Direct grid-tied variable-speed constant-frequency generator

A main generator, generator rotor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of high cost, high failure rate, complex production and assembly process, etc., to achieve improved power quality, reduced failure rate, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

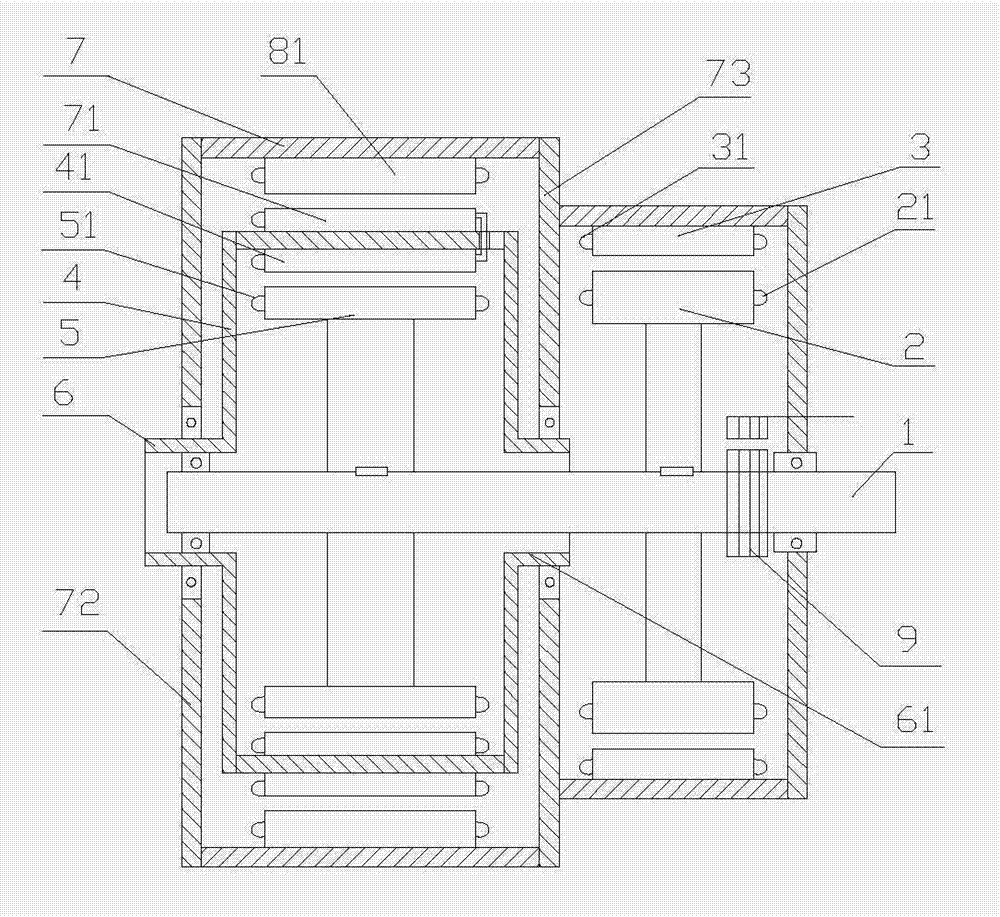

[0016] Such as figure 1 As shown, the direct grid-connected variable speed constant frequency generator of the present invention includes a main shaft 1, a generator rotor 2 fixedly mounted on the main shaft 1, and a generator stator 3 arranged around the generator rotor 2 to generate electricity The generator rotor 2 is equipped with a generator DC excitation coil 21, the generator stator 3 is equipped with a generator armature coil 31, the generator stator 3 is installed on the main shaft 1 through a bearing, and the generator rotor 2 is fixedly installed on the main shaft 1 to generate electricity. The stator 3 and the rotor 2 of the generator form an air gap fit.

[0017] A generator exciter is also installed on the main shaft 1. The generator exciter includes an exciter armature 4 mounted on the main shaft 1 through a bearing, an exciter rotor 5 fixedly mounted on the main shaft 1, and an exciter rotor 5 The DC excitation coil 51 of the exciter rotor is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com