Device and method for winding sheet of material

A kind of equipment and reel technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem that the winding equipment cannot reach the natural frequency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

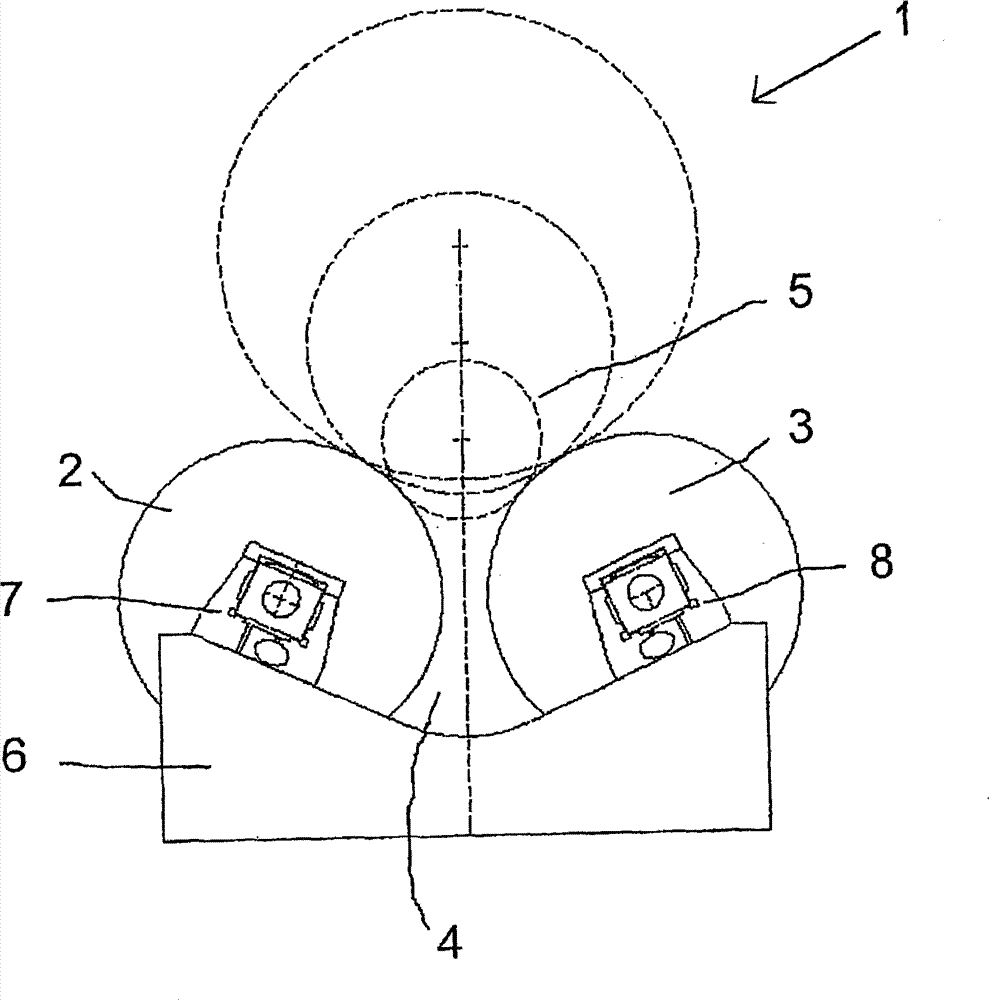

[0034] figure 1 The winding device 1 is shown very clearly in the form of a double backup roll coiler. The winding device 1 has two drum-type support rolls 2, 3, between which a winding bed 4 is formed, in which a schematically shown mandrel 5 is arranged, in which A material web, not shown in detail, is wound up on the mandrel 5 . The construction of such double backup roll coilers is known per se.

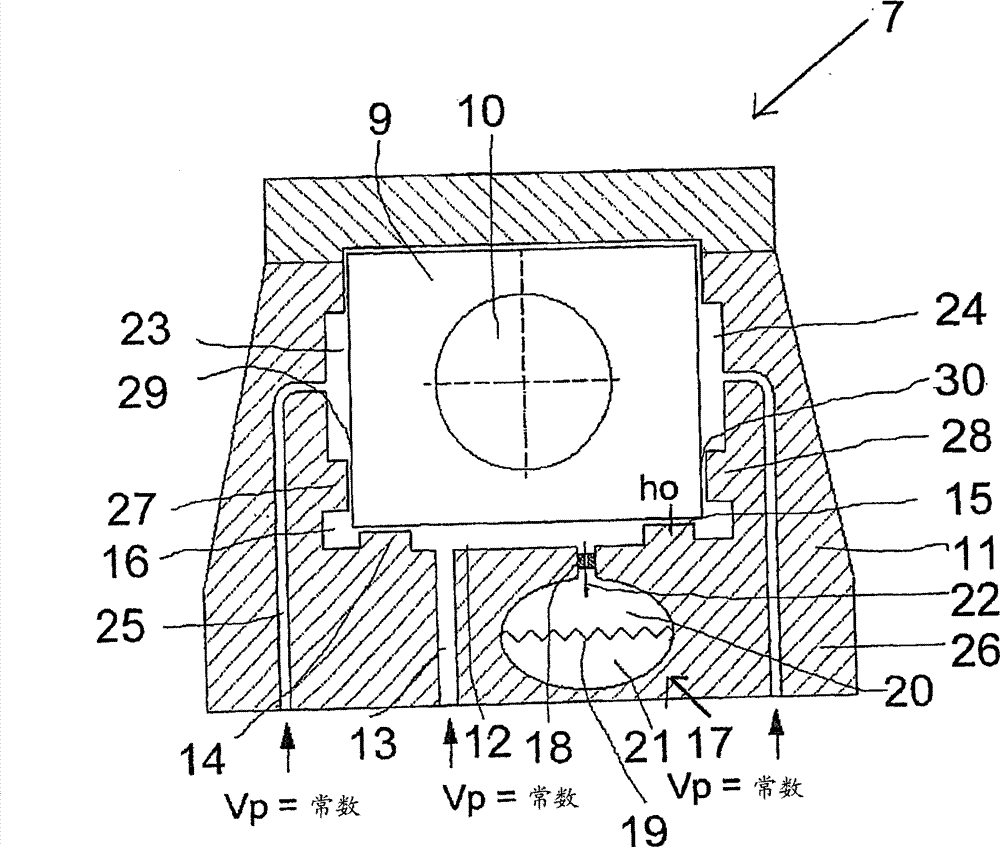

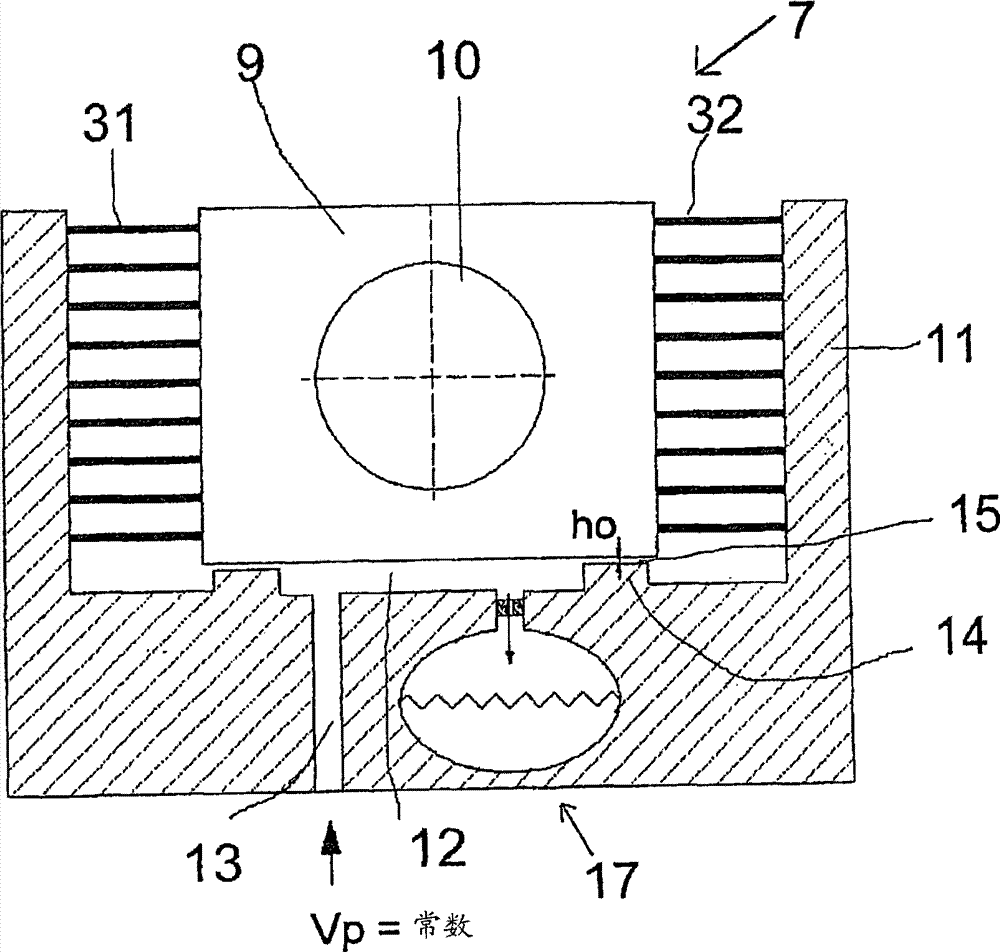

[0035] The two support rollers 2 , 3 are supported on a machine frame 6 . Accordingly, each backup roll 2, 3 has a bearing arrangement with a bearing 7, 8 on each roll end. figure 1 Only a single bearing 7, 8 is shown respectively.

[0036]This coiling device can run at maximum input speed. The input speed is, for example, 2500 m / min or 3000 m / min. A certain number of revolutions and thus a certain rotational frequency of the support rollers 2 , 3 can thus be achieved. The winding device is configured for this rotational frequency. When the winding process starts, the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com