Metal-matrix composite chemical heat-storage material and method for preparing same

A metal-based composite and chemical heat storage technology, which is applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem of low thermal conductivity of chemical heat storage materials, achieve a wide range of applications, improve thermal conductivity, and thermal conductivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

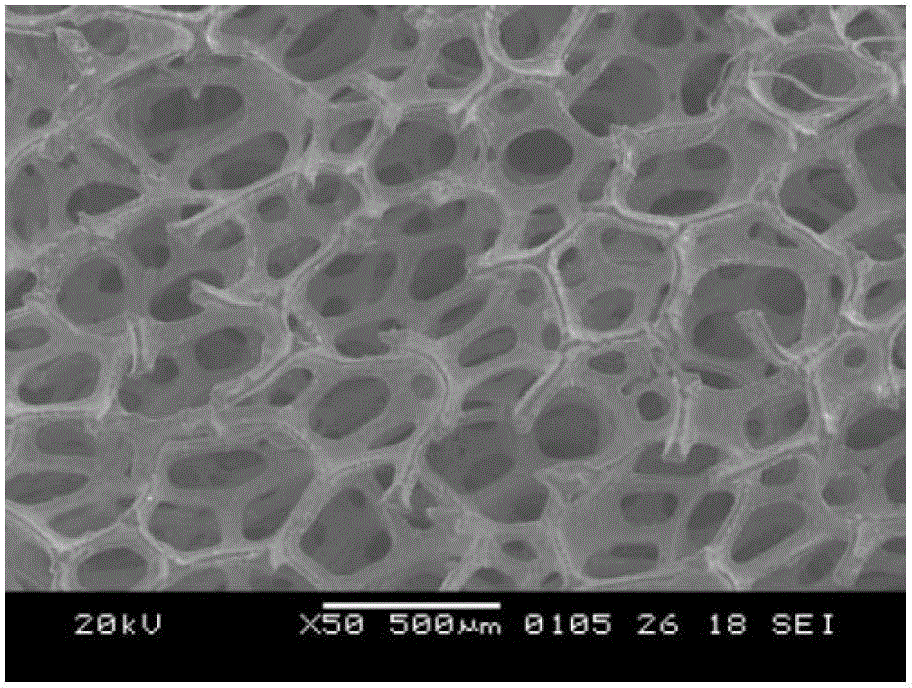

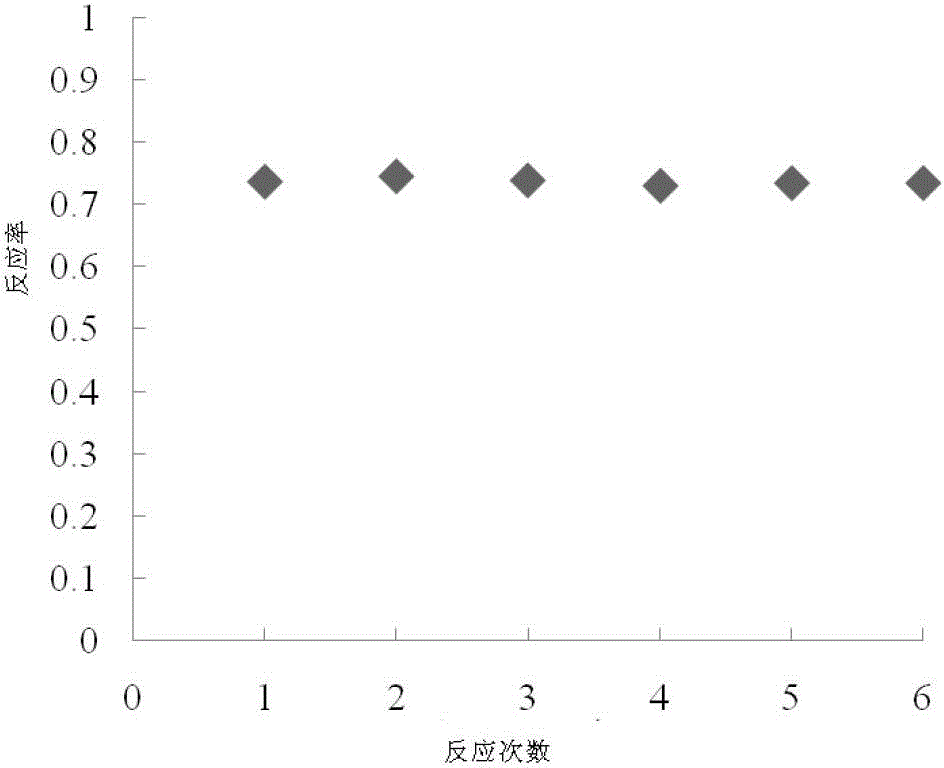

[0028] The chemical heat storage material adopts Ca(OH) 2 , the metal matrix adopts Ni foam, the specific preparation method is as follows: first 300g Ca(OH) 2 Add 400g of distilled water and stir until uniform to make a suspension; 300g of foam Ni with three different pore sizes (450μm, 700μm, and 900μm) were used to immerse the above suspension respectively, and pressurized and impregnated for 10 minutes under the condition of 0.9MPa. Repeat pressure impregnation for 5 times, then take out the base material and dry it in a constant temperature oven at 120°C for 24 hours to make a nickel-based composite chemical heat storage material. It is measured that the loading rates of composite chemical heat storage materials with pore diameters of 450 μm, 700 μm and 900 μm are 52%, 49.5% and 49%, respectively. figure 2 It is a schematic diagram of the reaction rate of the nickel-based composite chemical heat storage material changing with the number of reactions. It can be seen from...

Embodiment 2

[0030] The chemical heat storage material adopts Ca(OH) 2 , the metal substrate is made of foamed Cu, the specific preparation method is as follows: first 300g Ca(OH) 2 Add 700g of distilled water and stir until uniform to form a suspension; use 300g of foam Cu with a pore size of 600μm to immerse in the above suspension, pressurize and impregnate for 15 minutes under the condition of 0.7MPa, repeat pressurized impregnation for 7 times, then take out the matrix material and place After drying in a constant temperature oven at 120°C for 24 hours, a copper-based composite chemical heat storage material is produced.

Embodiment 3

[0032] The chemical heat storage material uses Mg(OH) 2 , the metal substrate is made of foamed Cu, the specific preparation method is as follows: first, 300g Mg(OH) 2 Add 1200g of distilled water and stir until uniform to form a suspension; 200g of Cu foam with a pore size of 500μm is used to immerse the above suspension, pressurized and impregnated for 20 minutes under the condition of 0.5MPa, and repeatedly pressurized and impregnated 8 times, then take out the matrix material and place After drying in a constant temperature oven at 120°C for 24 hours, a copper-based composite chemical heat storage material is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com