Method for evaluating rubber mixing process

An evaluation method and technology of rubber mixing, applied in suspension and porous material analysis, measurement device, particle and sedimentation analysis, etc., can solve the problem that the detection results reflect the local dispersion situation, and cannot evaluate the overall mixing state of carbon black, preparation and The problem of high operating costs is to achieve the effect of simple and reliable design principle, clear evaluation index, and simple and easy-to-control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

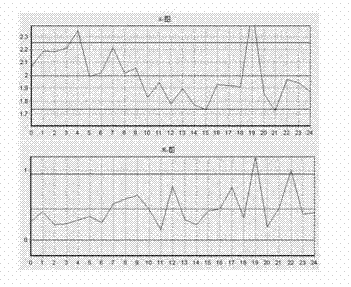

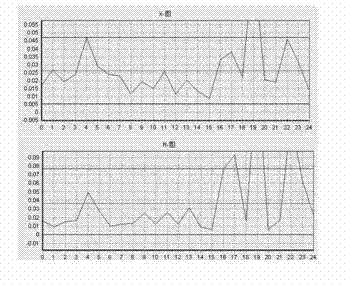

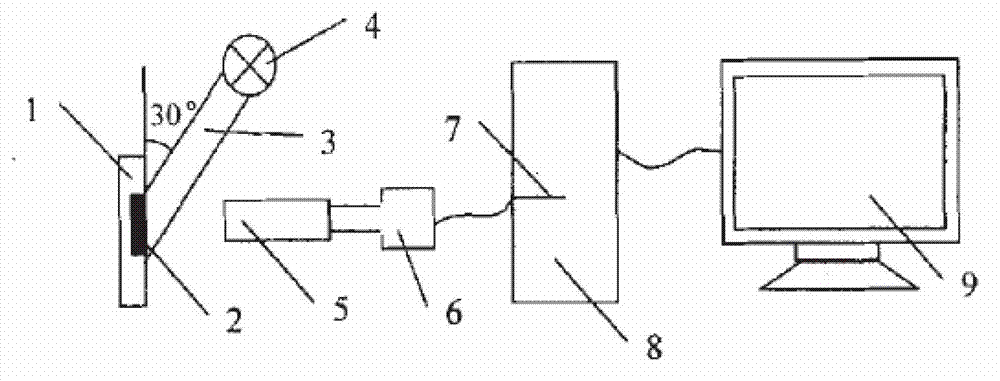

[0039]In this example, first use a sharp blade to cut the rubber material, and obtain 25 samples whose length, width, and thickness are 500mm, 240mm, and 5mm respectively; try to ensure that the sliced surface is smooth without scratches. The unbalanced color of the resulting image increases the difficulty of image processing; if there is a scratch, its border is also bright, which is easy to be confused with the color of carbon black; then the parallel light at 30 degrees to the cut surface of the rubber is irradiated to the cut surface, and the optical Digital imaging is carried out after zooming in, the overall magnification is 100 times, the grayscale image of the rubber is obtained, and binarization is performed, the segmentation threshold is set to 100, and a black and white image is formed; then, the white area in the entire black and white image is traversed to calculate The average radius of carbon black aggregates and the concentration in the rubber compound; Repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com