Offshore vessel for laying a pipeline on the seabed, and a method for handling pipe sections

A technology for pipeline departments and ships, applied in pipe laying ships, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as unsatisfactory pipeline sections, and achieve the effect of fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

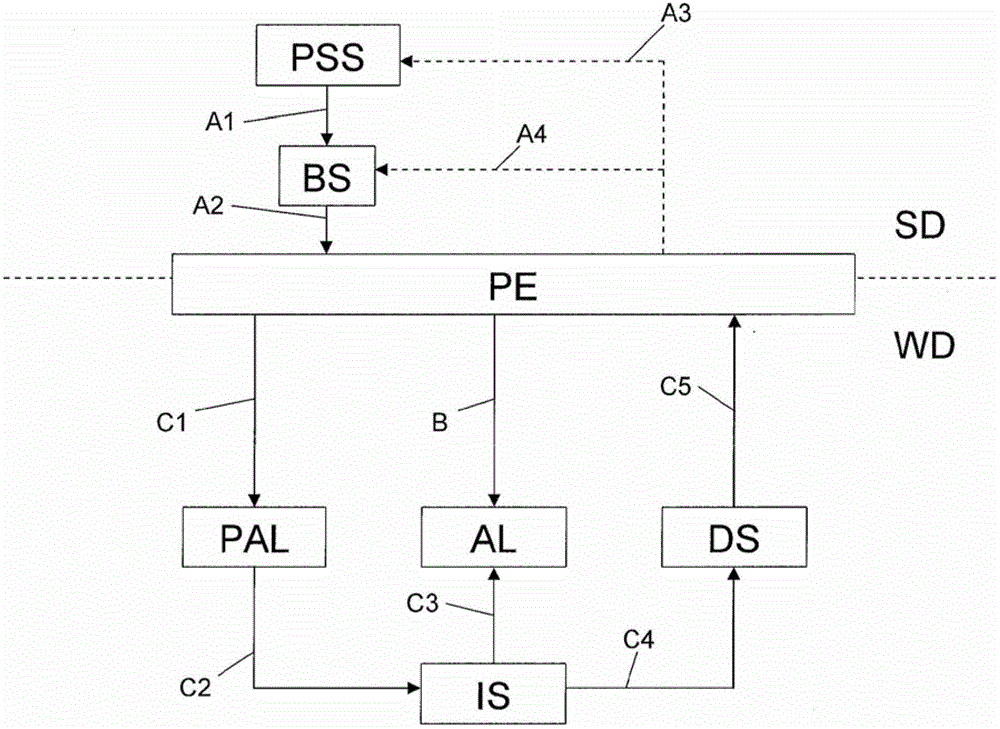

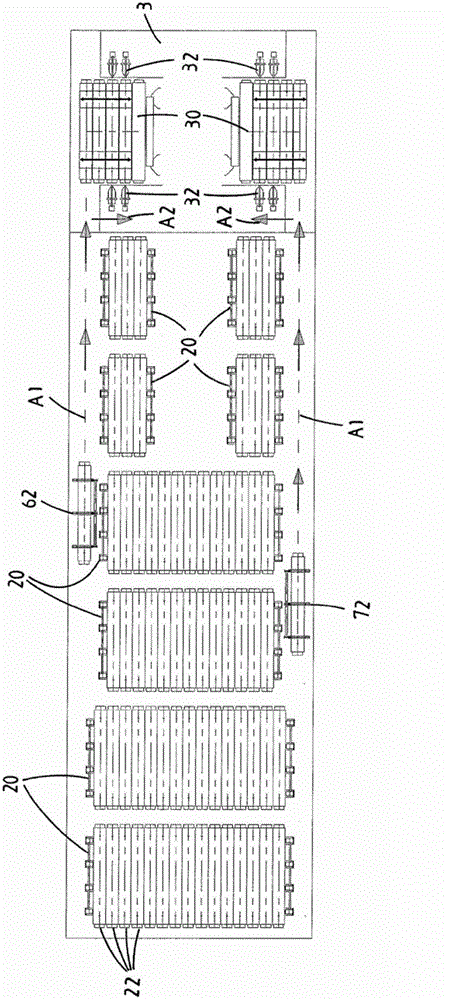

[0045] figure 1 A schematic block diagram of a pipeline laying device according to an embodiment of the present invention is shown. The pipeline laying apparatus comprises a pre-assembly line PAL for joining single pipe sections end-to-end to form multi-section pipe sections, an inspection station IS associated with the pre-assembly line PAL for inspecting seams), an assembly line AL for assembling the pipeline to be launched from a vessel (not shown), and a transporter system for transporting multi-section and single-section pipeline sections.

[0046] The conveyor system includes an access point, which in this embodiment is in the form of a pipe elevator PE. The transporter system is configured to allow transport of multi-segment and / or single-segment pipeline segments along at least the following routes:

[0047] - Route B: direct transport from pipe lift PE to assembly line AL;

[0048] - Route C1-C2-C3: indirect transport from pipe lift PE to assembly line AL via pre-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com