Automatic centering fixture for workpiece with revolution boss and/or hole

An automatic centering and workpiece technology, applied in the direction of metal processing machinery parts, clamping, positioning devices, etc., can solve the problems of inability to adjust, difficult to ensure accurate centering, poor flexibility, etc., to achieve reliable locking, reduce centering and Locking workload and time, accurate centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

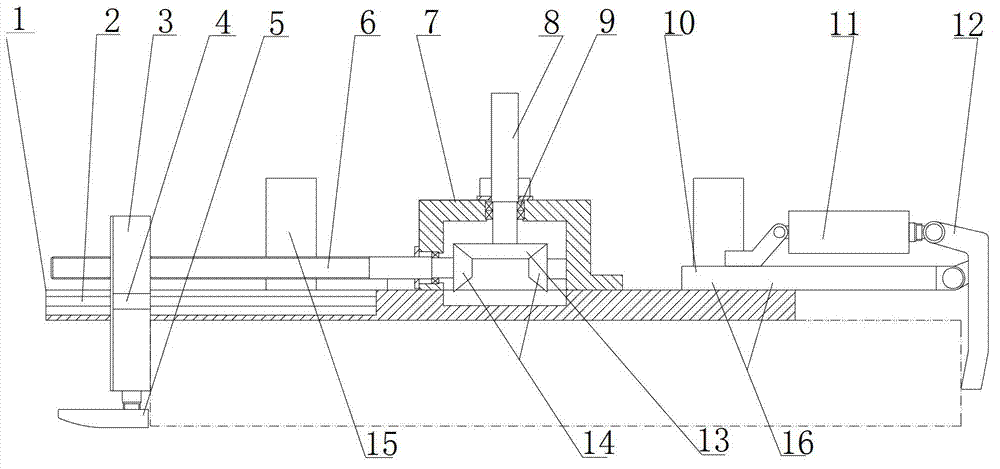

[0040] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0041] In this embodiment, a workpiece with a cylindrical boss and a circular through hole is taken as an example for illustration. The workpiece can be clamped internally from the inside of the through hole, or centered from the outer contour of the cylindrical boss. . However, the present invention is not limited to the above-mentioned workpieces, and can also be of other types, as long as they have a rotary boss or an inner hole (such as a rotary inner hole, preferably a through hole).

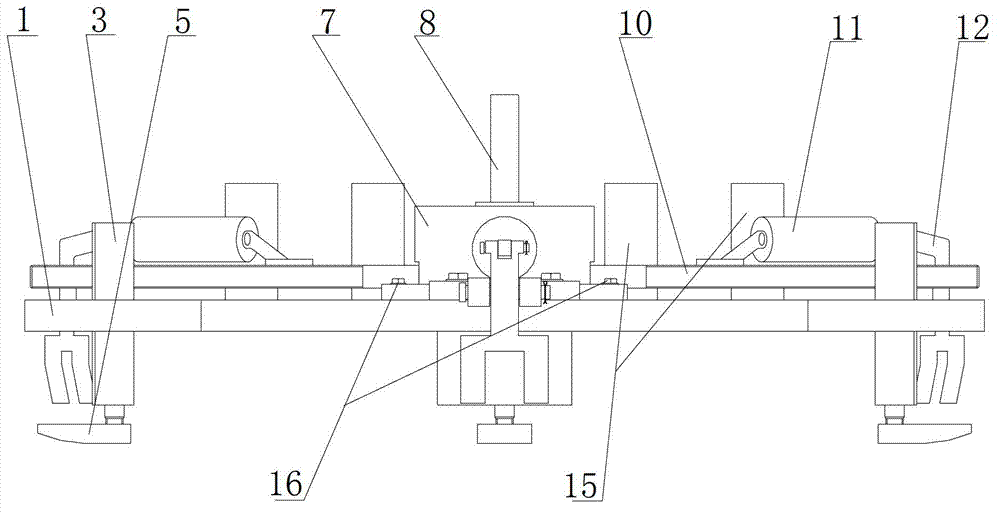

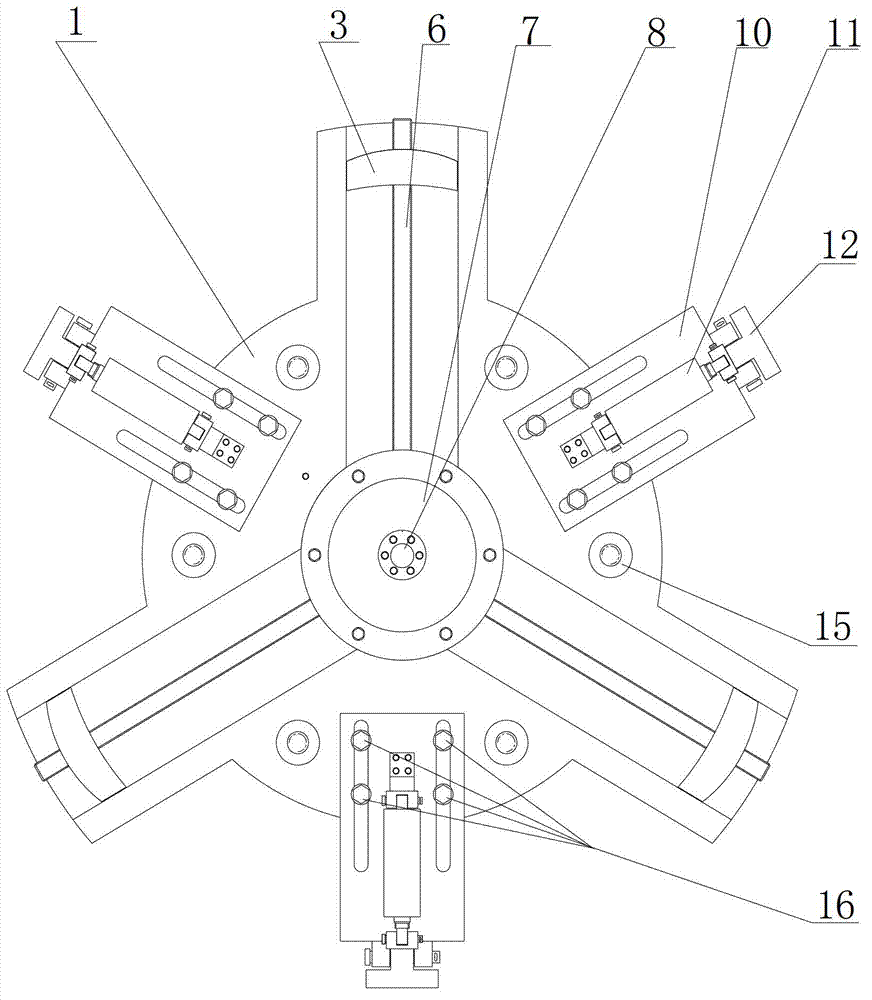

[0042] like Figure 1-3 , The self-centering fixture in this embodiment includes a chassis 1, a guide rail 2, a centering drive device, 3 self-centering slides, an internal clamping device and an external clamping device.

[0043] There are multiple sets of guide rails 2, which are evenly distributed radially and installed on the chassis 1. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com