Liquid passing type electric-control layered polymer filling device

A technology of injector and polymer, which is applied in the direction of mining fluid, measurement, wellbore/well parts, etc., can solve the problems of low work efficiency, large viscosity loss, and inability to adjust continuously, so as to achieve good sealing effect and balance internal and external pressure Poor, precisely measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

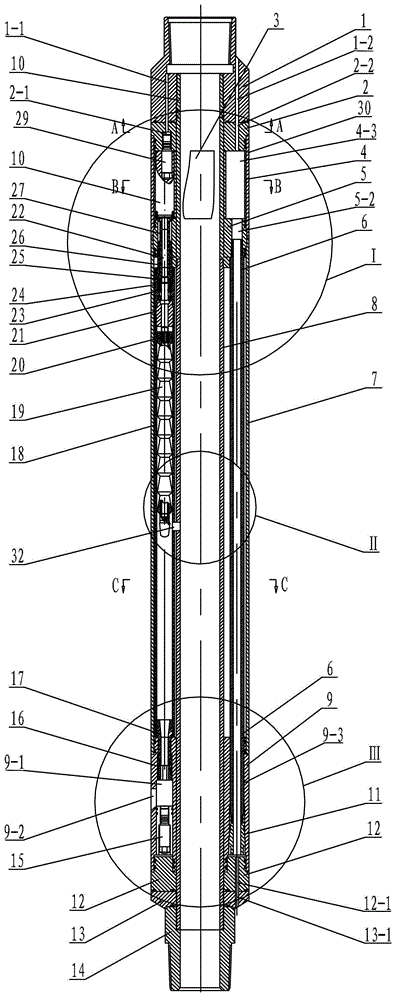

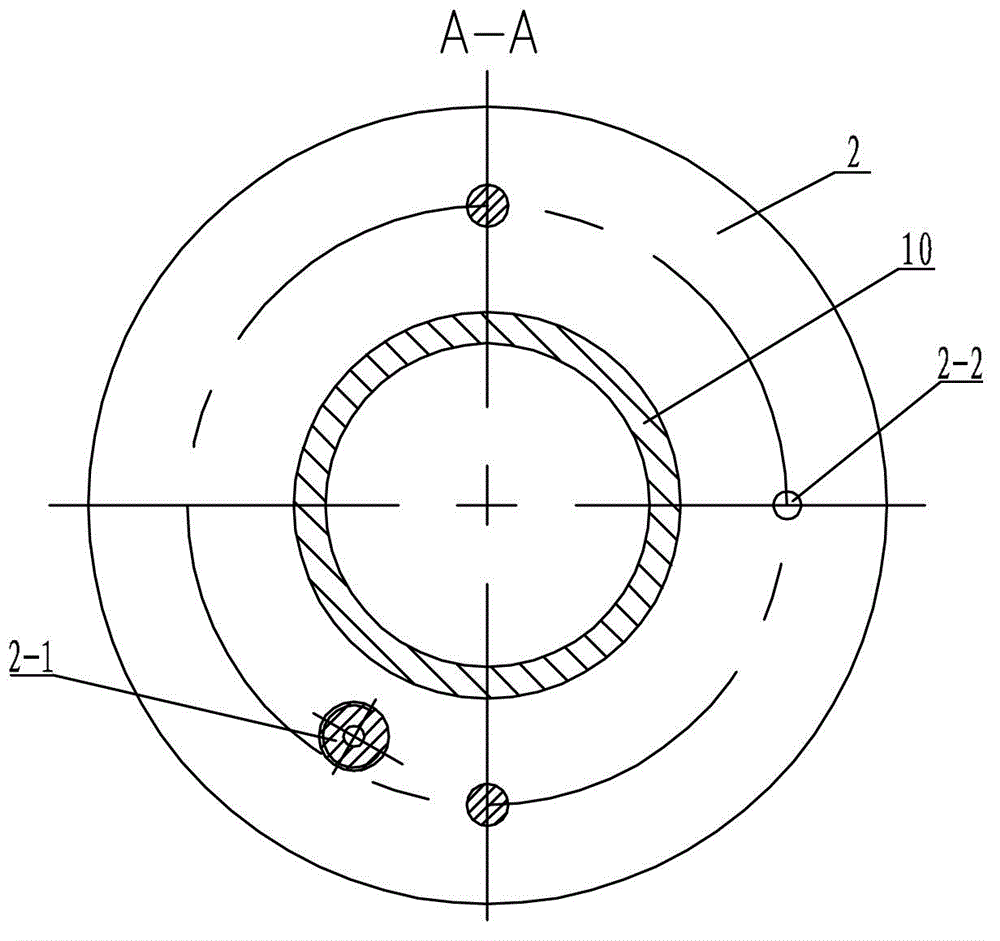

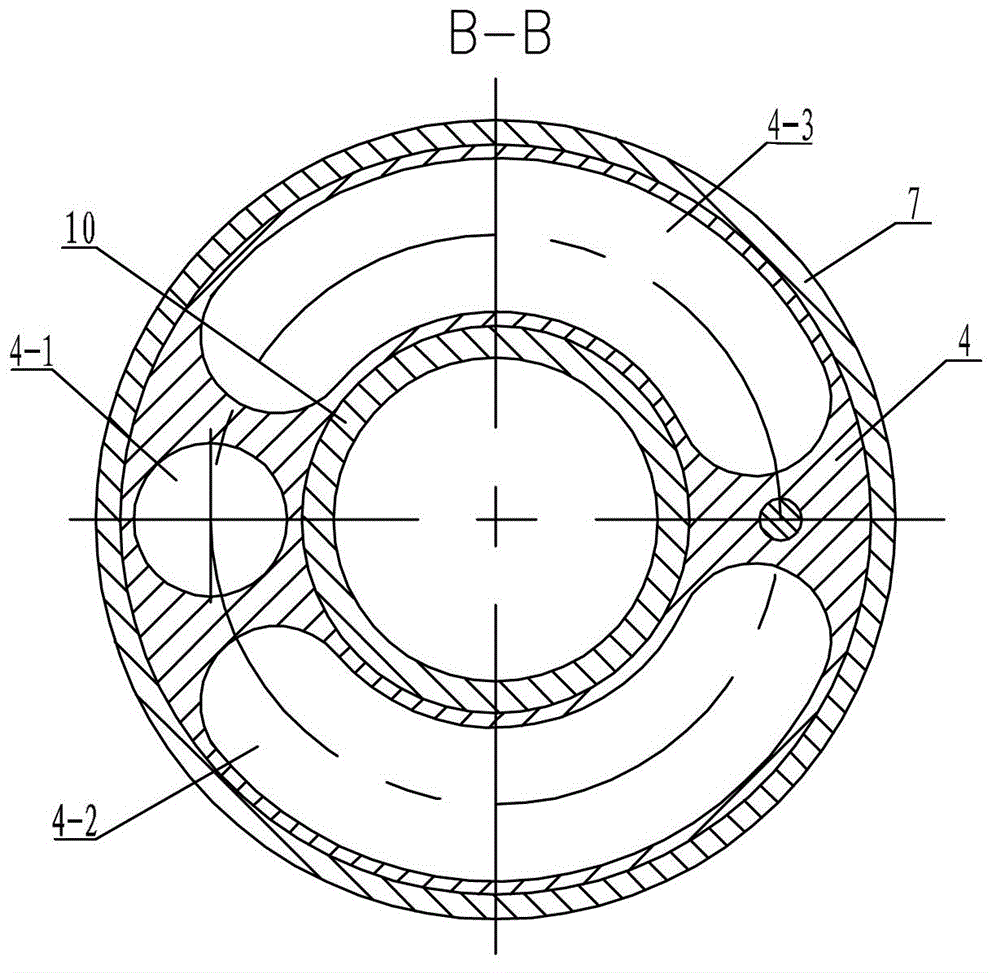

[0009] Specific implementation mode one: combine Figure 1 to Figure 7 This embodiment is described. The liquid-type electronically controlled layered polymer dispenser of this embodiment includes an upper joint 1, a cable sealing body 2, a circuit board 3, a motor casing 4, an output shaft connector 5, and a cable casing 6 , the lower outer protective shell sleeve 7, the lower central tube 8, the bottom cable joint body 9, the upper central tube 10, the lower cable sealing body 11, the bottom cable housing 12, the lower compression sealing body 13, the locking nut joint 14, Lower pressure sensor 15, bottom spool sealing body 16, water blocking body 17, spool body 18, spool 19, screw nut 20, rotating sealing body 21, screw rod 22, bearing assembly 23, bearing sleeve 24, lock nut 25. Screw end connecting body 26, coupling 27, motor reducer 28, upper outer protective shell 30 and anti-rotation body 31, the upper central tube 10 and the lower central tube 8 are set up and down, a...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 , Figure 5and Figure 7 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that it also adds upper pressure sensor 29, is provided with solution through hole 1-1 on the side wall of upper connector 1, and the solution through hole 1-1 The upper end communicates with the central hole of the upper joint 1, and the cable sealing body 2 is provided with an upper pressure sensor installation hole 2-1 communicated with the solution through hole 1-1, and the lower end of the upper pressure sensor installation hole 2-1 is a threaded hole, the pressure The lower end of the sensor mounting hole 2-1 communicates with the circuit board hole 4-2, the upper pressure sensor 29 is arranged in the circuit board hole 4-2, and the upper end of the upper pressure sensor 29 is threaded with the lower end of the upper pressure sensor mounting hole 2-1 connect. The polymer solution in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com