Solar cell assembly

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of increasing the demand for welding strips and increasing labor intensity, and achieve the effect of reducing welding labor intensity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

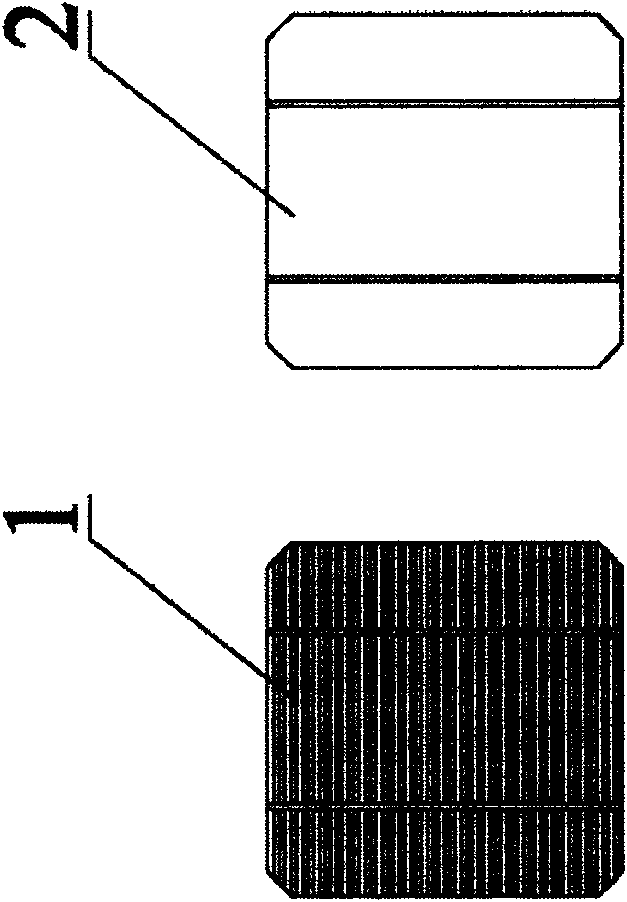

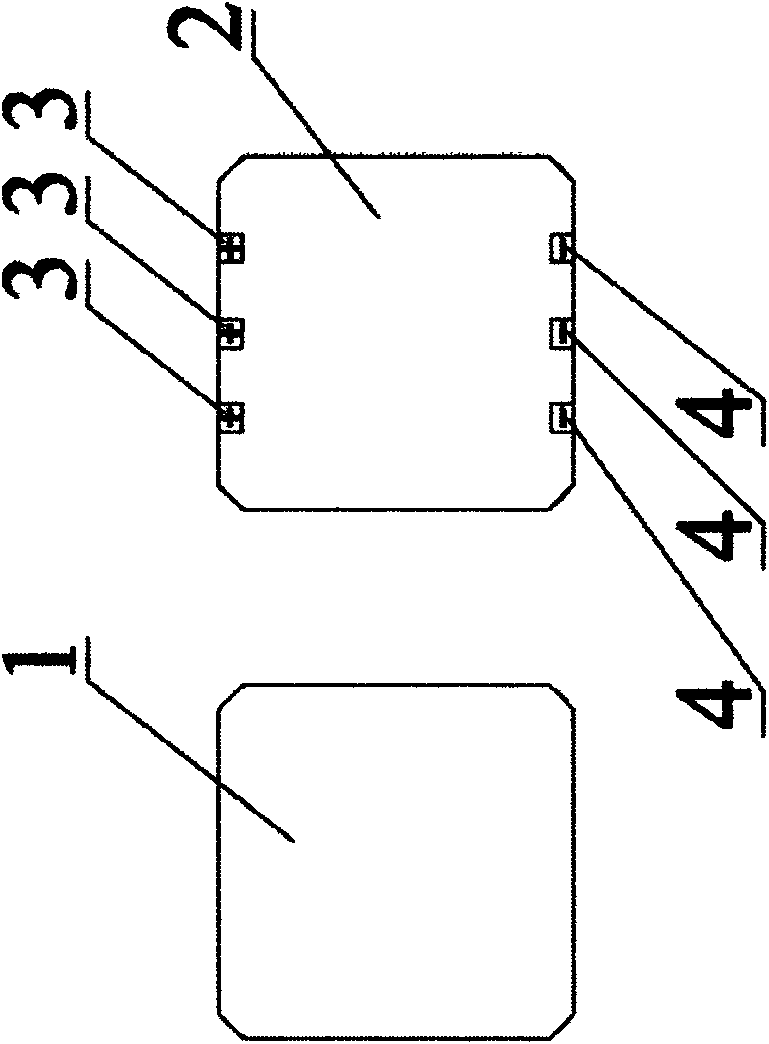

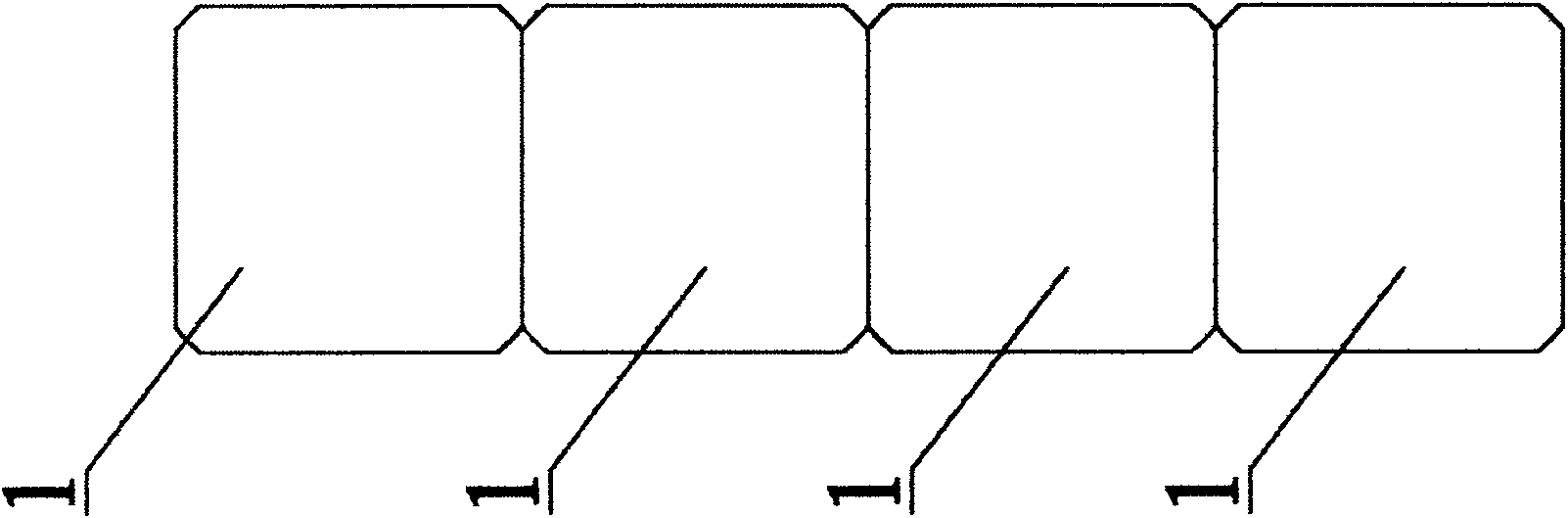

[0013] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a solar cell assembly of the present invention is formed by connecting a plurality of battery sheets in series. The front side 1 of the battery sheet has no main and auxiliary grid lines, and the back side 2 of the battery sheet is processed with positive electrode solder joints 3 , corresponding to The corresponding other side is processed with a negative electrode solder joint 4 .

[0014] The positive electrode solder joints 3 and the negative electrode solder joints 4 on the back of adjacent battery sheets are welded together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com