Axle steel used for railway car and production process thereof

A manufacturing process and technology for railway vehicles, applied in the field of material processing, can solve problems such as insufficiency, and achieve the effects of fine grain structure, low gas content and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

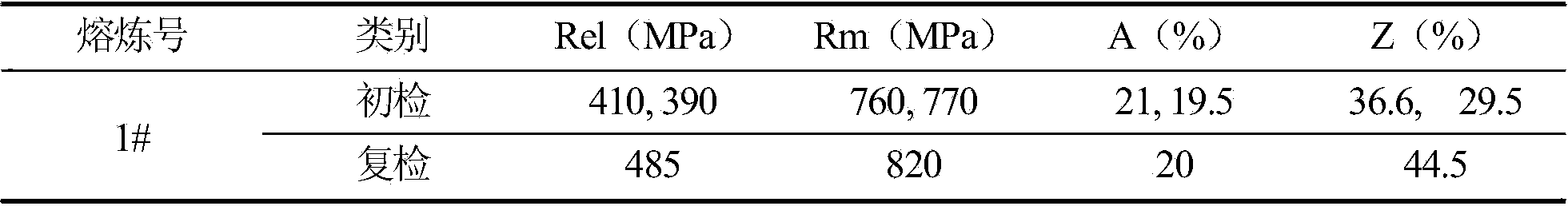

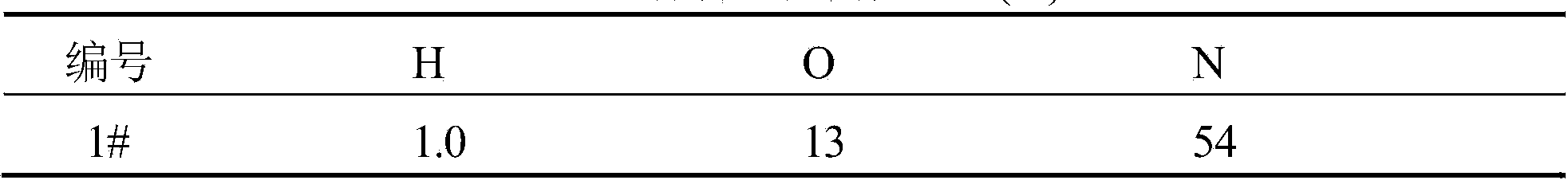

Embodiment 1

[0010] The chemical composition of molten steel is calculated by weight percentage: C0.55%, Si0.23%, Mn0.72%, P0.017%, S0.005%, Cr0.04%, Ni0.01%, Cu0.01 %, Alt0.045%, and the rest are Fe and undetectable trace impurities. Converter molten steel is refined by LF furnace and the adjusted composition is: C0.53%, Si0.23%, Mn0.70%, P0.015%, S0.005%, Cr0.04%, Ni0.01%, Cu0 .01%, Alt 0.049%, the rest is Fe and undetectable trace impurities. After refining, feed aluminum wire 400mm for further deoxidation. After refining, the molten steel is sent to VD furnace for vacuum degassing, the vacuum degree is 0.041kPa, and the deep vacuum time is 13min. Molten steel is mold-cast into steel ingots, heated in a soaking furnace for preliminary rolling and slow cooling. The temperature of the soaking furnace is 867°C, and the billet is initially rolled into a non-cut billet. The billet enters the slow cooling pit at a temperature of 620°C and exits for slow cooling The pit temperature is 270°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com