Composite material for preparing infrared barrier polyester film and preparation method thereof

A composite material and polyester film technology, which is applied in the field of composite materials and their preparation, can solve the problems of difficult to meet the actual needs of weather resistance, difficulty in obtaining flatness products, complicated application process, etc., to achieve good infrared blocking effect and reduce blur Effect of fogging and simplification of film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

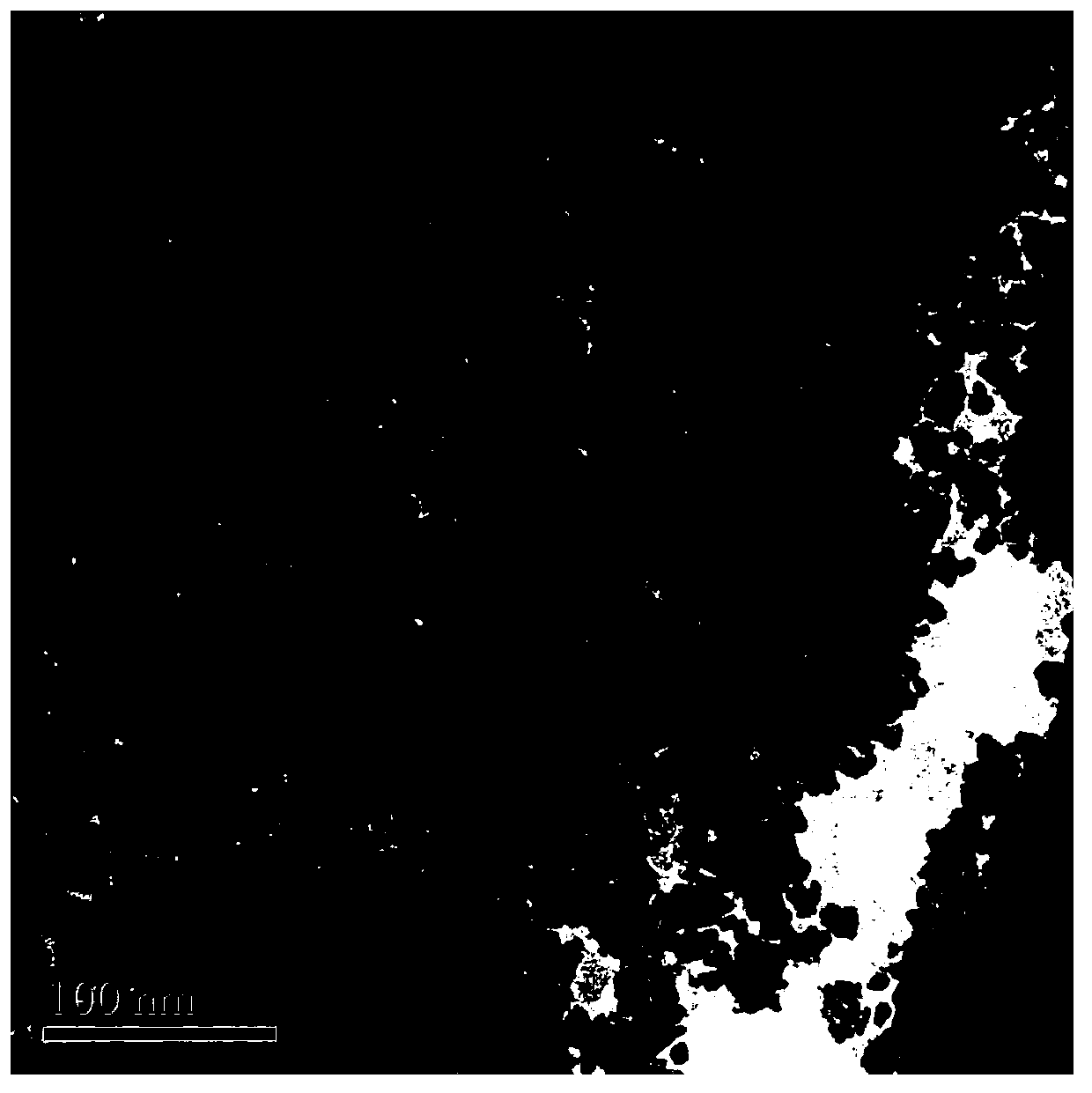

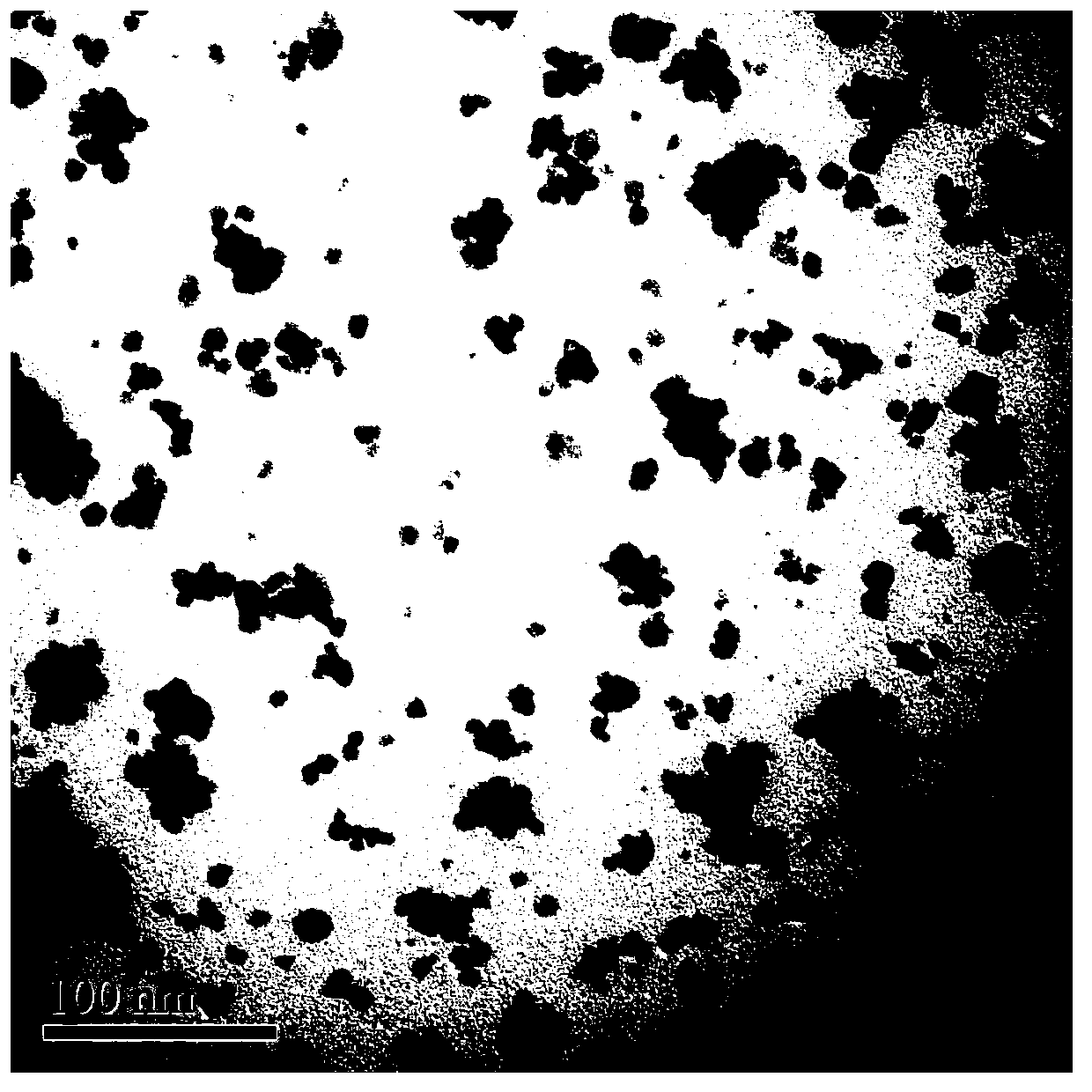

Image

Examples

Embodiment 2

[0030] Step 1: Put 25 kg of ethylene glycol into a 50-liter reactor 1, add 0.1 kg of titanate coupling agent isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, and then Add 1.5 kg of nano-titanium nitride powder, control the temperature of the reactor at 100°C, stir for 30 minutes with a high-shear machine at 3000 rpm, put it into a sand mill after processing, and add 1.5 kg Hydroxyl-containing acrylic resin was ground for 24 hours at a speed of 1000 rpm to obtain a nano-ceramic ethylene glycol dispersion and reserved for later use;

[0031] Step 2: Take 30 kilograms of dimethyl terephthalate and put it into a 100-liter reactor 2 with a cooling and reflux function, add the nano-ceramic ethylene glycol dispersion prepared in Step 1 into the reactor 2, and add antimony catalyst 0.5 liters. 008 kg, add 20 kg of ethylene glycol. Seal the reactor, fill it with inert gas nitrogen, heat to 160°C, heat and mix for about 30 minutes, then raise the temperature of the reactor to 22...

Embodiment 4

[0038]Step 1: Take 25 kg of ethylene glycol and put it into a 50-liter reactor 1, add 0.15 kg of titanate coupling agent isopropyl dioleate acyloxy (dioctyl phosphate acyloxy) titanium acid ester, then add 1 kg of ITO powder and 0.5 kg of AZO, control the temperature of the reactor at 100 ° C, stir with a high shear machine at 3000 rpm for 30 minutes, and put it into a sand mill after processing. Add 2 kilograms of carboxyl-containing acrylic resins, grind for 24 hours at a speed of 1000 rpm / min to obtain a nanoceramic ethylene glycol dispersion and keep it for later use;

[0039] Step 2: Get 30 kilograms of dimethyl terephthalate and put into 100 liters of reactor 2 with cooling and reflux function, add the nano ceramic ethylene glycol dispersion prepared in step 1 to reactor 2, add tin oxide catalyst 0 .02 kg, add 20 kg of ethylene glycol. Seal the reactor, fill it with inert gas nitrogen, heat to 160°C, heat, stir and mix for about 30 minutes, then raise the temperature of...

Embodiment 5

[0042] Step 1: Put 25 kg of ethylene glycol into a 50-liter reactor 1, add 0.08 kg of silane coupling agent 3-methacryloxypropyltrimethoxysilane), and then add 1 kg of nano Titanium nitride and 0.5 kg of nano-lanthanum hexaboride powder mixture, the temperature of the reaction kettle is controlled at 100 ° C, stirred with a high shear machine at 3000 rpm for 30 minutes, and put into a sand mill after processing. Add 1 kg of carboxyl-containing vinyl resin, grind at a speed of 900 rpm for 24 hours to obtain a nano ceramic ethylene glycol dispersion and reserve it for subsequent use;

[0043] Step 2: Take 30 kilograms of dimethyl terephthalate and put it into a 100-liter reactor 2 with a cooling and reflux function, add the nano-ceramic ethylene glycol dispersion prepared in Step 1 into the reactor 2, and add antimony catalyst 0.5 liters. 005 kg, add 20 kg of ethylene glycol. Seal the reactor, fill it with inert gas nitrogen, heat to 160°C, heat, stir and mix for about 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com