Mounting and clamping dual-purpose knife set for facing head machining

A technology of flat rotating disc and knife sleeve, which is applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of difficult machining of the inner cavity of the steam turbine, the incompatibility of the knife sleeve, and the poor adaptability, etc. Low cost, simple structure and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

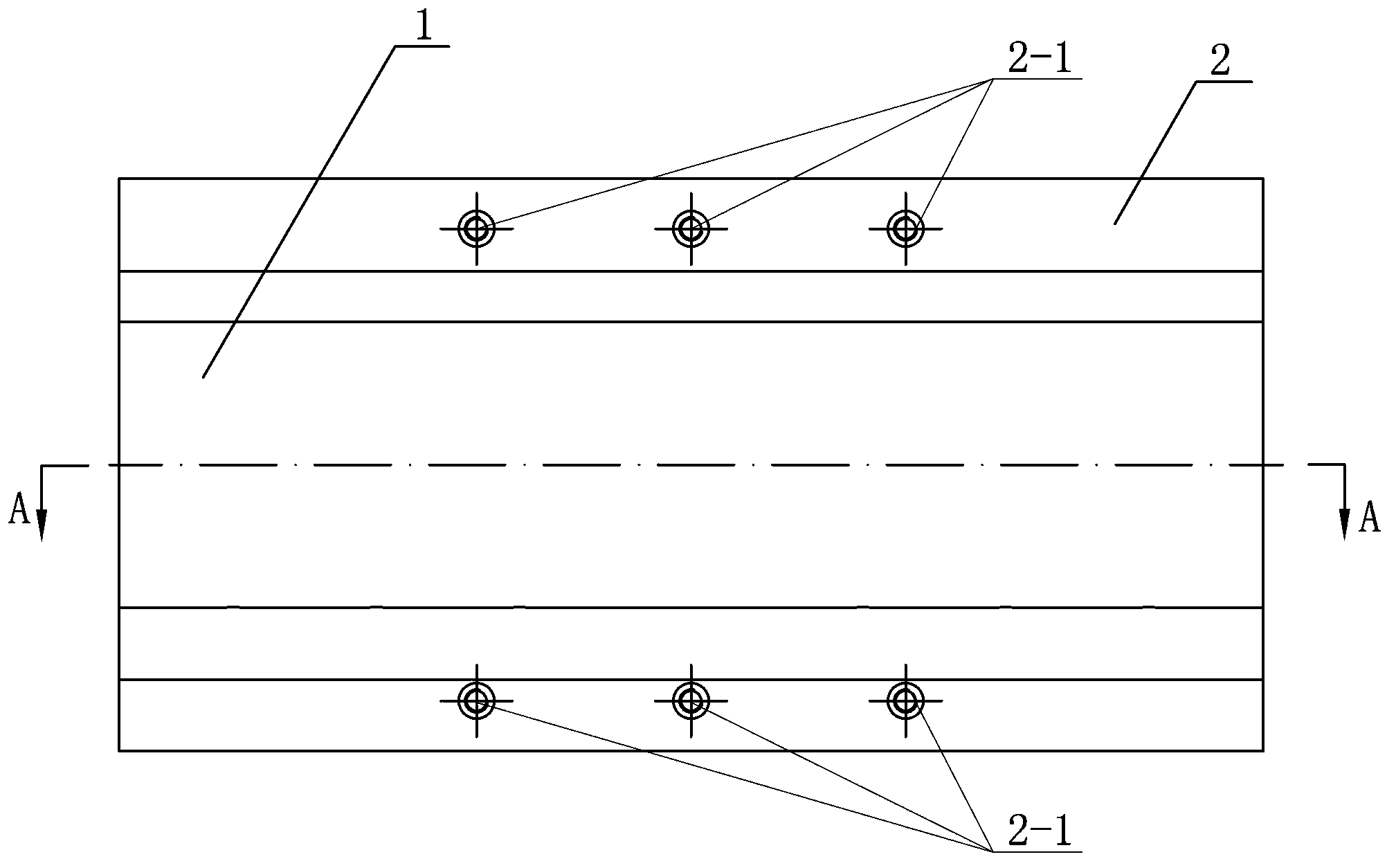

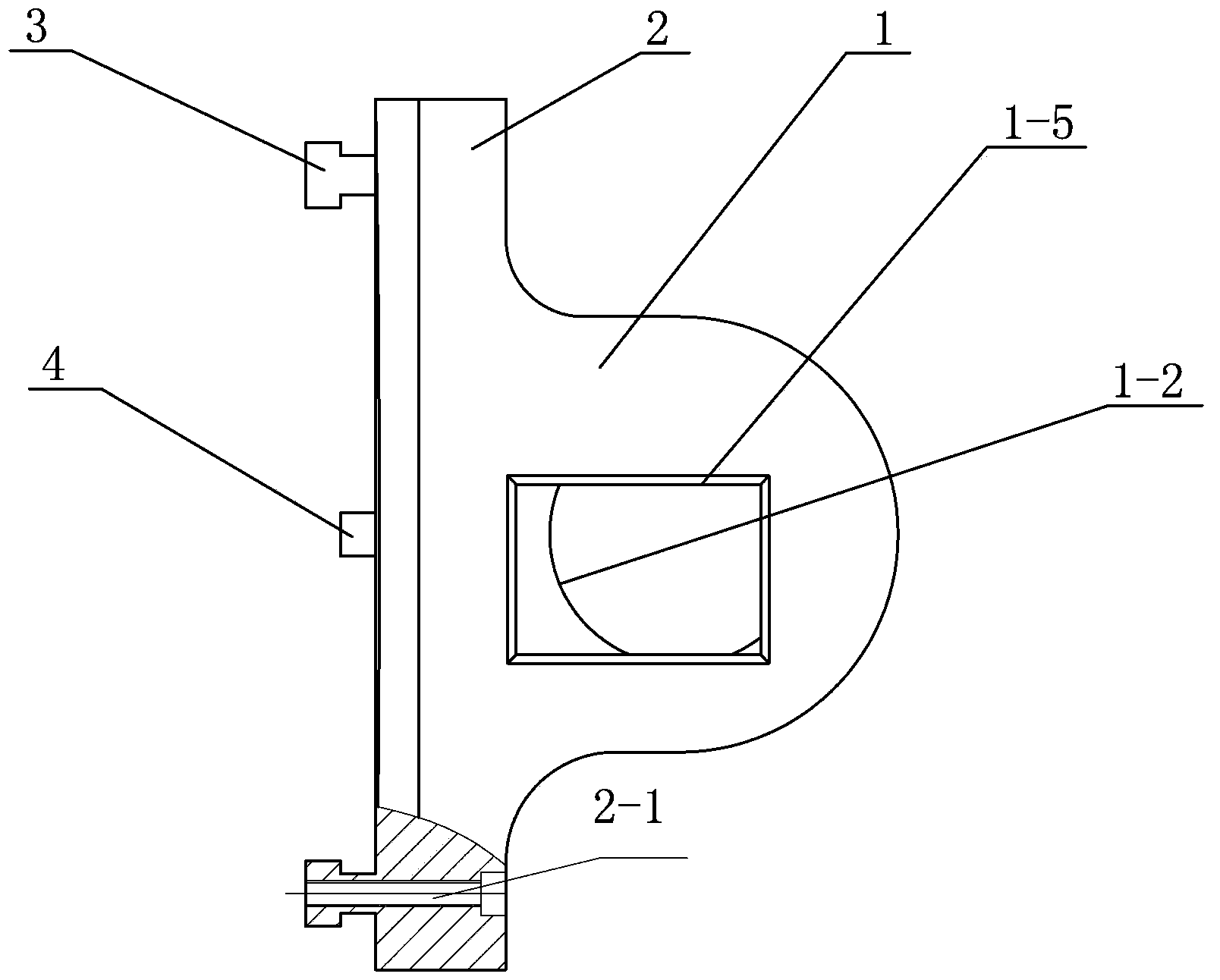

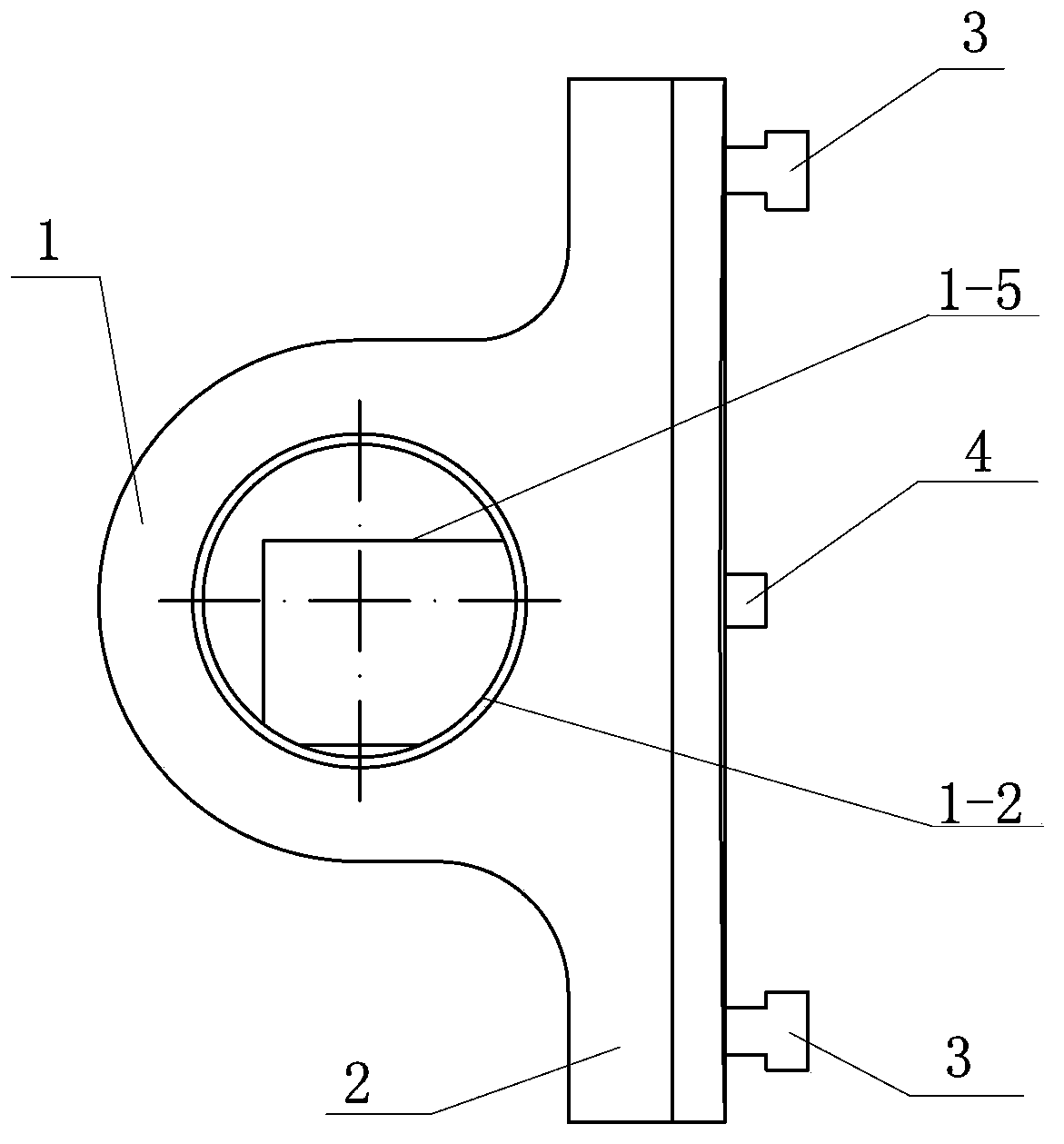

[0008] Specific implementation mode 1: Combination Figure 1-Figure 5 Explain that a clamping dual-purpose tool holder for flat-rotating disk processing in this embodiment includes a cylinder 1, an octahedron 2, two connecting bodies 3, and two shank keys 4;

[0009] The cross-sectional shape of the shank key 4 is a waist shape, the longitudinal section of the connecting body 3 is a T-shape, the octahedron 2 is a longitudinal cross-sectional shape of an octahedron with a rectangular upper end and an isosceles trapezoid at the lower end, etc. The long base side of the waist trapezoid is coplanar with the long side of the rectangle. The cylinder 1 has round holes 1-2 along its axial direction from one end face to the radial center line MN. The round holes 1-2 are used for installation. Tool holder, the cylinder 1 is machined with rectangular holes 1-5 along its axial direction from the other end surface to the radial center line MN. The rectangular holes 1-5 are used to install the...

specific Embodiment approach 2

[0010] Specific implementation manner two: combination Figure 4 To illustrate this embodiment, the knife sleeve of this embodiment also includes four first screws 5, each shank key 4 is provided with two first through holes 4-1, and the upper end surface of the octahedron 2 is connected to each A first threaded hole 2-2 is provided at a position corresponding to a through hole 4-1, and each shank key 4 and the octahedron 2 are provided in the first through hole 4-1 and connected with the first threaded hole 2-2. The threaded first screw 5 can be detachably connected. With this setting, the connection is efficient and reliable, meeting actual needs and design requirements.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 , figure 2 with Figure 5 To describe this embodiment, each connecting body 3 and the octahedron 2 described in this embodiment are coaxially provided with a second threaded hole 2-1. This arrangement facilitates the insertion of screws, which are tightened into the grooves of the machine tool pan through the screws, and facilitates the secure connection between the tool sleeve of the present invention and the machine tool pan. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com