Method for reducing working blind zone of ultrasonic transducer on the basis of excitation energy control

A technology of working blind area and exciting energy, applied in the re-radiation of sound waves, instruments, measuring devices, etc., can solve problems such as inconvenience in measurement, and achieve the effect of broadening the range, reducing the working blind area, and reducing the installation distance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

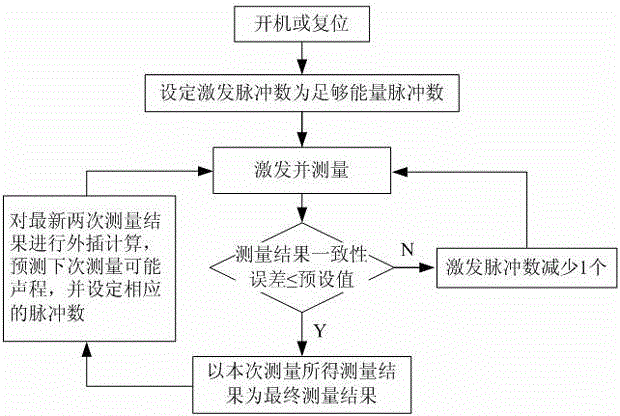

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

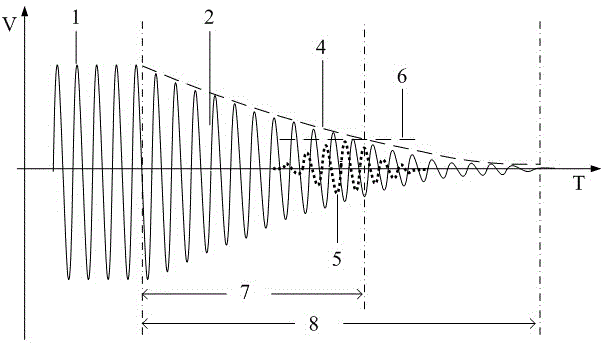

[0022] Such as figure 1 Shown is a schematic diagram of the working blind area of the ultrasonic transducer. The frequency of the ultrasonic excitation signal 1 is the same as the resonance frequency of the ultrasonic transducer. Therefore, after the ultrasonic excitation signal 1 enters the ultrasonic transducer, it can cause the ultrasonic transducer to resonate and excite the ultrasonic excitation signal. However, when the ultrasonic excitation signal 1 disappears, due to the residual energy during the excitation, the energy conversion element inside the ultrasonic transducer will continue to vibrate due to mechanical inertia and electrical inertia (free decay oscillation), resulting in aftershock signal 2. From the amplitude envelope 3 of the aftershock signal, it can be seen that the vibration of the aftersh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com