Lubricating oil composition

A lubricating oil composition and composition technology, applied in lubricating compositions, gear lubrication/cooling, petroleum industry, etc., can solve problems such as poor oil film retention, achieve excellent low-temperature viscosity characteristics, maintain fatigue life, and save fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

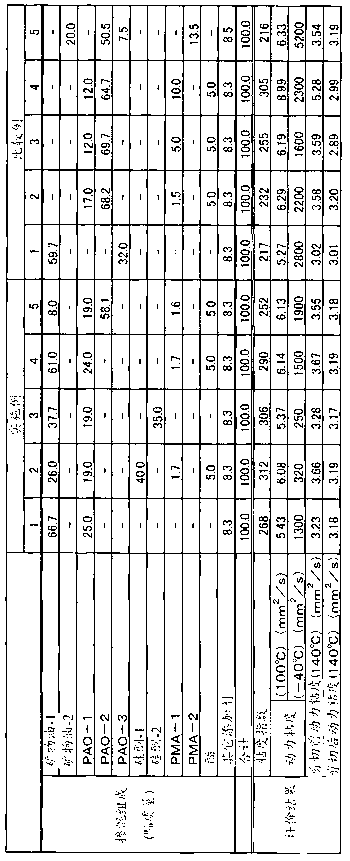

[0062] [Examples 1-5, Comparative Examples 1-5]

[0063] Lubricating oil compositions were prepared according to the compositions shown in Table 1, and the dynamic viscosities and post-shear viscosities of the prepared compositions at 100°C and -40°C were measured according to the methods shown below.

[0064] It should be noted that the components recorded in Table 1 are as follows:

[0065] Mineral oil-1: The sulfur content is 0.03% by mass or less, and the dynamic viscosity at 100°C is 1.0 mm 2 / s, the dynamic viscosity at 40°C is 2.6mm 2 / s mineral oil

[0066] Mineral oil-2: The sulfur content is 0.03% by mass or less, and the dynamic viscosity at 100°C is 6.5mm 2 / s, the dynamic viscosity at 40°C is 37mm 2 / s mineral oil

[0067] PAO-1: Dynamic viscosity at 100°C is 300mm 2 / s PAO

[0068] PAO-2: Dynamic viscosity at 100°C is 1.8mm 2 / s PAO

[0069] PAO-3: Dynamic viscosity at 100°C is 100mm 2 / s PAO

[0070] Esters: dynamic viscosity at 100°C is 3.4mm 2 / s b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com