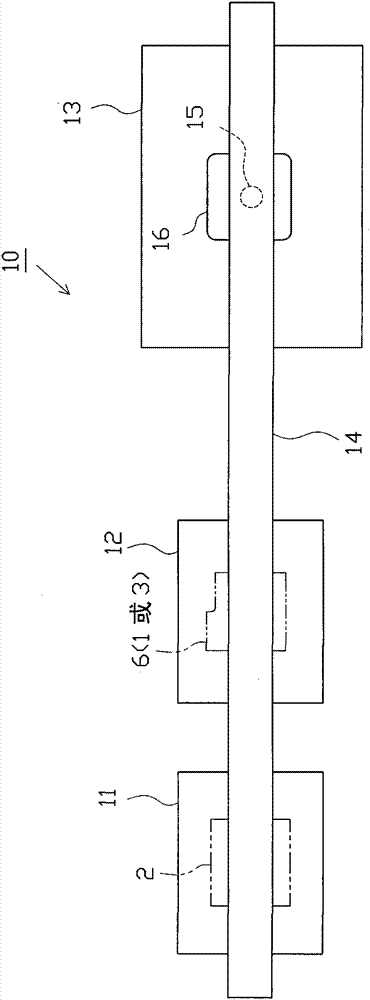

[0058] An embodiment will be described below with reference to the drawings.

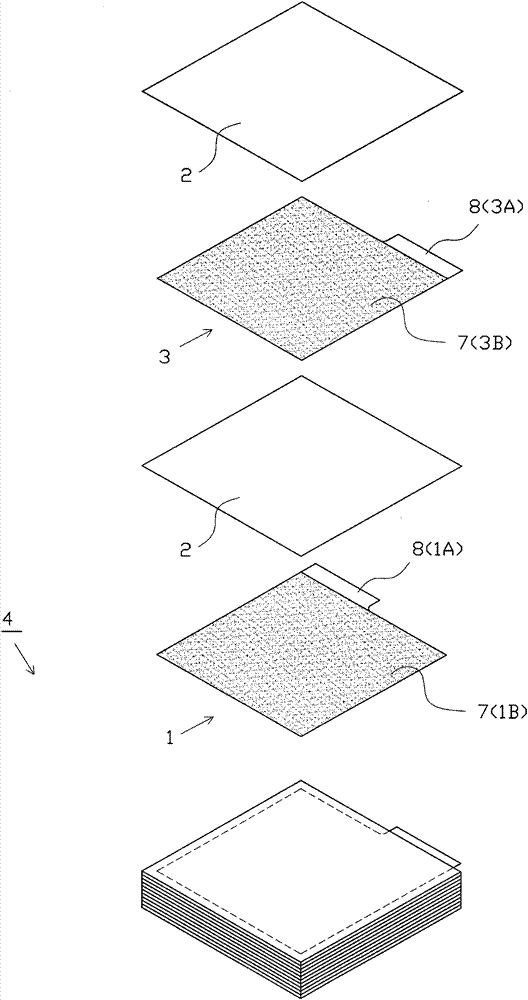

[0059] Such as image 3 As shown, in the laminated body 4 that constitutes the laminated battery, in order from the bottom, the negative electrode foil 1, the separator 2, the positive electrode foil 3, and the separator 2 are repeatedly stacked and stacked (of course, the positive electrode foil can also be stacked). Foil 3 is located on the bottommost layer, on which separator 2, negative electrode foil 1, separator 2, positive electrode foil 3, ... are stacked in this order). As shown in Fig. 4 (a) and Fig. 4 (b), both the negative electrode foil 1 and the positive electrode foil 3 are composed of a planar rectangular part and a protruding part protruding from a part thereof, including an electrode foil main body 1A formed by a metal foil, 3A and the active materials 1B, 3B formed on the inner and outer surfaces of the electrode foil main bodies 1A, 3A are coated. In addition, the electrode foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com