Softener product raw material and method for preparing softener product

A softener and product technology, applied in the field of softeners, can solve problems such as instability, large viscosity deviation, complex production process, etc., to achieve the effects of avoiding unstable viscosity, simplifying the production process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Softener product raw material preparation

[0044] Dioctadecyl dimethyl ammonium chloride raw material was sliced at a temperature of 25°C (the size of the slice was not more than 2×2cm, and the thickness was not more than 1mm), and polyethylene glycol was added in proportion (95:5) -150 bis-stearic acid solid (powder, molecular weight 6000), ready for use after simple mixing.

[0045] Softener product preparation

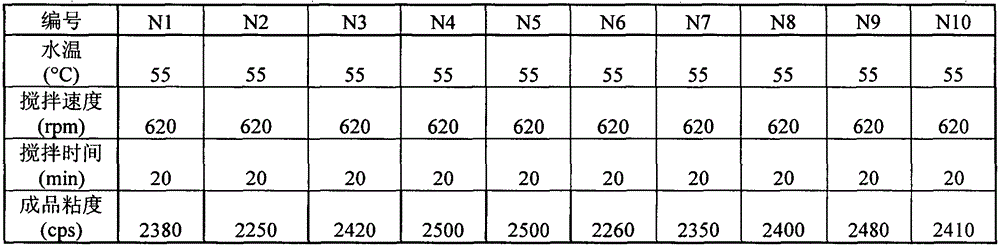

[0046] Control the water temperature at 55°C, add 0.15% of the total amount of softener to the finished product, and add 1% pigment (solvent is water), disperse completely, and keep the water temperature at 55-60°C during this period, then add the softener while stirring The total amount of the finished product is 5% of the raw materials of the above softener product. Stir while using a water bath of 55°C-60°C to keep the temperature at about 55-60°C. After stirring and dispersing completely, cool down to 25°C and add essence. Detect its viscosity, with ...

Embodiment 2

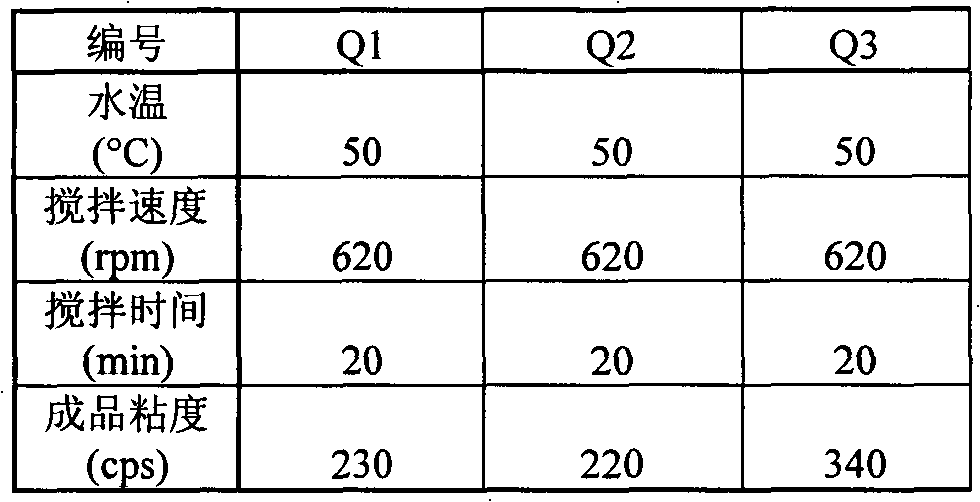

[0057] Prepare 3 parts of softener raw materials according to the same proportioning and process as in Example 1.

[0058] Control the water temperature at 50°C, add 0.15% of the total amount of the finished softener and add 1% of the pigment (solvent is water), and disperse completely. During this time, the water temperature remains at 50°C, and then add 0.15% of the total amount of the softener. For softener product raw materials with an amount of 5%, keep the temperature at 50°C while stirring. After stirring and dispersing completely, cool down to 25°C and add essence. Detect its viscosity, with a viscosity of 1800-2500 as a qualified product.

[0059] Process parameter and viscosity of table 4 embodiment 2 products

[0060]

[0061] The raw materials of M1, M2 and M3 are prepared in the same way as the raw materials used in Example 1. After lowering the water temperature, the viscosity of the softener finished product does not change significantly, and is within the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com