Intermittent fillet control method for single-phase brushless direct-current motors

A brushed DC motor and control method technology, applied in torque ripple control and other directions, can solve problems such as increasing motor loss and aggravating motor vibration, reducing vibration and noise, and improving operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

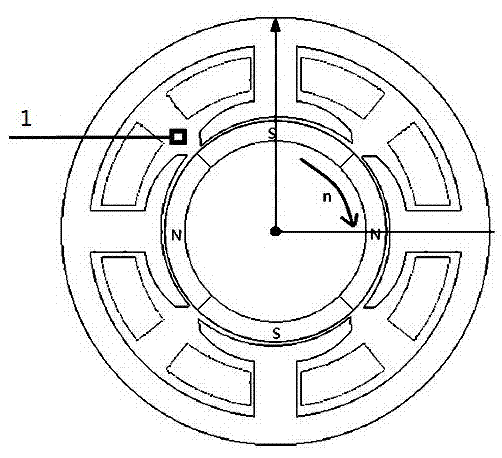

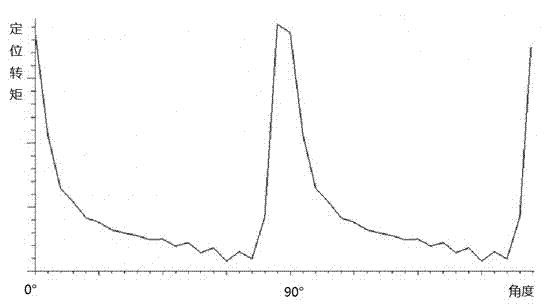

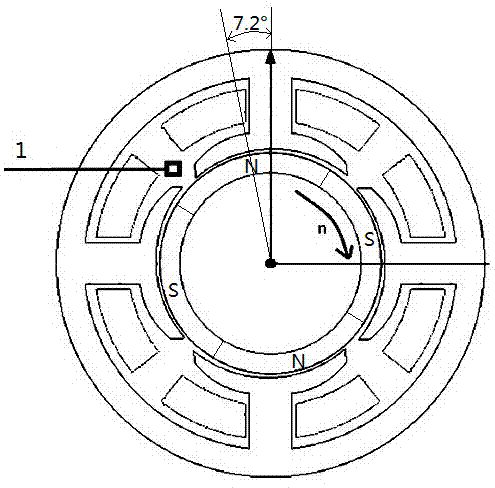

[0013] The principle of the present invention is to adopt the discontinuous angle control mode after analyzing the detent torque characteristic of the single-phase brushless DC motor. In the control process, in order to avoid the above-mentioned peak current generation, it is necessary to select a suitable position to temporarily cancel the power supply to the armature winding, and only rely on the positioning torque of the motor itself to drag the motor, that is, to realize the intermittent operation of the current.

[0014] Since an important criterion for judging the performance of a motor is the efficiency of the motor, and the existing control strategies for single-phase brushless DC motors do not avoid the positioning torque of the motor, so it is difficult to further improve the efficiency. By analyzing the inherent characteristics of the detent torque of the single-phase brushless DC motor itself, the new discontinuous angle control method mentioned in the present inven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap