Cleaning tool for mica groove of direct current motor

A DC motor and mica technology, applied in cleaning methods and appliances, cleaning methods using tools, chemical instruments and methods, etc., can solve the potential safety hazards of DC motors in normal operation, increase the maintenance cost of DC motors, and poor cleaning effects, etc. problems, to achieve the effect of saving maintenance costs, ensuring safe and normal operation, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

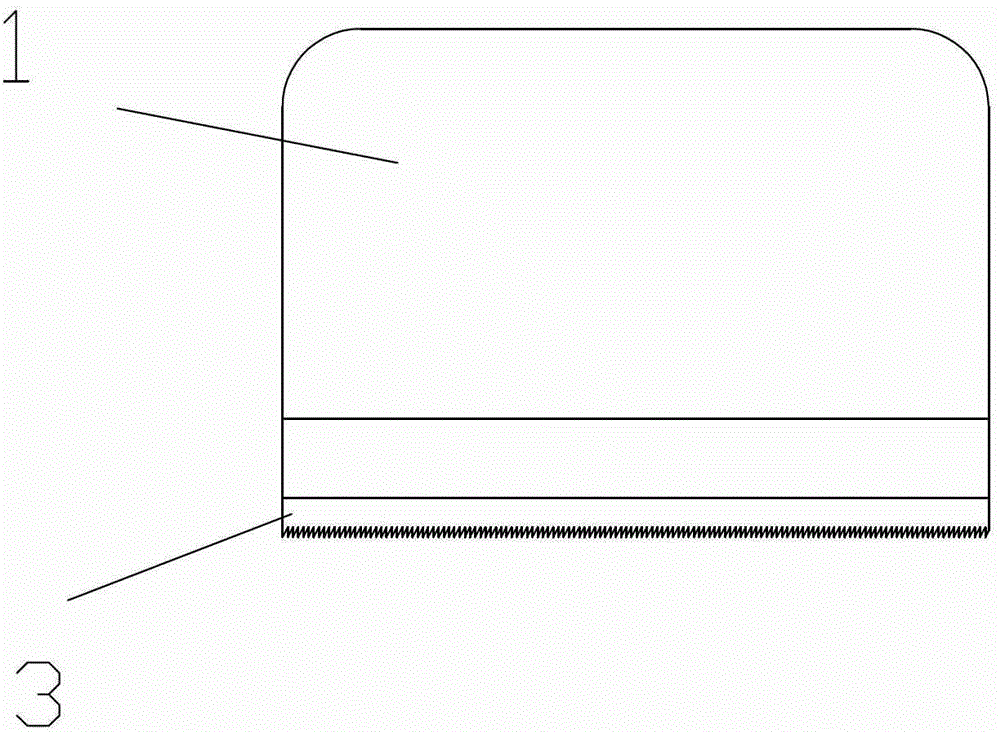

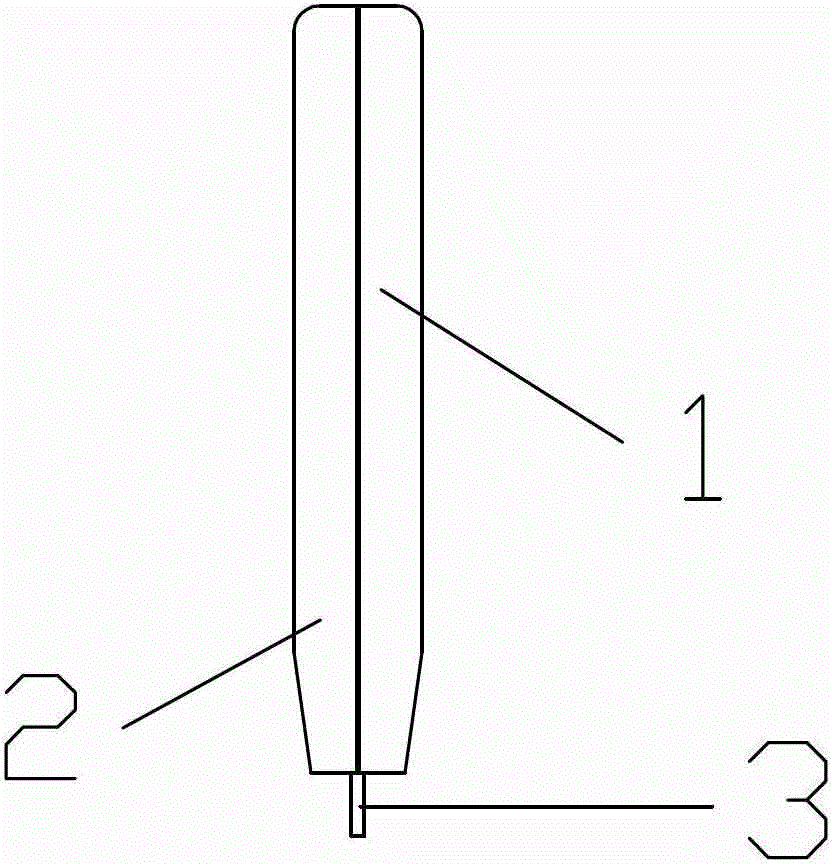

[0014] A DC motor mica tank cleaning tool provided in this embodiment is used to clean carbon powder and conductive dust in the DC motor mica tank. The structure is shown in the figure, including a clamping part 1 and a clamping part 2. In this embodiment The clamping part preferably adopts a rubber-plastic plate. The saw blade 3 is clamped between the lower edges of the clamping parts 1 and 2, and the two are fixed as one by AB glue. At the same time, the tooth length of the saw blade is preferably 1.5mm-2mm. In addition, the upper edges of the clamping parts 1 and 2 adopt a circular arc structure, which is convenient for grasping.

[0015] When the above device is in use, use the index finger and middle finger to clamp the two sides of the cleaning tool, press the index finger and the palm respectively to press the arcs on both sides of the rubber and plastic plate, first pull the groove along the mica groove up 45 degrees, and then along the mica groove 45 degrees down Pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com