Motor bearing lubricating structure and motor for wet operating pump

A technology for motor bearings and lubricating structures, applied in the direction of magnetic circuit shape/style/structure, casing/cover/support, electromechanical devices, etc., can solve the problems of high manufacturing cost and complex structure, and achieve low cost and excellent preparation process Simple, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

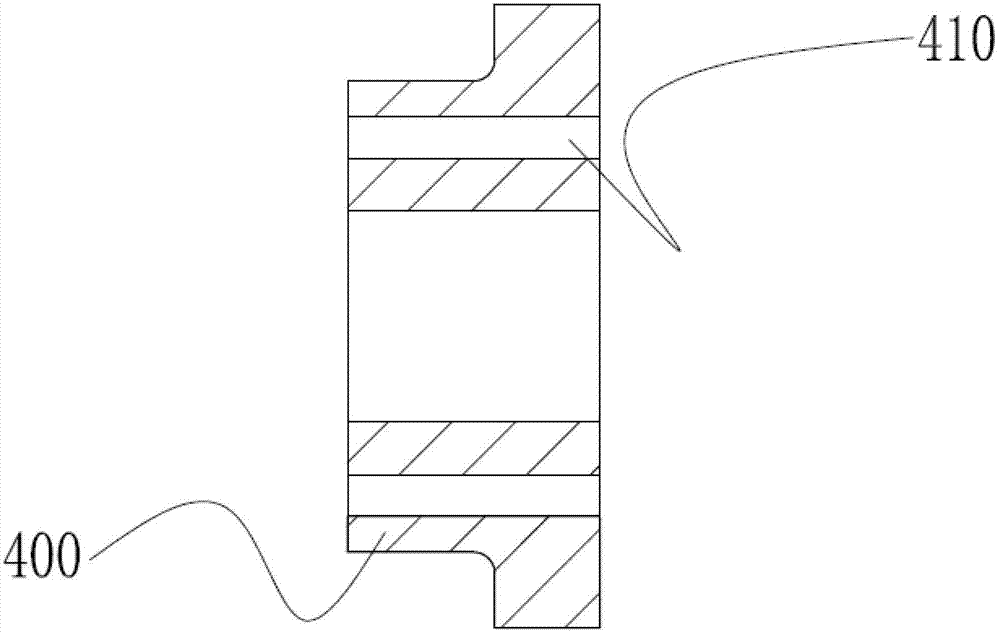

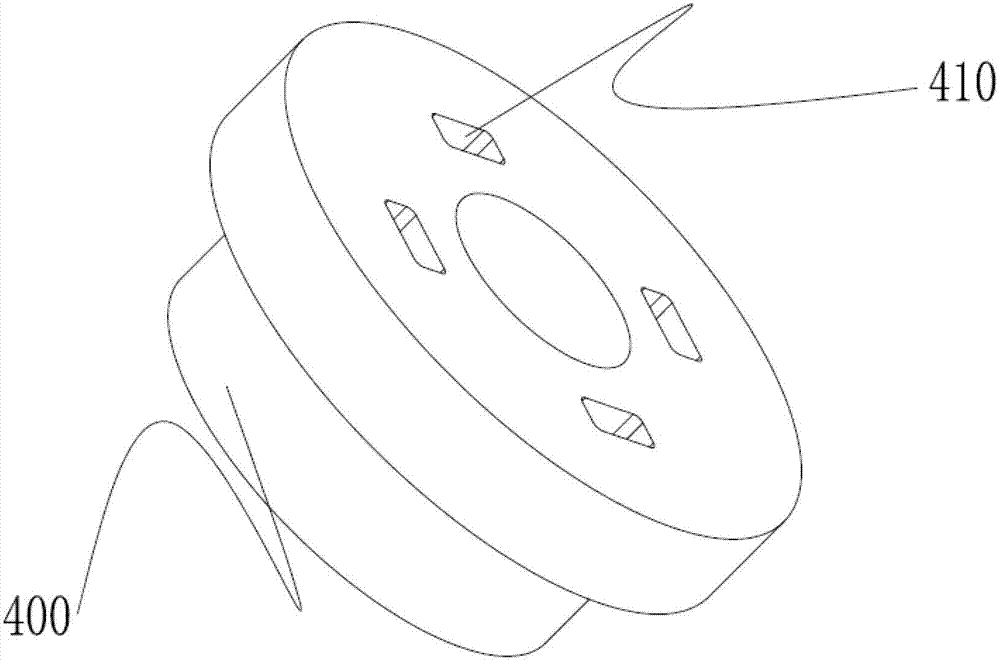

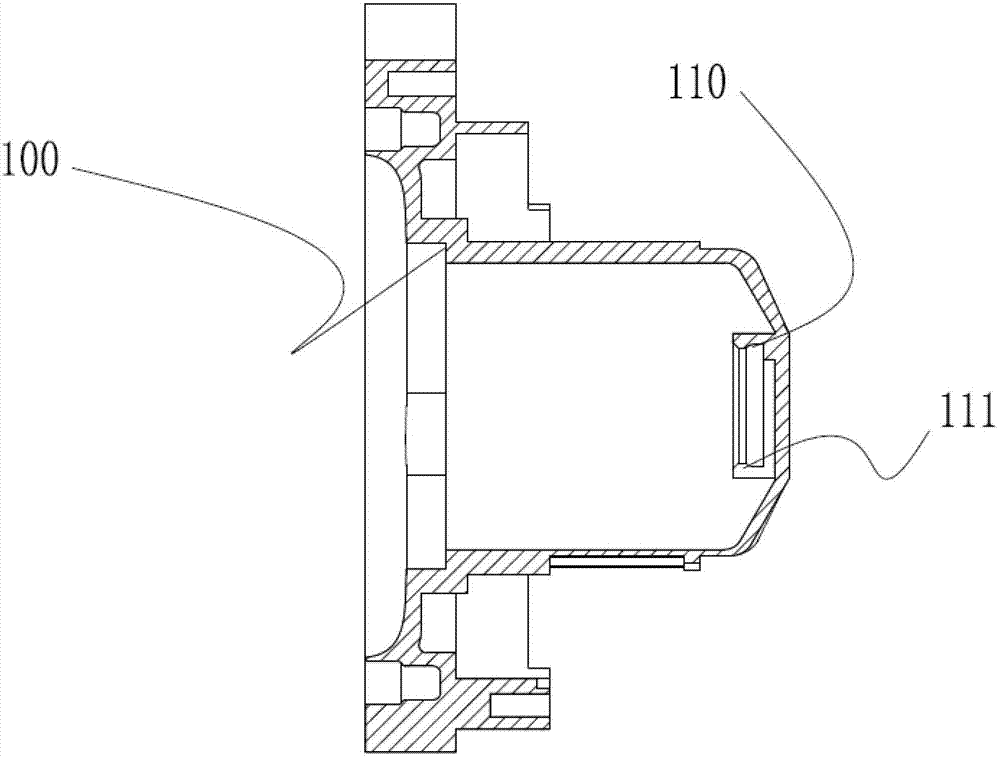

[0073] Embodiment 1. A motor bearing lubrication structure for a wet-running pump. The motor for a wet-running pump includes a sleeve 100, a stator assembly 200, and a rotor assembly 300. The sleeve 100 is located between the stator assembly 200 and the rotor assembly 300. The rotor assembly 300 is located in the casing 100, and the casing 100 seals the space of the rotor assembly 300 relative to the space of the stator assembly 200, and the bearing 400 is arranged between the rotating shaft 310 of the rotor assembly 300 and the bottom of the casing 100, wherein: on the body of the bearing 400 One or more fluid channels are provided.

Embodiment 2

[0074] Embodiment 2. A motor bearing lubrication structure for a wet-running pump, wherein: the fluid channel is a through hole 410, and the rest are the same as in Embodiment 1.

Embodiment 3

[0075] Embodiment 3. A motor bearing lubrication structure for a wet-running pump, wherein: the fluid channel is a groove, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com