Casting mold structure and base plate applicable to medium and large-scale vertical centrifugal casting machines

A centrifugal casting machine and vertical centrifugal technology, which is applied in the field of mold structure and chassis, can solve the problems of poor mold reusability and high cost, and achieve the effects of comprehensive cost reduction, high reuse rate, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0022] A large vertical centrifugal casting machine model J5520B, the power of the main motor is 75kW, the maximum speed of the main shaft is 500rpm, and the speed can be adjusted steplessly. This equipment is suitable for single piece and small batch production. The size range of castings produced by this centrifugal casting machine: the maximum outer diameter is Ф2000mm, the maximum height is 500mm, and the load capacity of the centrifuge chassis is W (W 铸件 +W 铸型 ) within 10t.

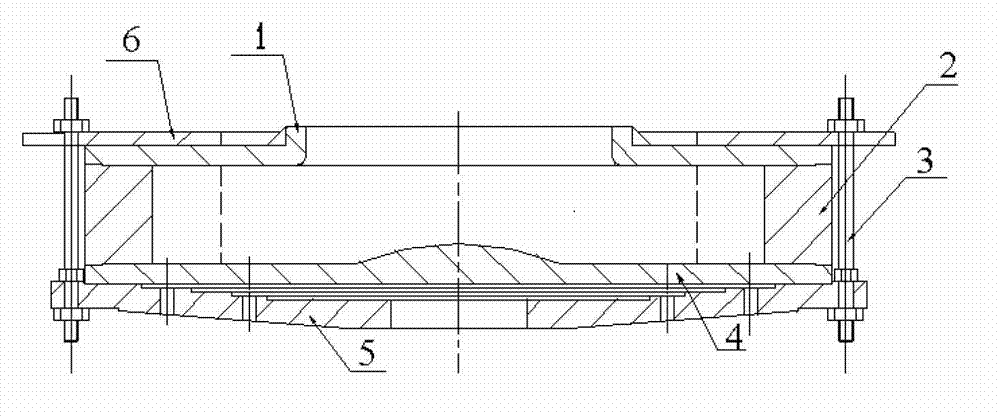

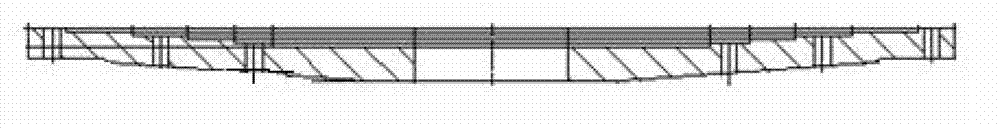

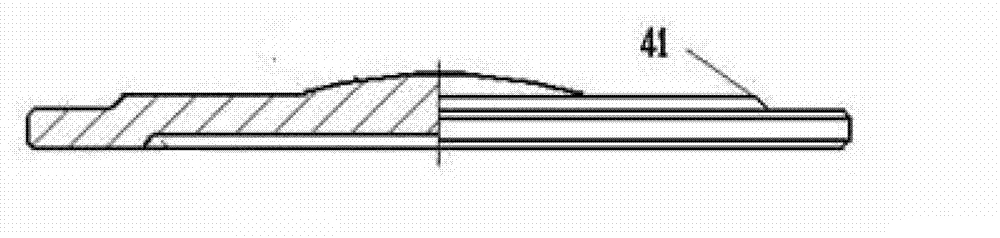

[0023] Such as figure 1 The casting mold structure shown includes three parts: the base plate 4 , the cover plate 1 and the metal sleeve 2 , and the casting mold structure is positioned and locked on the chassis 5 of the vertical centrifugal casting machine. The mold structure is integrally locked on the centrifugal casting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com