Oiling-free automobile transmission shaft

A drive shaft, oil-free technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve problems such as drive shaft failure, grease overflow, grease expansion, etc., to increase service life and prevent premature Wear and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

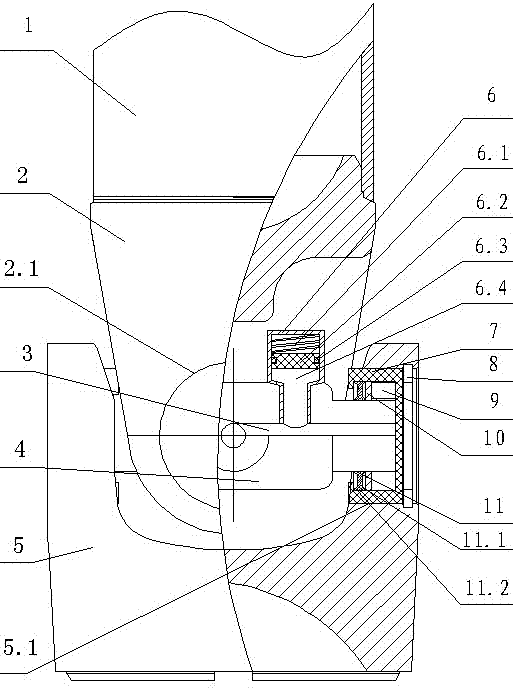

[0013] see figure 1 , the present invention includes shaft tube 1, welding fork 2, welding fork ear hole 2.1, through hole 3, cross shaft 4, flange fork 5, flange fork ear hole 5.1, oil storage device 6, return spring 6.1, piston 6.2, seal Ring 6.3 oil storage chamber 6.4, shaft sleeve 7, snap ring 8, needle roller 9, wear-reducing ring 10, double-lip type circlip 11. Cross shaft 4, flange fork 5, oil seal screw 6, bushing 7, snap ring 8, needle roller 9, wear-reducing ring 10, double-lip circlip 11, circlip inner lip 11.1, circlip outer Lip 11.2 constitutes the universal joint.

[0014] The shaft tube 1 is connected to the welding fork 2 by welding, and the two sides of the welding fork 2 are provided with welding fork ear holes 21 . Both sides of the flange fork 5 are also provided with flange fork ear holes 51, and the axle sleeves 7 of the universal joint are housed in the welding fork ear holes 21 and the flange fork ear holes 51, and the axle sleeves 7 are sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com