BP (Back Propagation) neural network based high-precision correction and test method for resonance cylinder pressure sensor

A BP neural network and pressure sensor technology, applied in biological neural network models, measuring fluid pressure, instruments, etc., can solve the problem that the fitting accuracy cannot meet the accuracy requirements, solve the problem of high-precision calibration and test, enhance the approximation ability, The effect of improving the fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following describes the high-precision calibration method of the resonant cylinder pressure sensor based on the BP neural network provided by the present invention in conjunction with the drawings and embodiments:

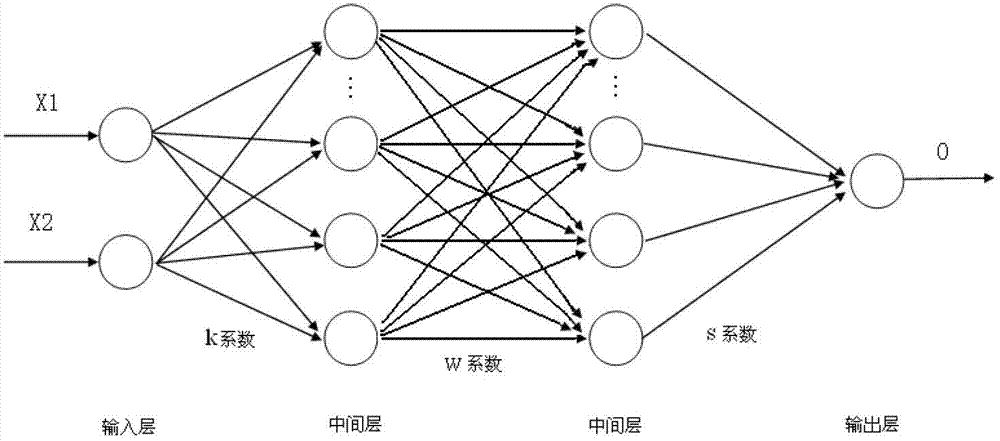

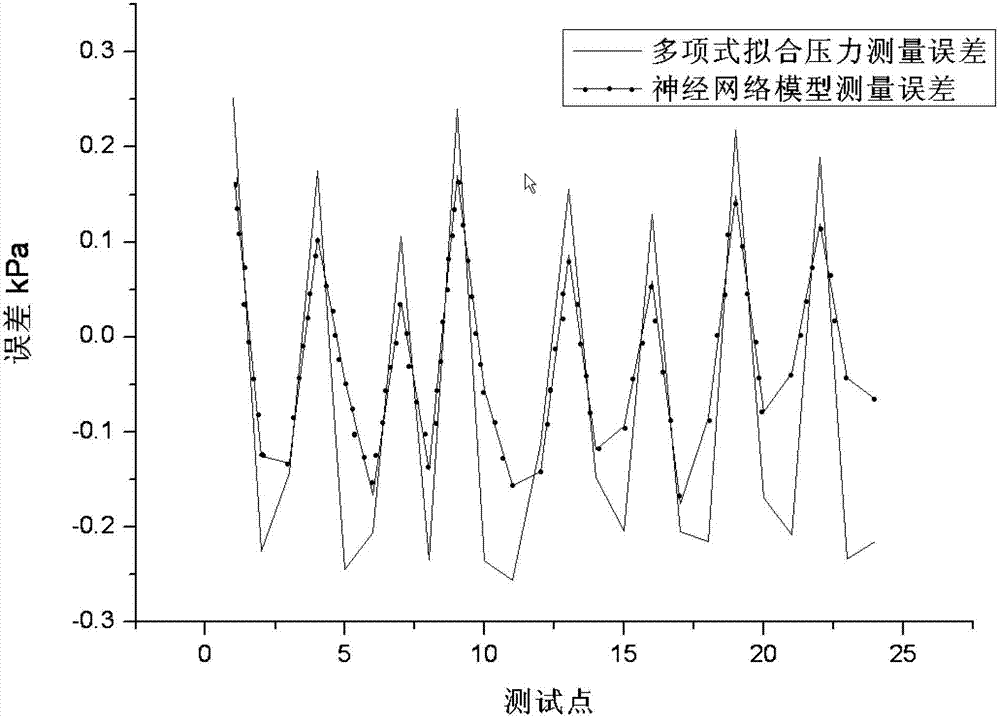

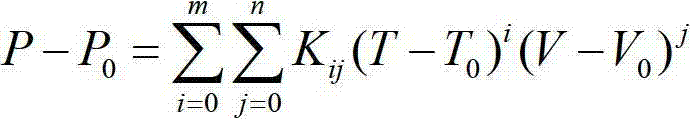

[0033] A BP neural network-based resonant cylinder pressure sensor calibration method, including the construction of a sensor BP neural network with a double hidden layer network structure, so that the input variables of the network structure are the output period T and temperature voltage V of the sensor, and the output variable is the pressure value P; Collect the output cycle and temperature voltage of the sensor under different temperature and different pressure input conditions; Collect the sensor output under different temperature and pressure conditions as the calibration and inspection sample points.

[0034] In the sensor BP neural network, the hyperbolic tangent S-type transfer function is used as the transfer function between the input layer and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com