Chain link, conveyor element, and device for compressing tobacco, ribs, or the like

A technology of conveying elements and strips, which is applied in the field of chain links, can solve the problems of conveyor chain wear, wrong orientation, and guide conveyor chains, and achieve the effects of small tolerance requirements, cost reduction, and reliable guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

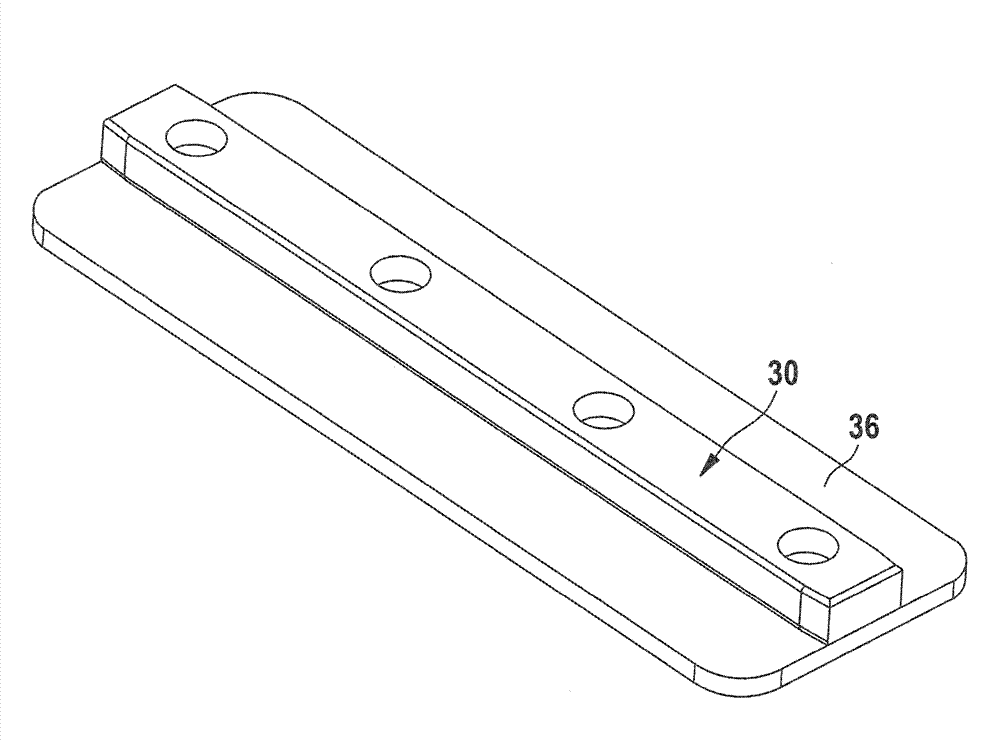

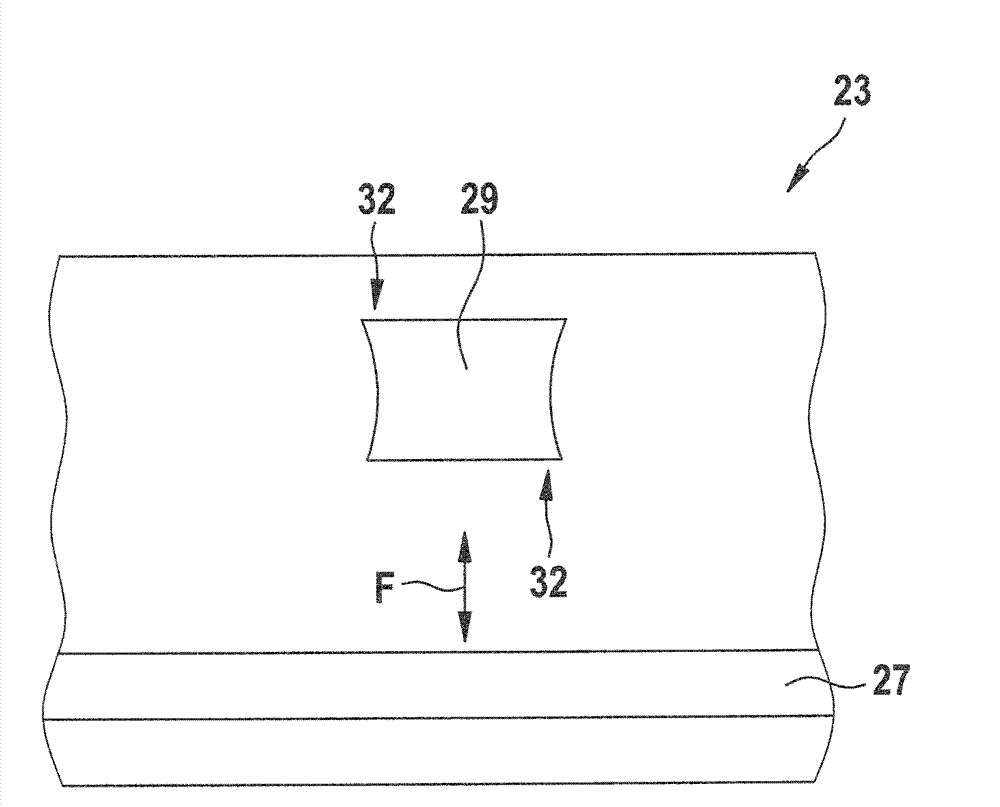

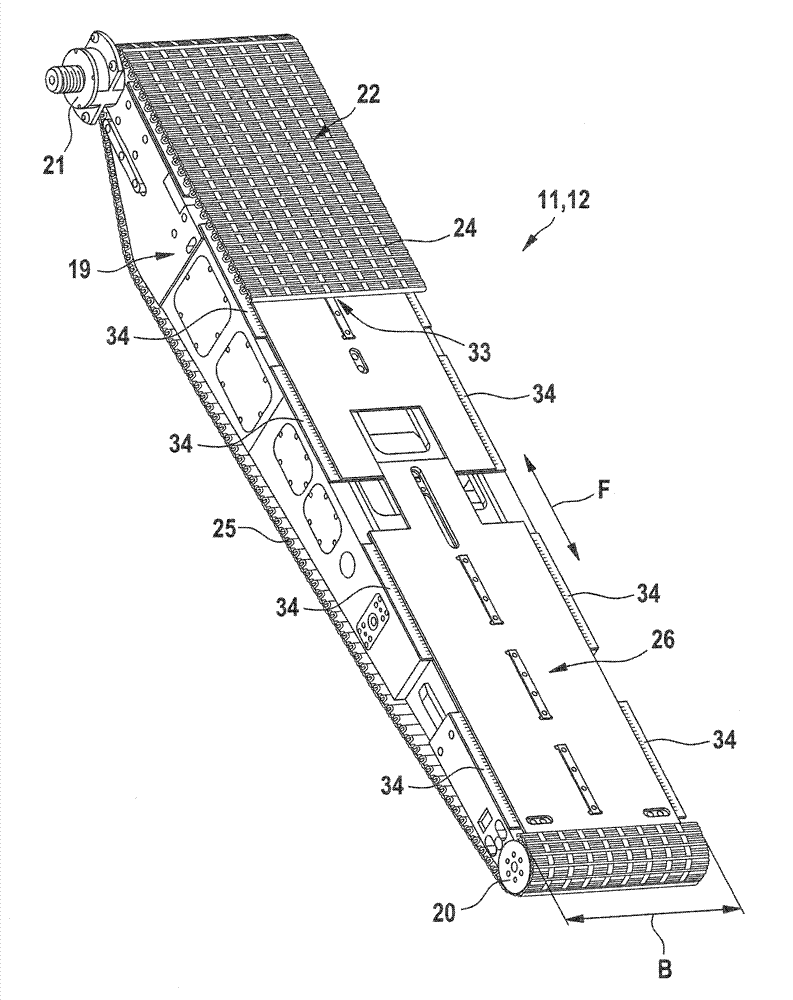

[0025] The device and parts of the device shown in the figures are used for compressing tobacco, rods or the like. The parts of the device, in particular the chain links and the conveying elements, are designed and arranged to form a conveying chain for such a device or to convey tobacco, rods or the like in such a device.

[0026] figure 1 The device 10 shown in for compressing tobacco, rods or the like comprises two conveying elements 11 , 12 . The two delivery elements 11 , 12 are arranged one above the other and each form a compression element. The two conveying elements 11 , 12 are arranged tapering toward the nozzle 13 , so that the tobacco or the like conveyed in the conveying direction F is compressed into a tobacco cake and cut into small pieces in the region of the cutting surface S. The conveying elements 11 , 12 can optionally be designed to be fixed relative to each other or to be movable towards or away from each other. However, a distance change and / or a chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com