Pulse valve for bag type dust collector and connecting structure and connecting method of pulse valve

A bag filter and pulse valve technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inconvenient use of wrenches or pipe wrenches, high installation size requirements, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

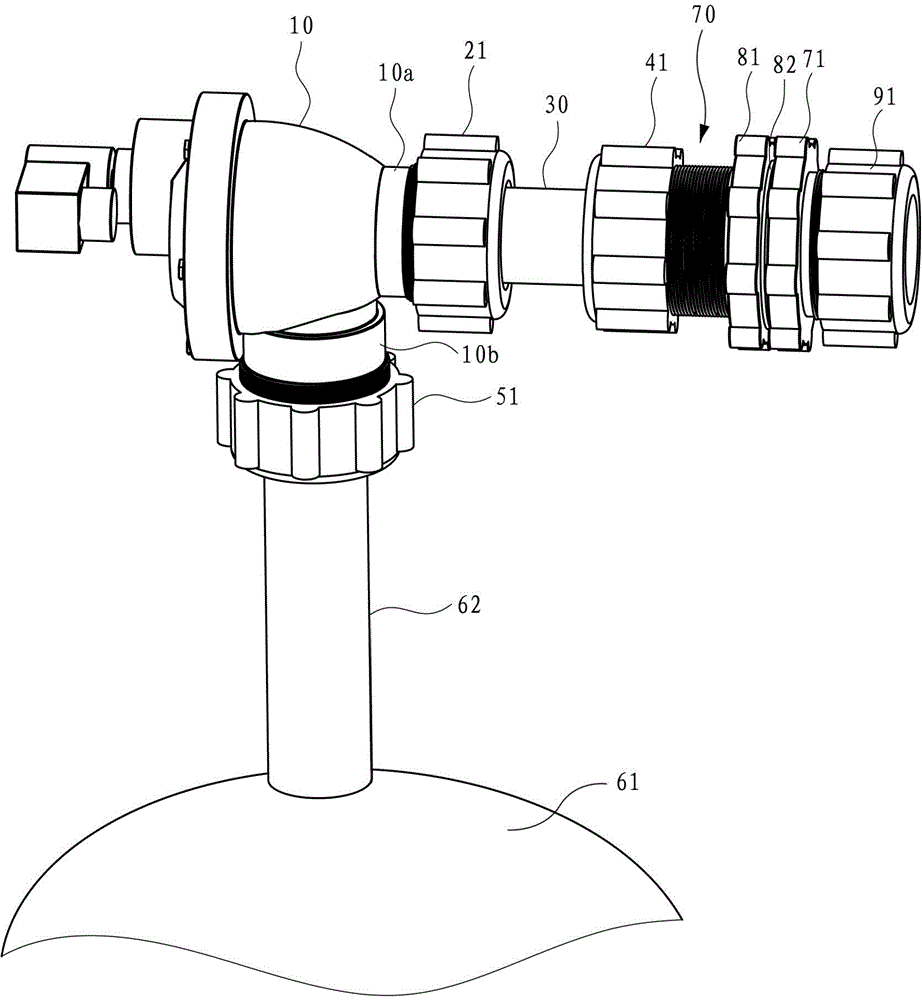

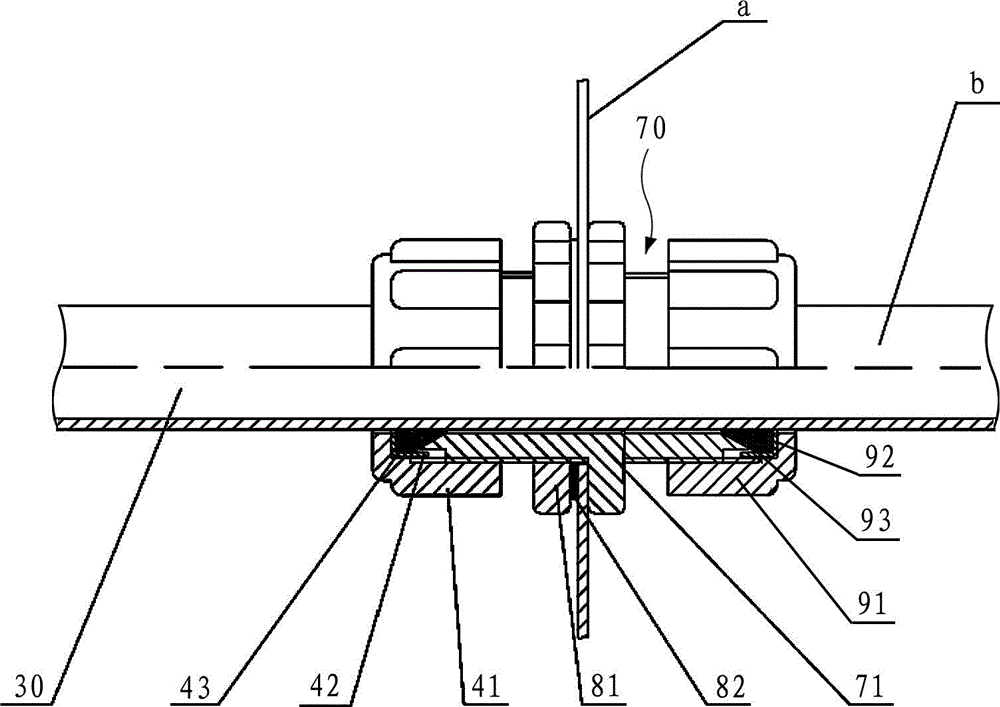

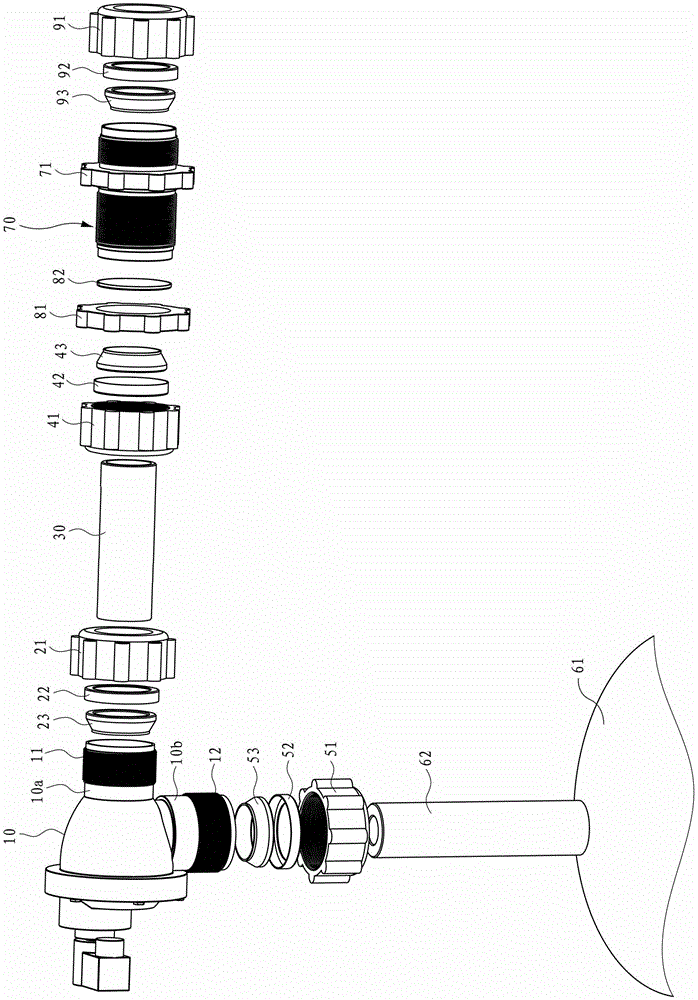

[0054] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. For ease of description, according to the flow direction of the compressed gas, the two ends of each component are respectively described as an inlet end and an outlet end. Moreover, words such as "first", "second", and "third" described below are only for convenience of description, that is, additional words to distinguish parts with the same name, and are not used to limit the scope of protection. .

[0055] First, the case of using the male thread pulse valve of the present invention will be described.

[0056] Such as Figure 5 As shown, the connection structure of the externally threaded pulse valve of the present invention is as follows. The air outlet pipe 110 of the externally threaded pulse valve 100 is sealingly plugged and connected to the inlet end of the wall-piercing pipe 300 . At this time, the first compression nut 210 can be sealingly inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com