Cross-piece steel coil horizontal transport carrier

A cross-blocking, transport rack technology, applied in the field of cargo transport racks, can solve the problems of hazards, bulkiness, and high production costs, and achieve the effects of easy recovery and transportation, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

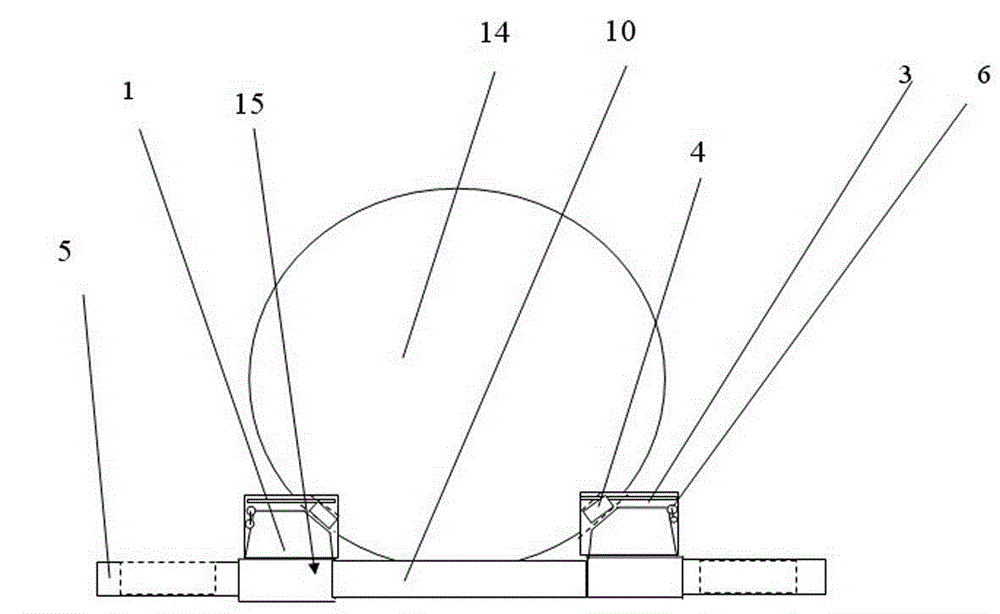

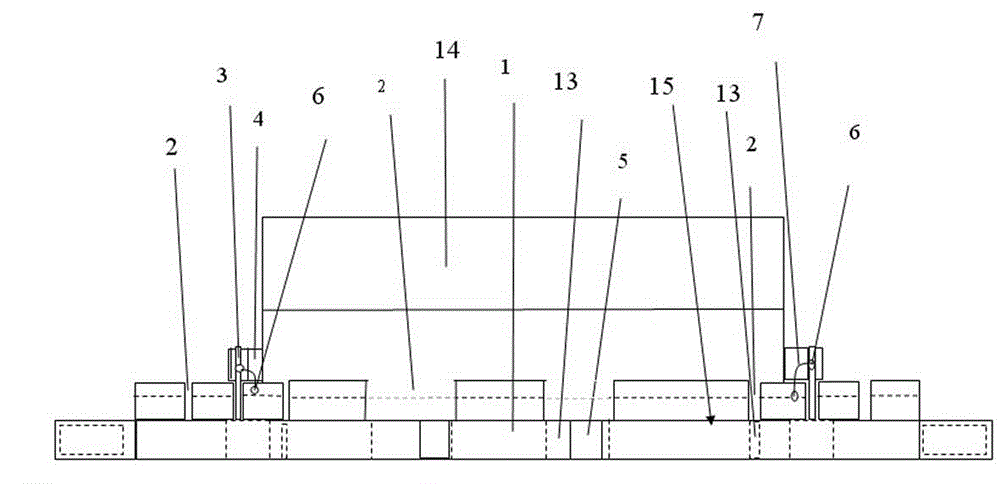

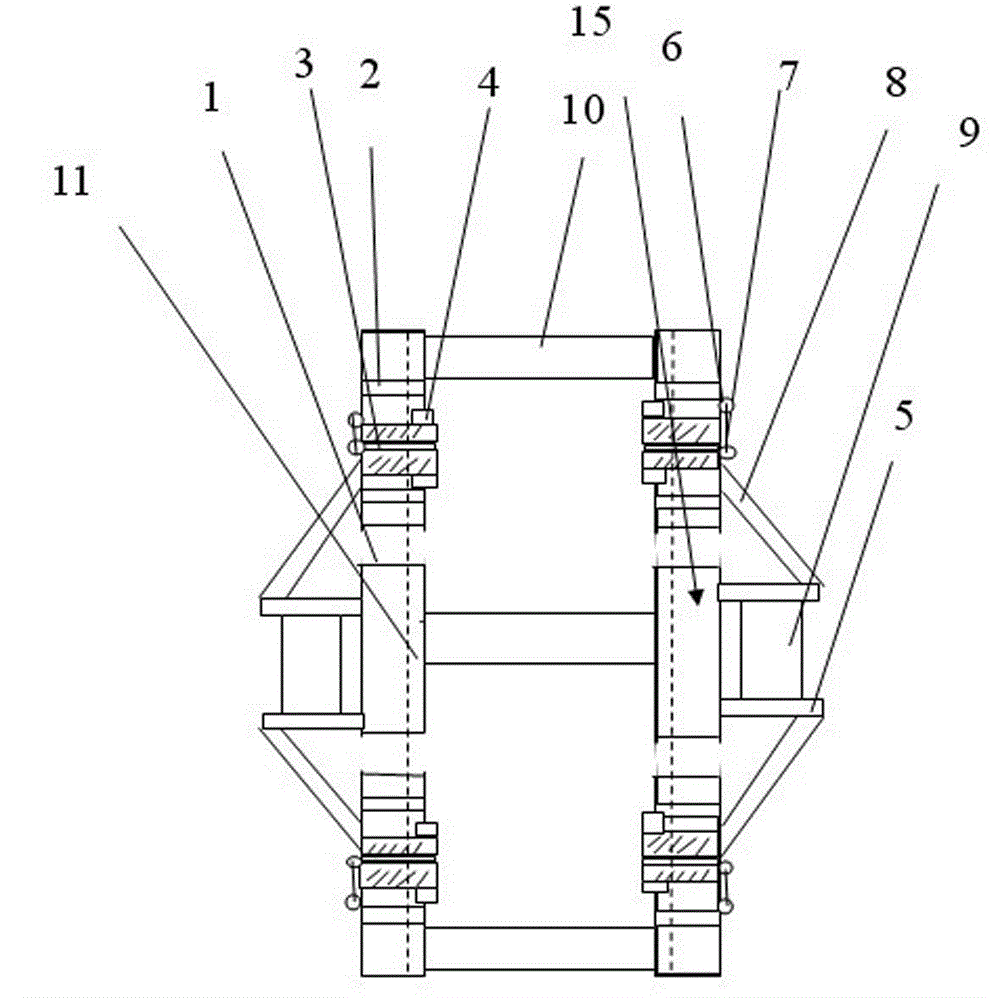

[0022] See figure 1 , figure 2 , image 3 , the cross-block type steel coil horizontal loading transport frame of the present invention includes an underframe 15, and the underframe 15 is composed of two side support frames 1 arranged in parallel and three transverse connecting rods 10 hinged between the side support frames 1 . Eight openings 2 are arranged on the side support frame 1 , and cross blocks 3 are arranged in the openings 2 . Four clamping rods 5 for clamping the protruding iron of the truck are arranged on the support frame 1 on the outer side of the underframe 15 . Diagonal tie rods 8 are arranged between the clamping rods 5 and the outside of the bottom frame 15 , and reinforcing rods 9 are provided between the clamping rods 5 . The cross block 3 can block the movement of steel coils 14 of different widths through the openings 2 arranged at different positions. An anti-slip rubber pad 11 is provided on the contact surface between the bottom frame 15 and th...

Embodiment 2

[0024] See Figure 4 , Figure 5 , the second embodiment is basically the same as the first embodiment in structure, the difference is that there is one side support frame on the bottom frame 15 of the cross-bar type steel coil horizontal loading transport frame, and the cross-arm 12 is pierced, and the cross-arm 12 is arranged in the opening 2 on the side support frame 1 . Four side support frames 1 are arranged on the bottom frame 15 . Eight clamping rods 5 are arranged on the outer side support frame of the bottom frame 15 . Nine transverse connecting rods 10 are arranged between the support frame 1 on the upper side of the bottom frame 15 .

Embodiment 3

[0026] See Image 6 , Figure 7 , The fourth embodiment is basically the same as the second embodiment in structure, and the difference is that eight clamping rods 5 are arranged on the outer lateral connecting rods of the underframe 15 of the transverse steel coil horizontal loading transport frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com