Exhaust type oil outlet device with built-in oil tanks

An oil outlet and oil tank technology, applied in locomotives and other directions, can solve problems such as reducing use efficiency, prolonging oil injection time, delaying construction period, etc., to facilitate monitoring and maintenance, improve oil injection quality, and eliminate potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

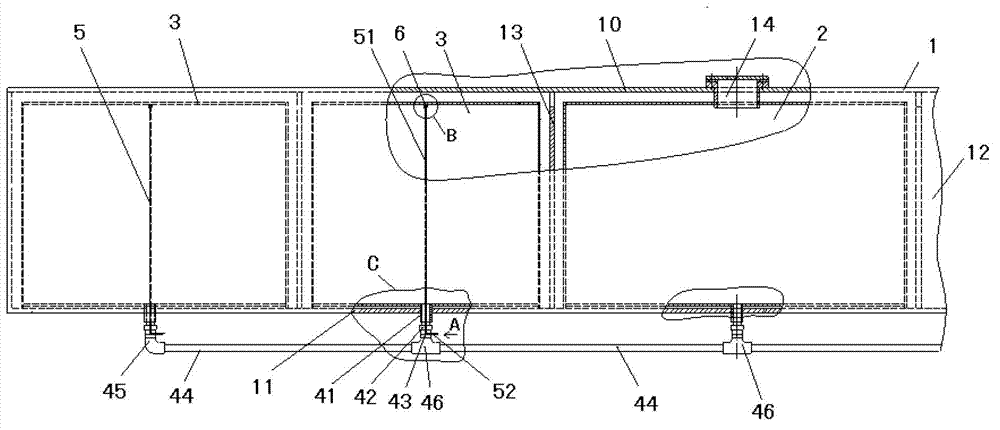

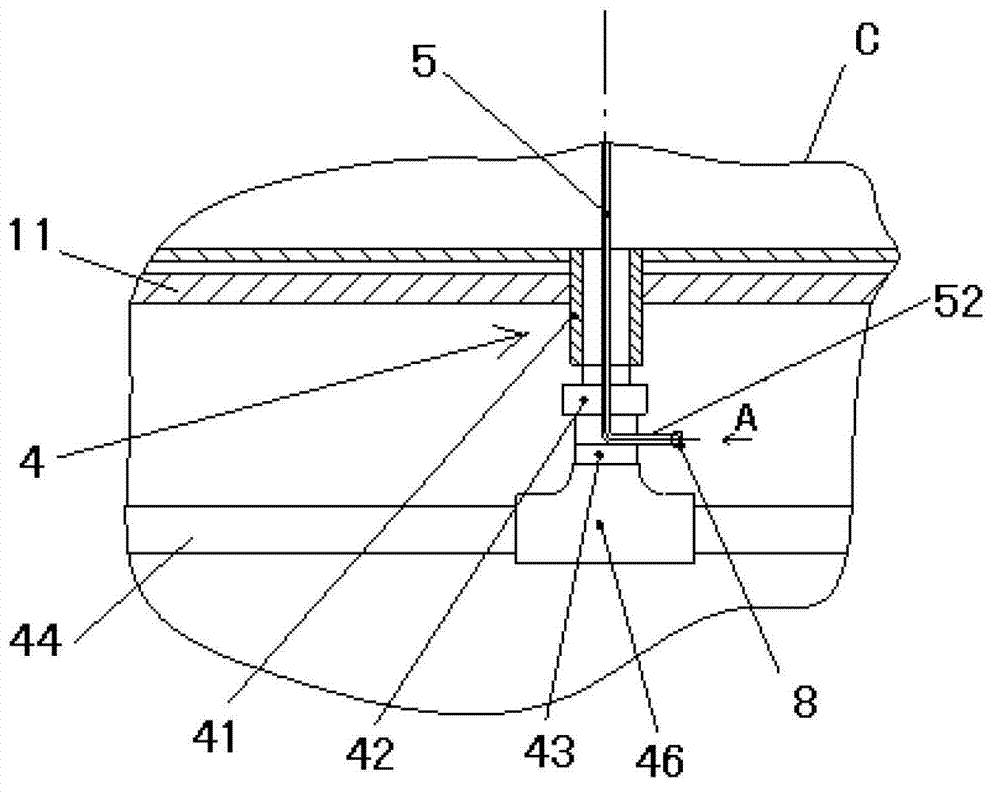

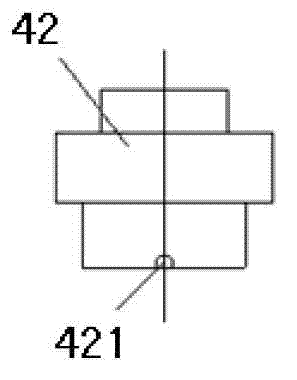

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a closed structure 1, a built-in main fuel tank 2 and several built-in auxiliary fuel tanks 3; the closed structure 1 is formed by welding an upper cover plate 10, a lower cover plate 11, two webs 12 and several partitions 13 A number of independent enclosed structural spaces, in which a built-in main fuel tank 2 or a built-in auxiliary fuel tank 3 is placed as required, and the top of the built-in main fuel tank 2 is provided with an oil filling port 14 communicating with the upper cover plate 10 of the closed structure 1, The bottom of the built-in main oil tank 2 and each built-in auxiliary oil tank 3 are respectively provided with an oil outlet communicating with the lower cover plate 11 of the closed structure 1, and an oil outlet device 4 is arranged at each oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com