Drying device for electrodeless lamp

A technology of baking device and electrodeless lamp, which is applied in the direction of electric tube/lamp exhaust, etc., can solve the problem of different baking effect of lamp tube, and achieve the effect of uniform baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

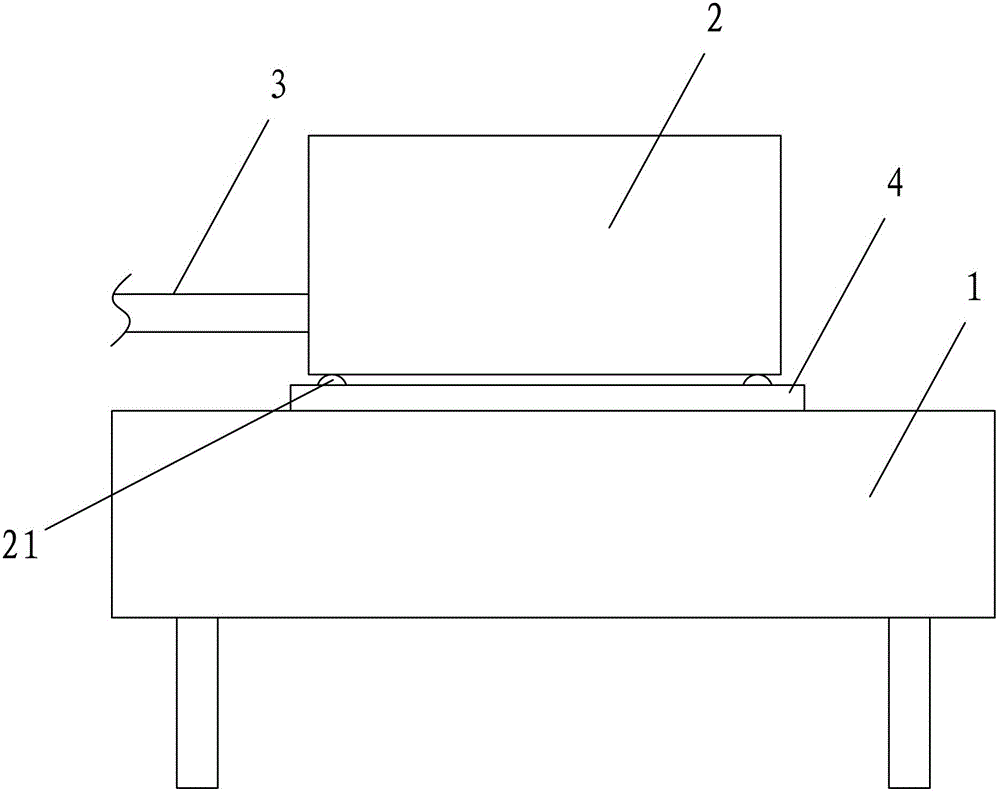

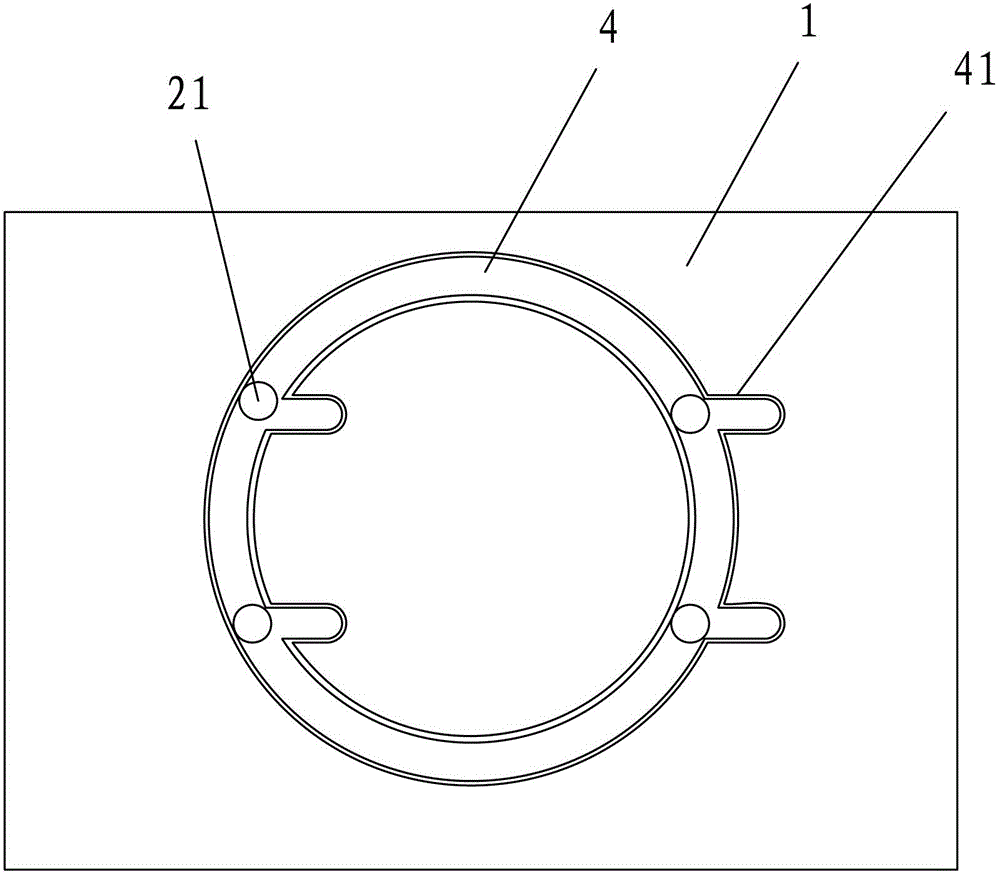

[0015] An electrodeless lamp baking device, comprising a workbench 1, an oven 2, and a feeding track 3.

[0016] The oven 2 is used for drying the cabinet of the electrodeless lamp, and the oven 2 adopts an internal heating method. The structural principle of the oven itself is a conventional technical means in the field, and will not be described here.

[0017] In this embodiment, the two ends of the oven 2 pass through the oven body. The traditional baking method is to arrange a through track in the oven 2, and the electrodeless lamp enters from one end and exits from the other end. In the present invention, the feeding track 3 is a track of a telescopic structure, and is only arranged at one end of the oven 2 . In this way, the electrodeless lamp tube is placed on the feeding track 3, and the electrodeless lamp tube is sent into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com