Method for spinning segment color yarn by front area segmentation and drawing mechanism

A technology of spinning frame and front drafting area, applied in spinning frame, drafting equipment, textile and papermaking, etc., can solve the problem of large drafting ratio in front area, inability to precisely control segment color distribution, inability to quickly and short distance Exchange and other issues to achieve the effect of expanding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

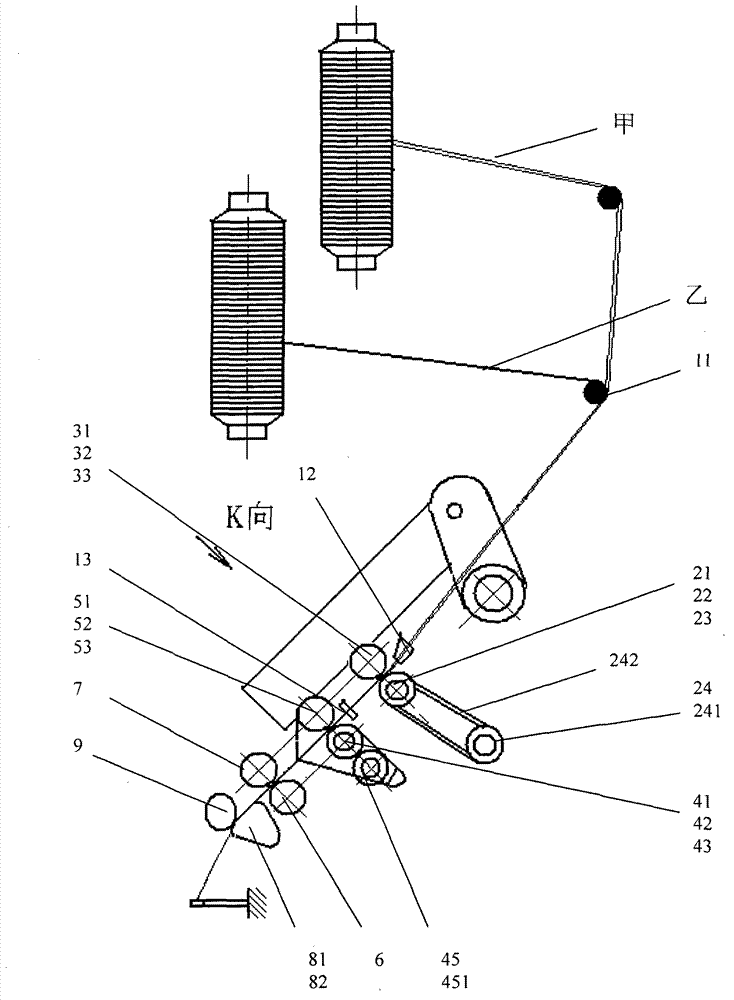

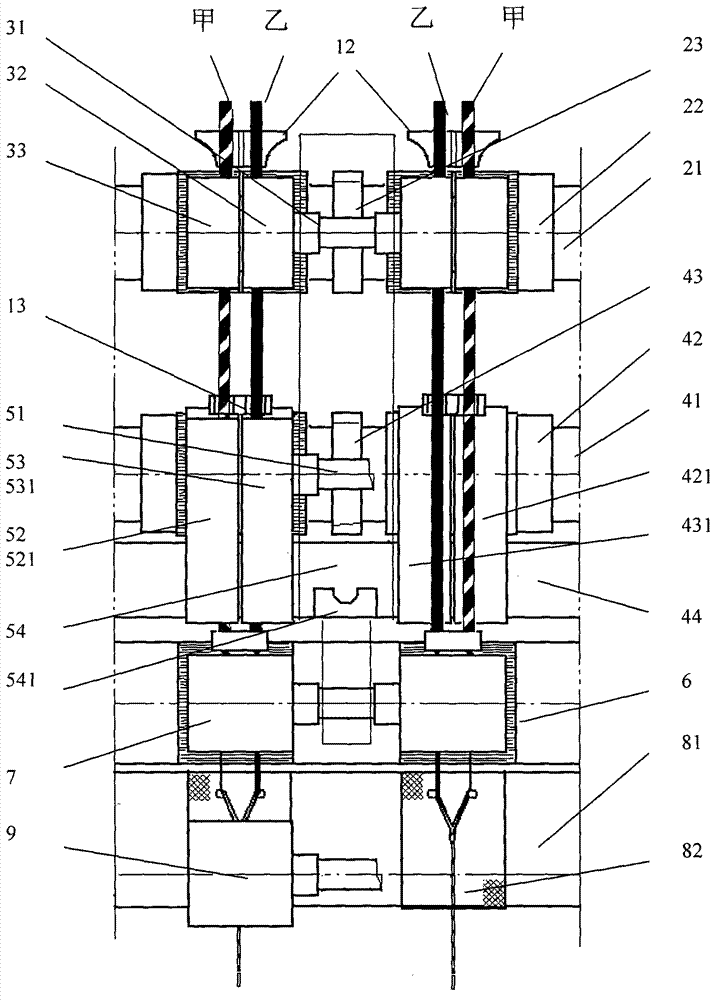

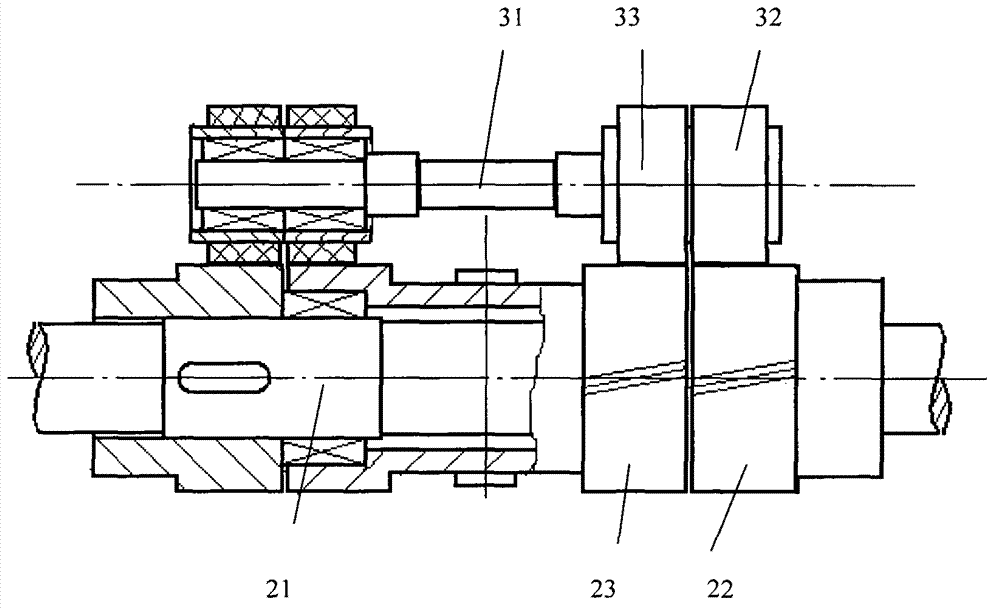

[0025] Such as figure 1 and figure 2 As shown, the present invention is a method for segmented color spinning in the front section of a spinning frame. The fiber strips of groups A and B are respectively fed from the rear roller through the yarn guide bar (11) and the double-hole bell mouth (12). The back fixed roller (22) and the back looper roller (23) on the roller shaft (21) are clamped respectively, and through the double-channel yarn guide (13), the corresponding middle fixed roller ( 42) and the middle looper roller (43), which are elastically gripped by the middle roller lower apron (421, 431) and the middle roller upper apron (521, 531) and transported forward to the front roller (6), in the front drafting area , the speeds of the middle rollers in the two groups are different, the drafting multiples of the front area of the two groups of fiber strands are different, and vary with the speed of the middle rollers, the second group of fiber strands after being draft...

Embodiment 2

[0032] Such as Figure 6 As shown, a segmented color spinning yarn drafting mechanism in the front area of the spinning frame can be combined with the filament feeding device. The filament tension device (101) is installed on the cradle, and the filament positioning guide wheel (102) is installed on the Above the front roller, the filament (c) passes through the filament tension device (101) and the filament positioning guide wheel (102), and is positioned and fed behind the front roller, that is, it has the function of composite processing of filament, and can produce long and short fiber composite segment color Yarn or multi-component functional yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com