Hydraulic tensioner with safe pressure relief device

A technology of hydraulic tensioner and pressure relief device, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high production cost and complex structure, achieve convenient operation, reduce friction, and avoid spiral displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

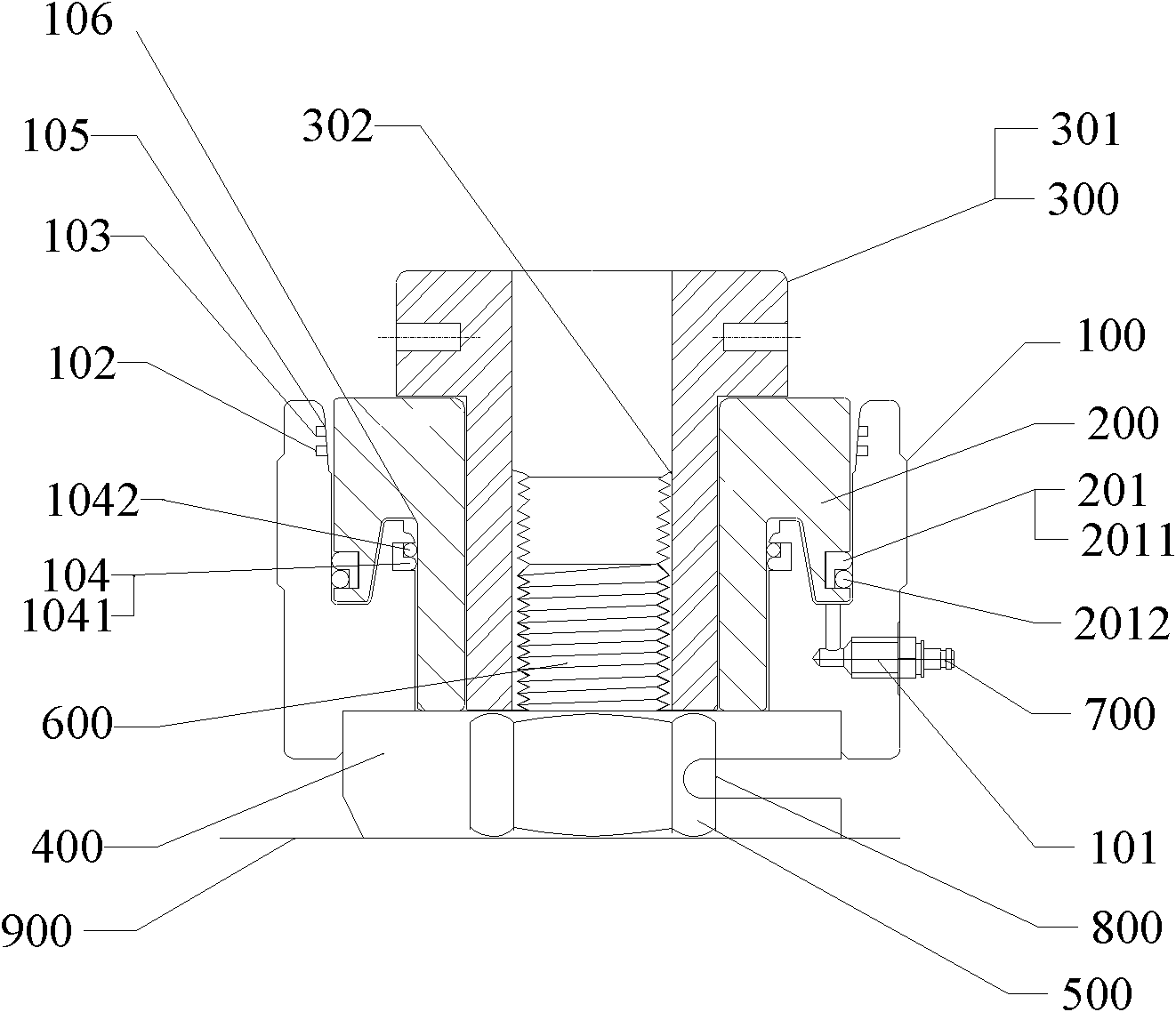

[0027] see figure 1 The hydraulic tensioner with a safety pressure relief device of the present invention includes a hydraulic cylinder 100, a piston 200, a tensioning member 300, a support bridge 400, a quick connector 700, and a dial ring 800. The support bridge 400 is arranged on the surface of the connected workpiece 900, The hydraulic cylinder 100 is fixed on the support bridge 400 . The piston 200 is socketed in the hydraulic cylinder 100 , the external structure of the piston 200 matches the internal structure of the hydraulic cylinder 100 , and a through hole is arranged in the center of the piston 200 . The stretching head 301 of the stretching member 300 is arranged on the upper end surface of the piston 200, and the stretching rod 302 is arranged in the through hole of the piston 200. The inner diameter of the stretching rod 302 is adapted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com