Swelling technology for carrying out fracturing construction on fiber

A technology of fiber and technology, which is applied in the field of oil and gas development and fracturing construction, can solve the problems of non-filament fiber, no technical exchange outside, and no patent application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

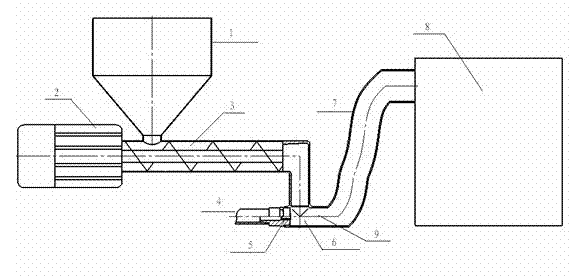

[0015] Such as figure 1 As shown, the puffing technology device for fracturing construction fibers, which includes fiber hopper 1, variable frequency adjustable speed motor 2, metering screw pump 3, air jet mixer 6, bellows 7, restrictor 5 and fracturing mixing tank 8.

[0016] The left end of the metering screw pump 3 is fixed and connected to the adjustable-speed variable-frequency motor 2 through screws, and the adjustable-speed variable-frequency motor 2 drives the metering screw pump 3 to measure and control the amount of fiber added to achieve different amounts The requirement of uniform speed can be achieved under any circumstances to ensure the stability of the puffing effect. The speed control range of the variable frequency adjustable speed motor 2 is 1 to 10 L / min.

[0017] The hopper mouth of the fiber hopper 1 is welded and connected to the input port above the left end of the casing of the metering screw pump 3; the fiber hopper 1 is a feeding hopper, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com