Concrete cable channel construction process

A kind of construction technology and concrete technology, which is applied in the installation of cables, ground cables, artificial islands, etc. It can solve the problems of easy deformation, complicated installation process, and insufficient tight joints of formwork, and achieve the effect of not easy deformation and tight splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific examples.

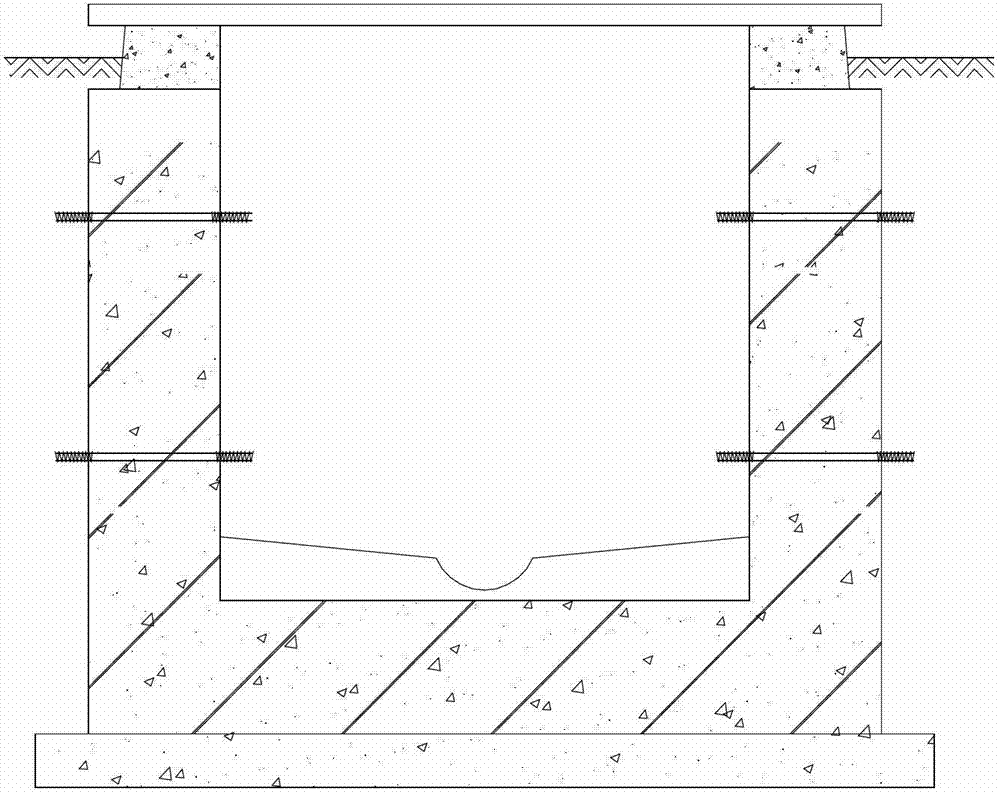

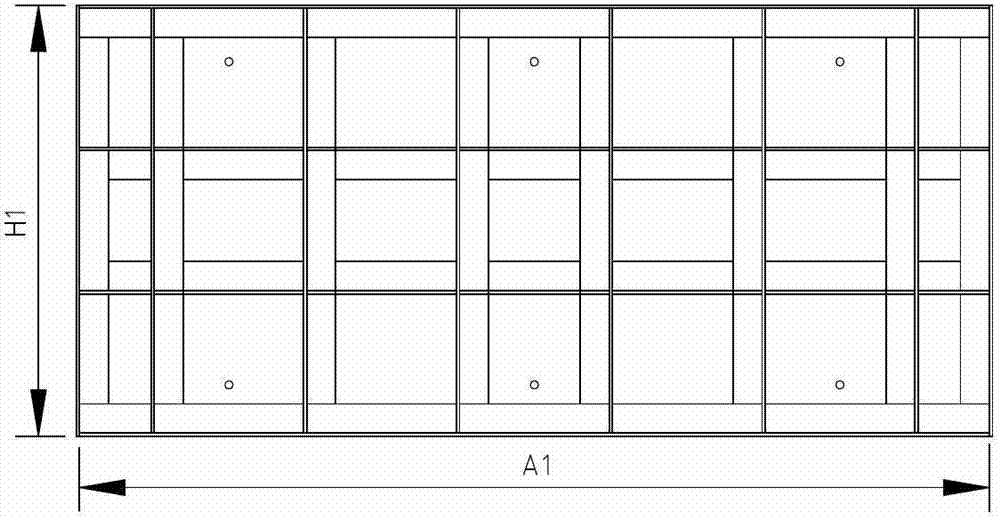

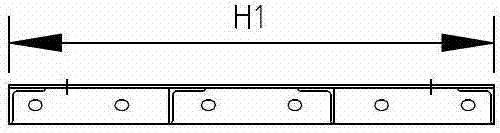

[0026] see figure 1 , in order to overcome the shortcomings of the traditional construction technology in the background technology, the present invention provides an improved concrete cable trench construction process, design and manufacture steel formwork for combined assembly and use pull bolts to control the thickness of the cable trench, which can It is suitable for the construction of concrete cable trenches in substations (converters) of different voltage levels. The concrete technological process of the concrete cable trench construction technology of preferred embodiment of the present invention will be introduced in detail as follows:

[0027] Before the construction of the project, the overall planning shall be carried out according to the layout of the cable trench in the station and the design characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com