Method for using multistage vibration isolation platform to improve optic loading imaging quality

A vibration isolation platform, imaging quality technology, applied in general control systems, instruments, adaptive control and other directions, can solve problems such as low accuracy and stability of payload imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

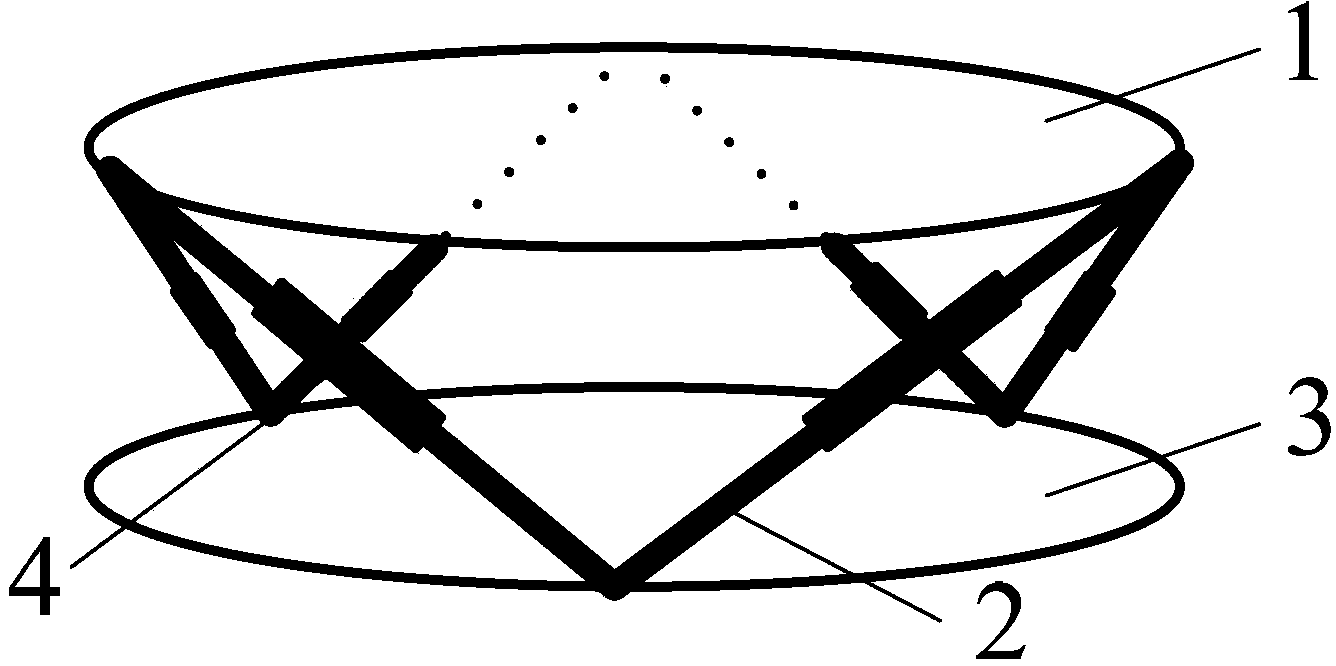

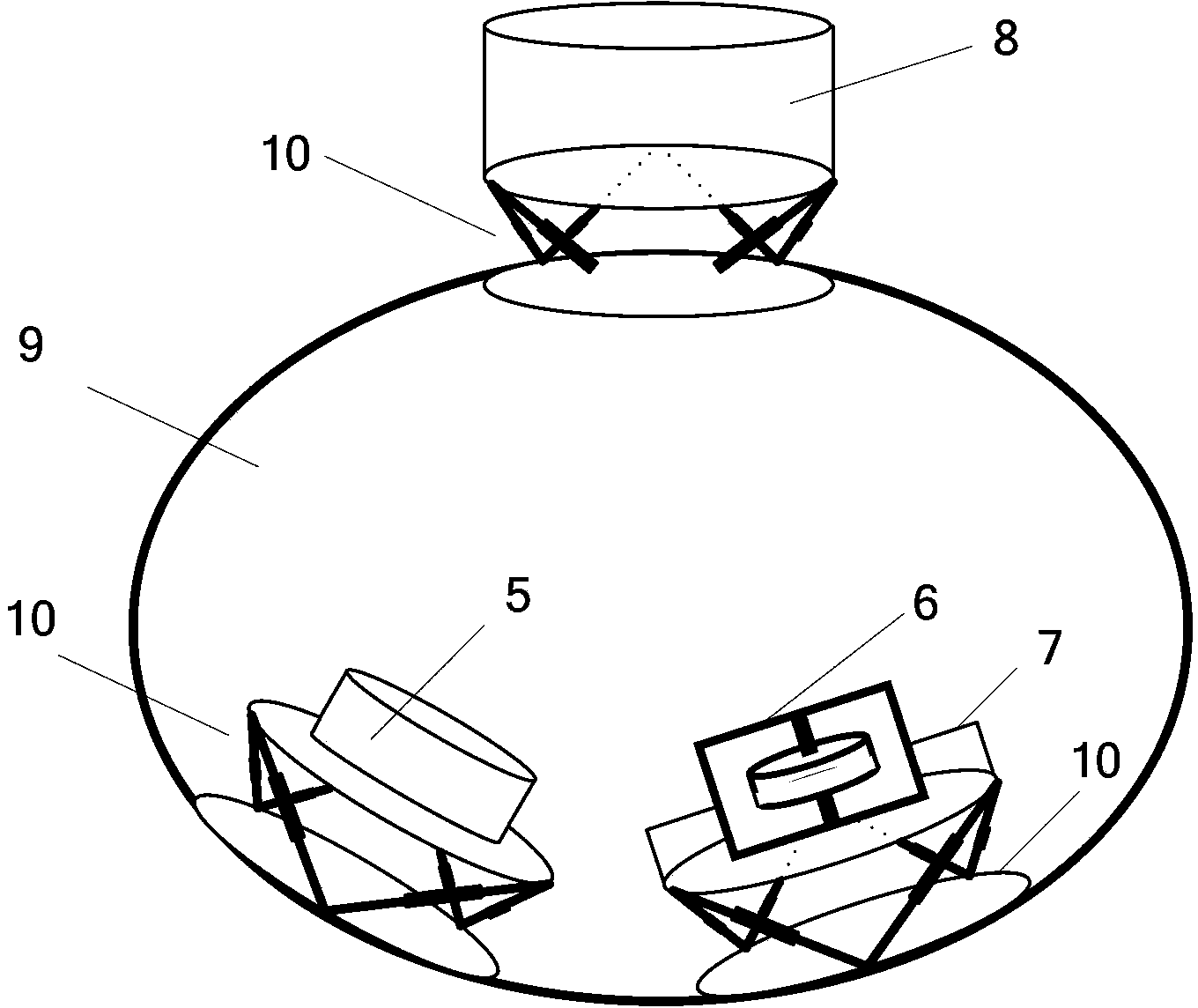

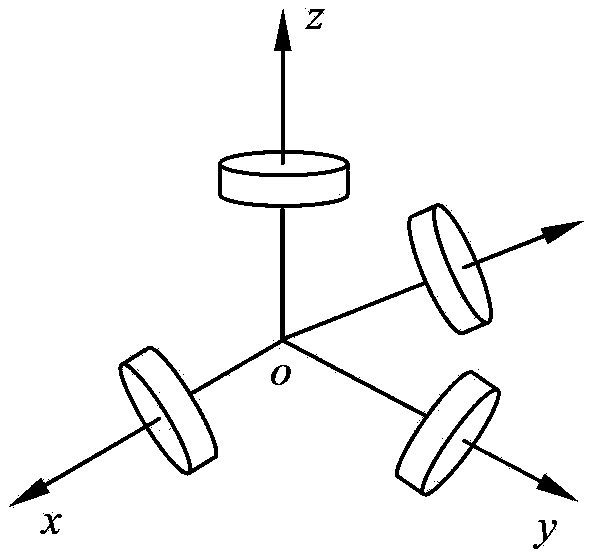

[0051] like figure 1 As shown, a vibration isolation platform includes: an upper platform 1, a lower platform 3, and a strut 2 connecting the upper platform 1 and the lower platform 3; the installation form of the vibration isolation platform on the satellite is as follows figure 2 As shown, it can be installed between satellite actuators such as flywheel 5 or control moment gyroscope 6 and satellite body 9, and between optical payload 8 and satellite body 9; when adding vibration isolation between flywheel 5 and satellite body 9 When the platform is installed, the upper platform of the vibration isolation platform can be fixedly connected with the flywheel housing to form a set of upper platform system; when using the vibration isolation platform between the control moment gyroscope 6 and the satellite body 9, a set Mounting frame 7, one end of mounting frame 7 is fixedly connected at the upper platform place of vibration-isolation platform, and the other end of mounting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com