A printed distributing board and a manufacture method of the same

A technology for printed wiring boards and manufacturing methods, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., which can solve the problems of overall shape limitation, poor manufacturing efficiency, etc., and achieve space saving , to achieve the effect of manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

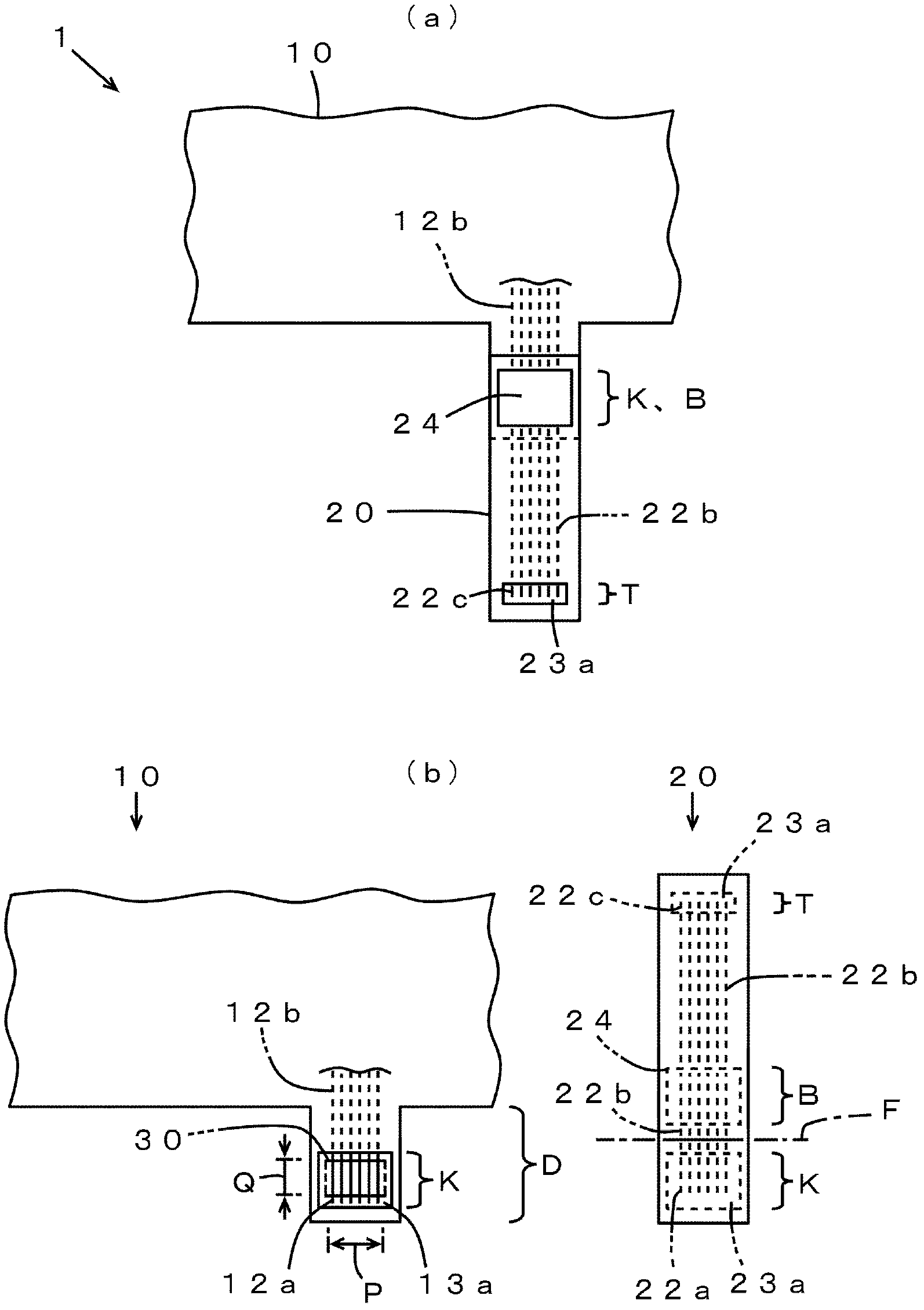

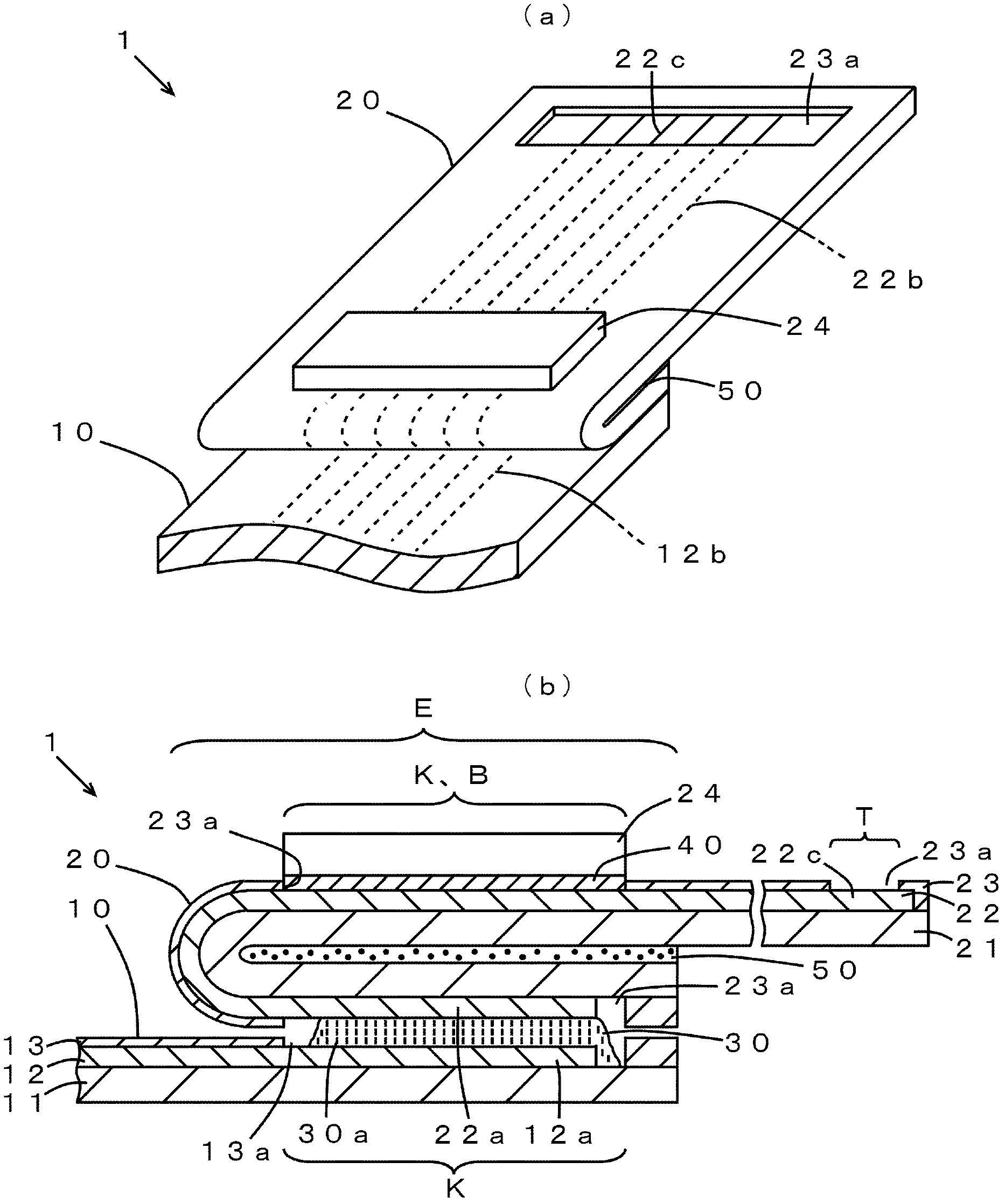

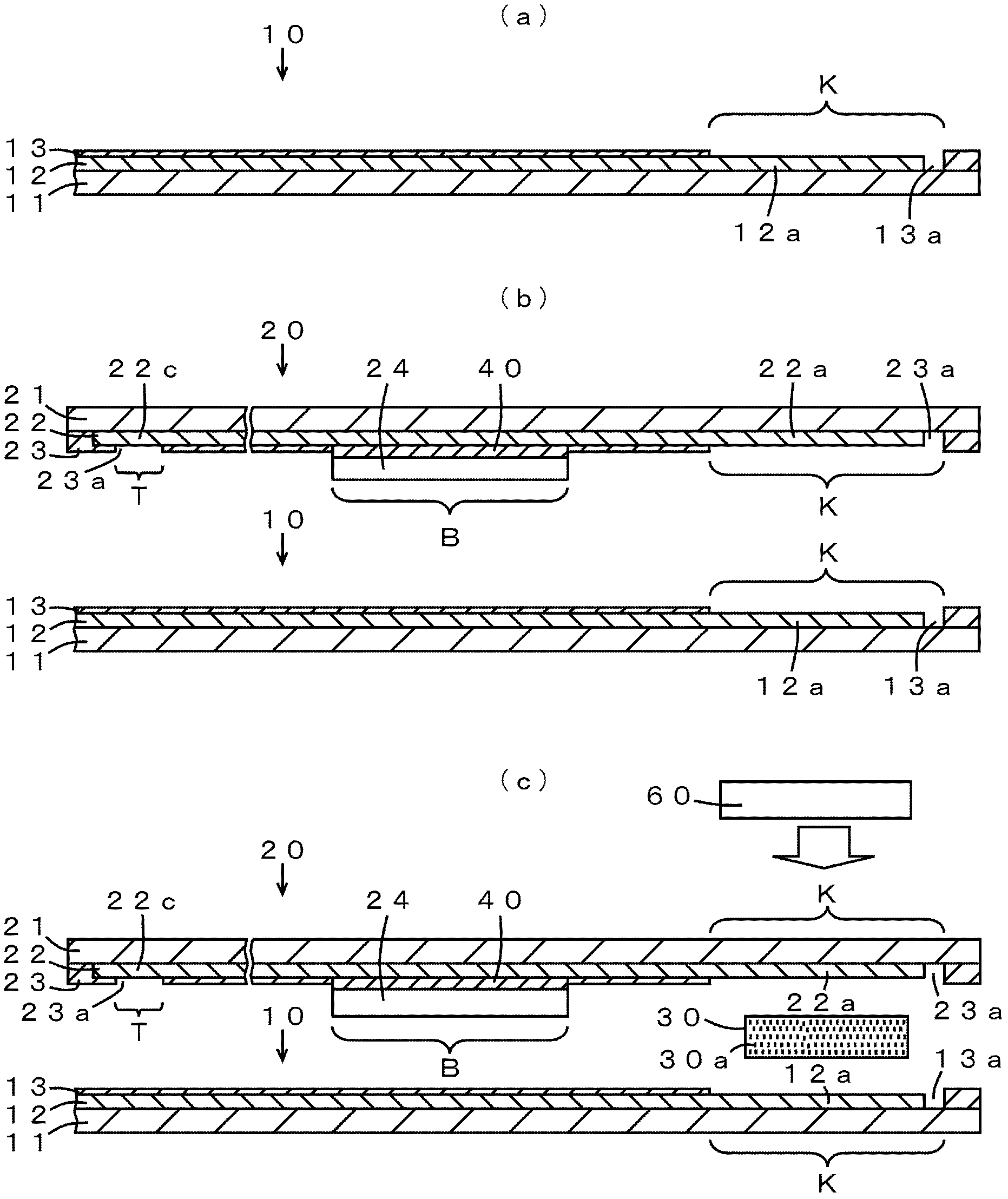

[0033] In order to understand this invention, the printed wiring board which concerns on embodiment of this invention, and the manufacturing method of this printed wiring board are demonstrated, referring drawings below. However, the following description is an embodiment of the present invention, and does not limit the contents described in the claims. First, refer to figure 1 , figure 2 , the printed wiring board according to the embodiment of the present invention will be described.

[0034]The printed wiring board 1 according to the embodiment of the present invention is, for example, figure 1 , figure 2 As shown, the main body 10 having the electrode forming region K and the electronic component mounting portion 20 having the electrode forming region K and the electronic component mounting region B are integrally electrically connected through an anisotropic conductive adhesive 30 and formed by printing. patch panel.

[0035] The above-mentioned main body portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com