Assembly type aluminum alloy form arranged at post-cast strip and construction joint positions

A technology of aluminum alloy formwork and construction joints, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, construction, etc., which can solve unfavorable cost savings, reduce the mechanical performance of structural plates, and reduce structural durability To avoid concrete grout leakage, ensure the durability of the structure, and ensure the quality of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

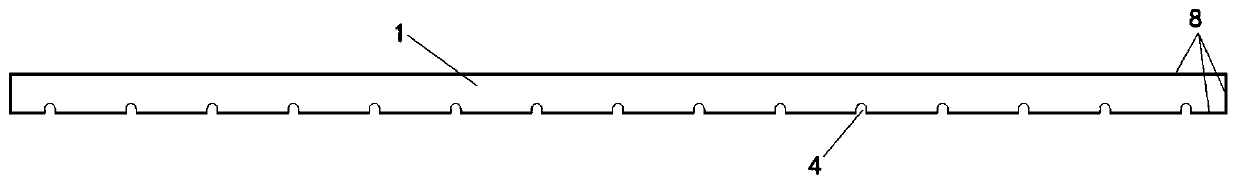

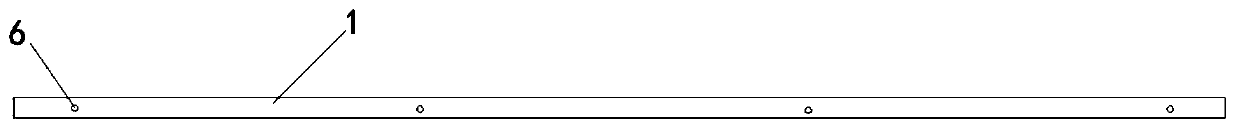

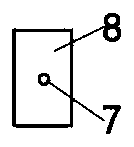

[0038] Such as Figure 1-10 As shown, the present invention relates to a post-casting belt and an assembled aluminum alloy formwork at the construction joint position, including a gluten formwork 1, a web formwork 2 and a bottom reinforcement formwork 3 all made of aluminum alloy materials, and the bottom reinforcement formwork 3 The upper end of the upper end is provided with a plurality of lower U-shaped grooves 5 with openings upward for the bottom rib to pass through, the web template 2 is installed on the upper end of the bottom rib template 3, and the lower end of the gluten template 1 is provided with a plurality of An upper U-shaped groove 4 with an opening downward for gluten to pass through, and the gluten template 1 is installed on the upper end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com