Electrodeless adjusting and aligning device of welded nets

A technology of welding mesh and adjusting alignment, which is applied in the direction of stacking receiving device, transportation and packaging, thin material processing, etc., can solve the problems that cannot meet the production needs and market, and cannot adapt to welded mesh, so as to meet the production needs and The effect of market demand, simple and convenient adjustment, and high adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are further described in detail below.

[0019] It should be noted that when the components in the structure of the present invention are the same as those in the prior art, the same serial numbers are used for the same components.

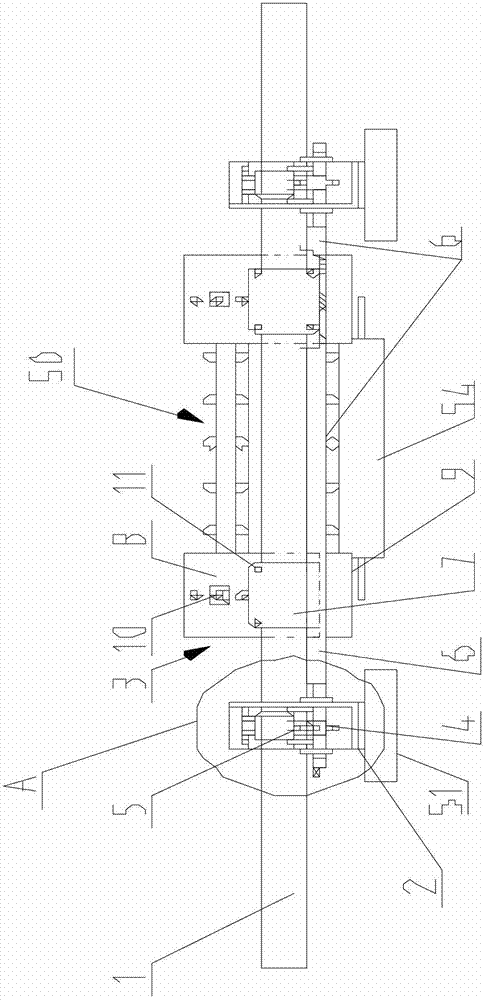

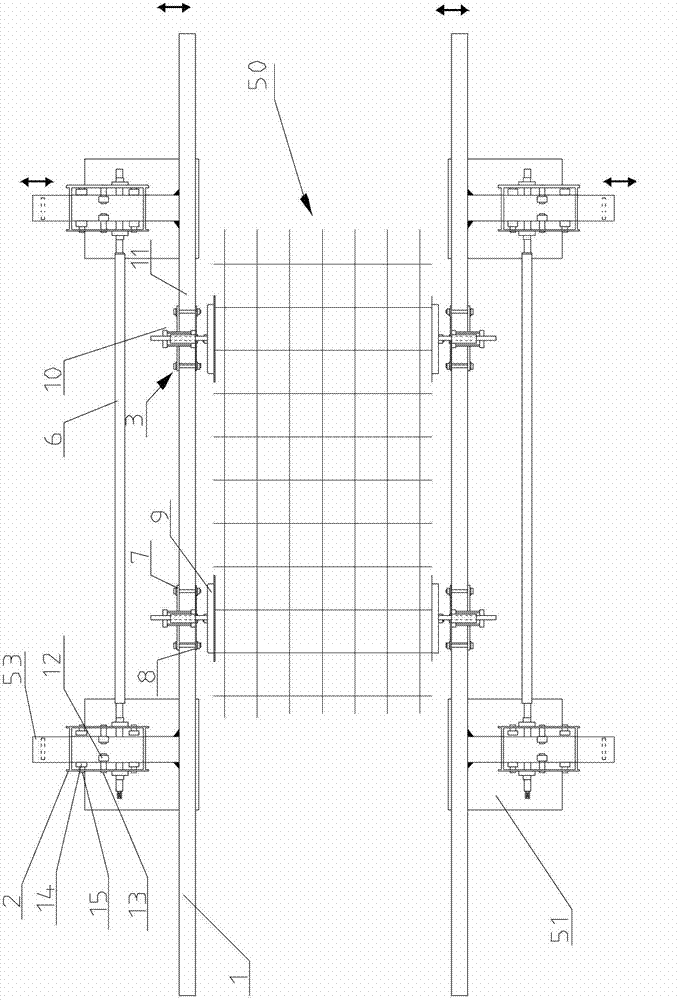

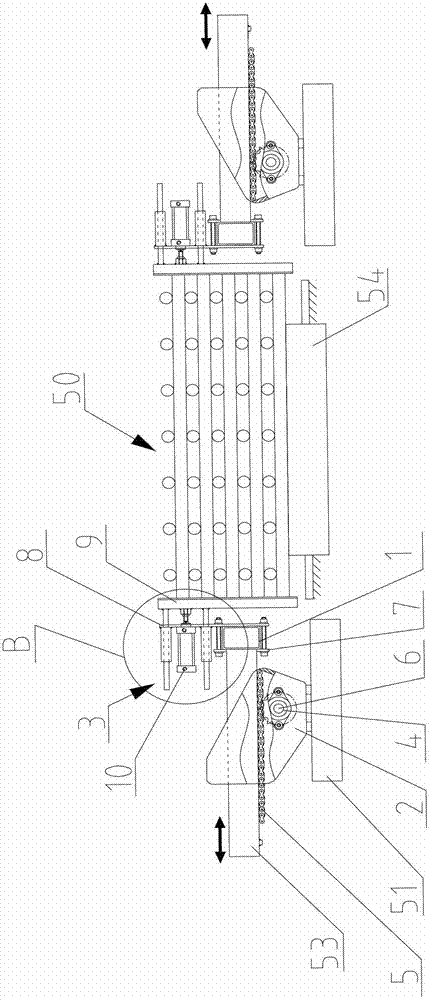

[0020] As shown in the figure, the present invention provides a stepless adjustment and alignment device for welded mesh. The stepless adjustment and alignment device has a pair of structures symmetrically arranged on both sides of a plurality of welded meshes 50 stacked in the same position. The stepless adjustment The alignment device includes an alignment connecting arm 9, one side of the alignment connecting arm 9 contacts the side of the welded mesh 50, and the other side of the alignment connecting arm 9 is fixedly connected with an end of a side bracket 53 arranged vertically to the side. The other end of side support 53 passes through the through hole of fixed support 2, and the bottom of des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com