Single-phase white light phosphor for near-ultraviolet light excitation and preparation method thereof

A near-ultraviolet light and phosphor technology, applied in the field of luminescence, can solve the problems affecting lumen efficiency and color reproduction performance, and achieve the effect of overcoming color imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the single-phase white light phosphor of the present invention includes the following steps:

[0027] a. To contain Ce oxide, carbonate, nitrate or halide, Eu oxide, carbonate, nitrate or halide, Sc oxide, carbonate, nitrate or halide, Mn Oxides, carbonates, nitrates or halides, Si oxides and Ba oxides, carbonates, nitrates or halides as raw materials, according to the chemical formula of the single-phase white phosphor Metering ratio, calculate and weigh the above raw materials, and grind and mix;

[0028] b. Put the above mixture into a corundum crucible, put it into a high temperature furnace, and place it in CO or H 2 It is calcined under reducing conditions, the calcining temperature is 1050 DEG C.-1350 DEG C, the firing time is 2-4 hours, and the single-phase white phosphor can be obtained by grinding after natural cooling.

Embodiment 1

[0032] Preparation of Ba 9 Sc 1.95 Ce 0.05 (SiO 4 ) 6 (Ie Ba 9-x-y Eu x Mn y Sc 2-z Ce z (SiO 4 ) 6 In, when x=0, y=0, z=0.05) phosphor.

[0033] Weigh BaCO according to the stoichiometric ratio 3 0.8880 g, Sc 2 O 3 0.0673 g, CeO 2 0.0043 g, SiO 2 0.1802g, put it in an agate mortar, fully grind and mix, put the mixture in a corundum crucible, cover it, place it in a high-temperature furnace, and place it in CO or H 2 In a reducing atmosphere, heat to 1050-1350°C, keep constant temperature for 2-4 hours, cool naturally and grind to obtain the composition Ba 9 Sc 1.95 Ce 0.05 (SiO 4 ) 6 Of phosphors.

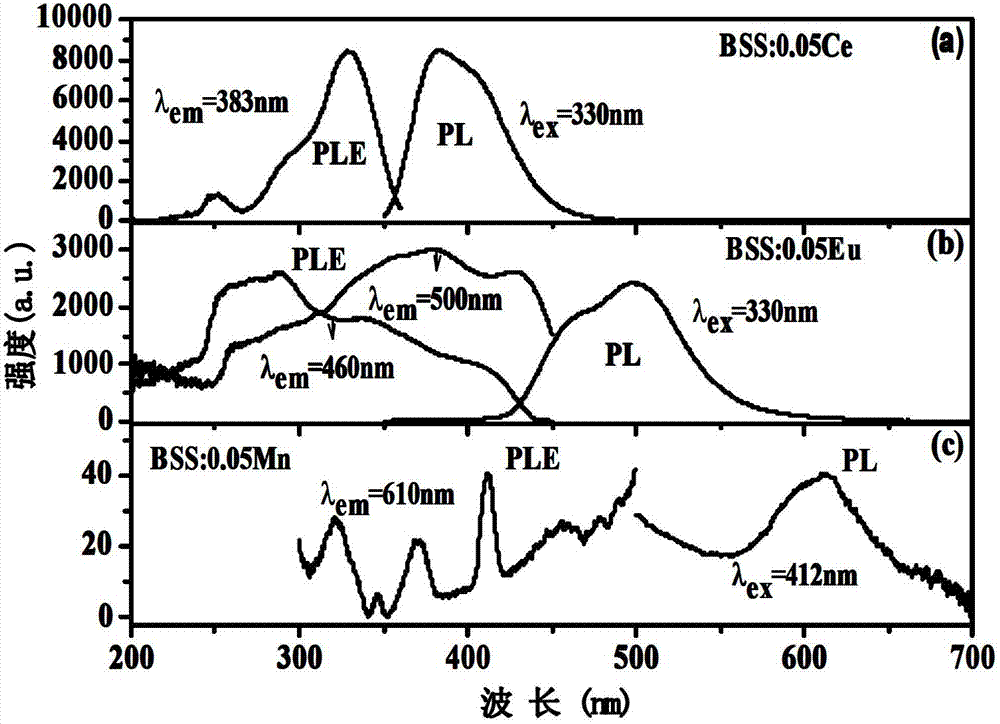

[0034] figure 1 (A) The excitation spectrum of the phosphor (λ em =383nm) and emission spectrum (λ ex =330nm), it can be seen from the figure that Ce 3+ Individually activated Ba 9 Sc 2 (SiO 4 ) 6 Under the excitation of 280-350nm ultraviolet light, the phosphor emits blue-violet light with a wavelength range of 360-440nm and a peak value of 383nm, and the emission is very strong.

Embodiment 2

[0036] Preparation of Ba 8.95 Eu 0.05 Sc 2 (SiO 4 ) 6 (Ie Ba 9-x-y Eu x Mn y Sc 2-z Ce z (SiO 4 ) 6 In, when x=0.05, y=0.00, z=0.00) phosphor.

[0037] Weigh BaCO according to the stoichiometric ratio 3 0.8831 g, Sc 2 O 3 0.0690 g, Eu 2 O 3 0.0044 g, SiO 2 0.1802g, put it in an agate mortar, fully grind and mix, put the mixture in a corundum crucible, cover it, place it in a high-temperature furnace, and place it in CO or H 2 Under reducing atmosphere, heat to 1050-1350°C, keep constant temperature for 2-4 hours, cool naturally and grind, then the composition is Ba 8.95 Eu 0.05 Sc 2 (SiO 4 ) 6 Of phosphors.

[0038] figure 1 (B) The excitation spectrum of the phosphor (λ em =460nm, λ em =500nm) and emission spectrum (λ ex =330nm), as can be seen from the figure, Eu 2+ Individually activated Ba 9 Sc 2 (SiO 4 ) 6 Under the excitation of 300-450nm ultraviolet light, the phosphor emits blue-green light with a wavelength range of 430-550nm and peaks of 460nm and 500nm, and the emissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color temperature | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com