Lithium disilicate glass-ceramic, its production method and its use

A glass ceramic, lithium disilicate technology, used in pharmaceutical formulations, photometry using electrical radiation detectors, dental preparations, etc., to achieve the effect of improving chemical stability and high strength values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

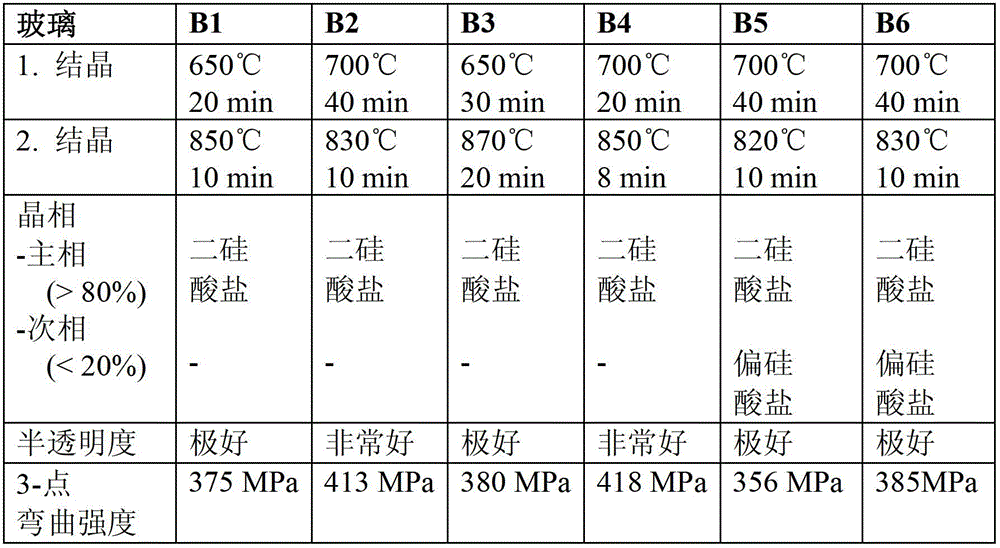

[0029] In Examples 1-6, glass compositions with high zirconia content are shown, which are transformed by a two-step temperature treatment: first into an easily machined lithium metasilicate glass-ceramic; subsequently Transforms into a highly translucent, very strong and chemically stable lithium disilicate glass-ceramic.

[0030] In Table 1 the compositions and their components are shown.

[0031] Table 1

[0032] B1

B2

B3

B4

B5

B6

SiO 2

66.9

65.8

65.5

63.7

63.5

63.5

Li 2 o

13.9

13.7

13.6

13.2

14.4

12.9

ZrO 2

10.0

10.0

12.0

11.7

12.7

13.5

Al 2 o 3

3.2

3.1

3.1

3.0

3.3

3.5

P 2 o 5

3.0

3.0

3.0

2.9

3.1

3.4

K 2 o

2.9

2.9

2.9

2.8

3.0

3.2

CeO 2

-

1.0

-

2.0

-

-

Er 2 o 3

-

0.2

-

0.3

-

-

Tb 2 o 3

-

0.3

-

0.3

-

- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com